Method of external application medicine patch on-line die cutting

A medicine patch and laser technology, which is applied to laser welding equipment, devices for making medicines into special physical or taking forms, manufacturing tools, etc., can solve the problems of slow cutting speed, low work efficiency, difficulty, etc., and achieve improvement The effect of fast production speed and cutting speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

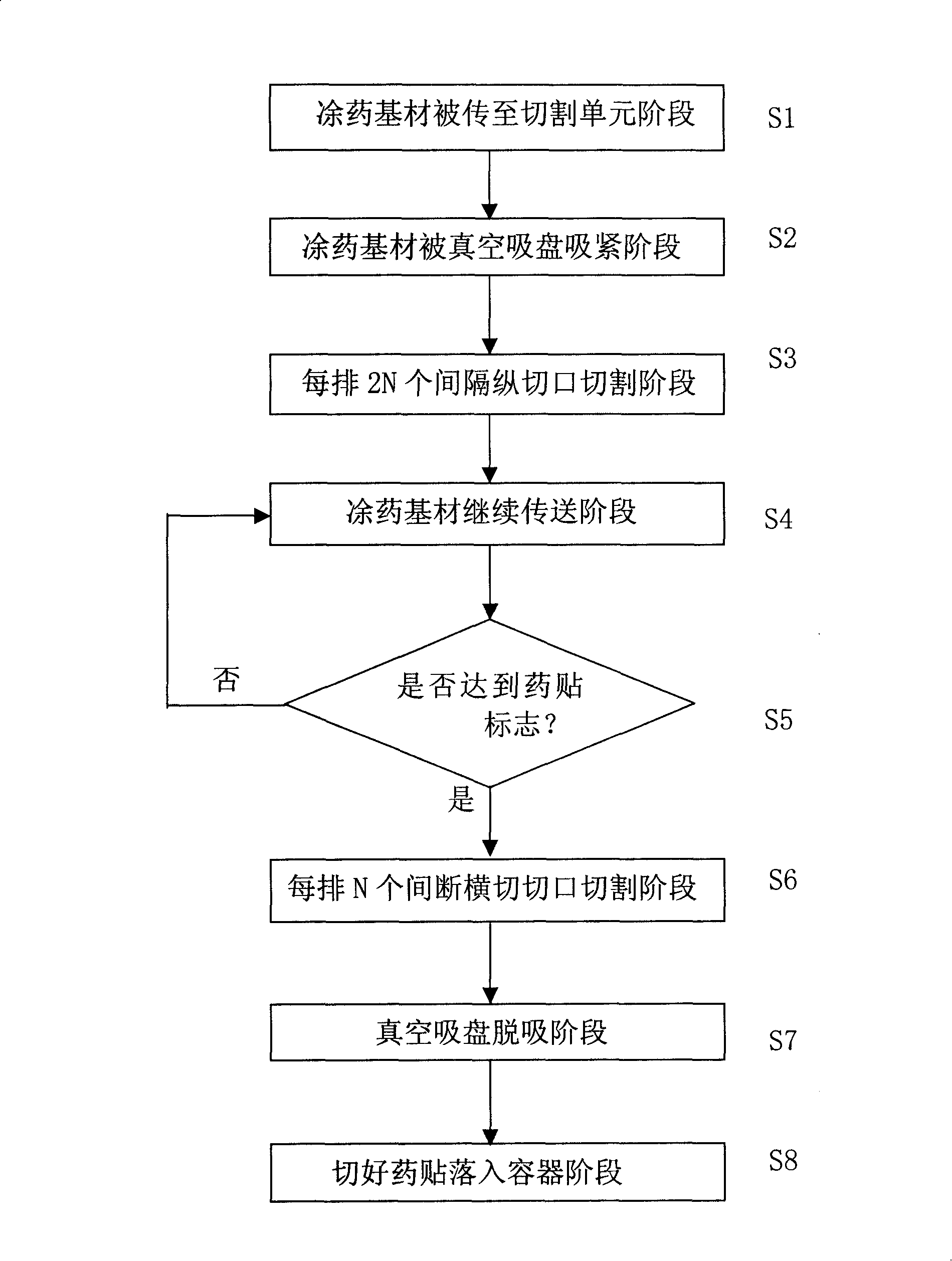

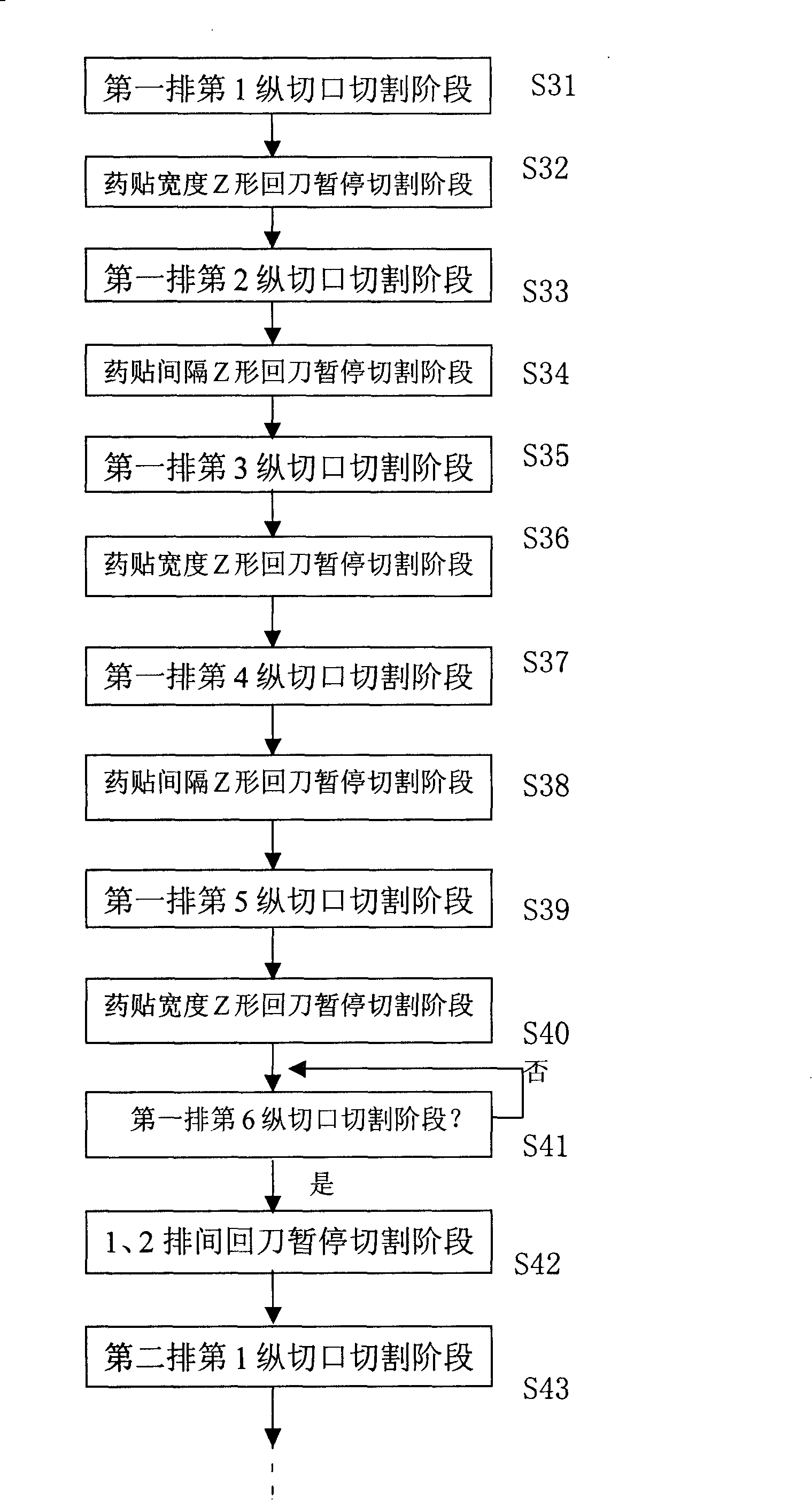

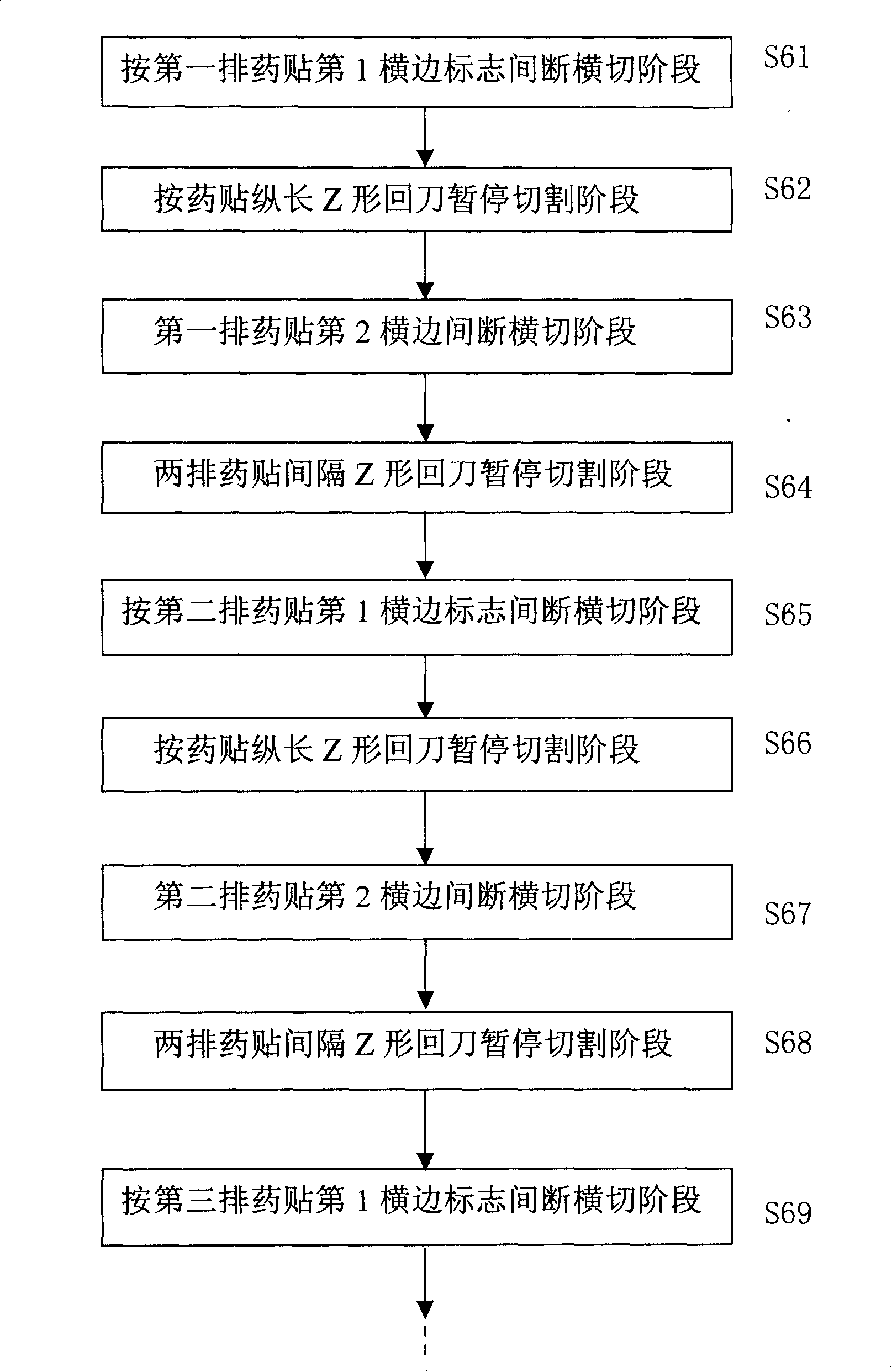

[0027] In order to further illustrate the content, technical characteristics and effects of the present invention, give the following examples again and illustrate as follows in conjunction with the accompanying drawings: figure 1 As shown in -5, the laser on-line die-cutting method for external drug patches of the present invention includes: the drug-coated base material of the drug patch is transferred to the cutting unit stage S1; the drug-coated base material is sucked tightly by a vacuum suction cup stage S2; Interval vertical slit cutting stage S3; drug-coated base material continues to convey stage S4; cutting stage; whether it reaches the drug patch mark judgment stage S5; if yes, perform N intermittent transverse slit cutting stage S6 for each row; vacuum suction cup desuction stage S7; The cut-out patch falls into the collection container stage S8.

[0028] Its 2N spaced slit cutting stage is controlled by a laser slitting head according to the microcomputer-controll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com