Method for removing organics and ammonia nitrogen from aquaculture water

A technology for aquaculture water and organic matter, applied in chemical instruments and methods, sustainable biological treatment, biological water/sewage treatment, etc., can solve the problems of low efficiency and high treatment cost, achieve economical and efficient removal, increase regeneration rate and regeneration rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

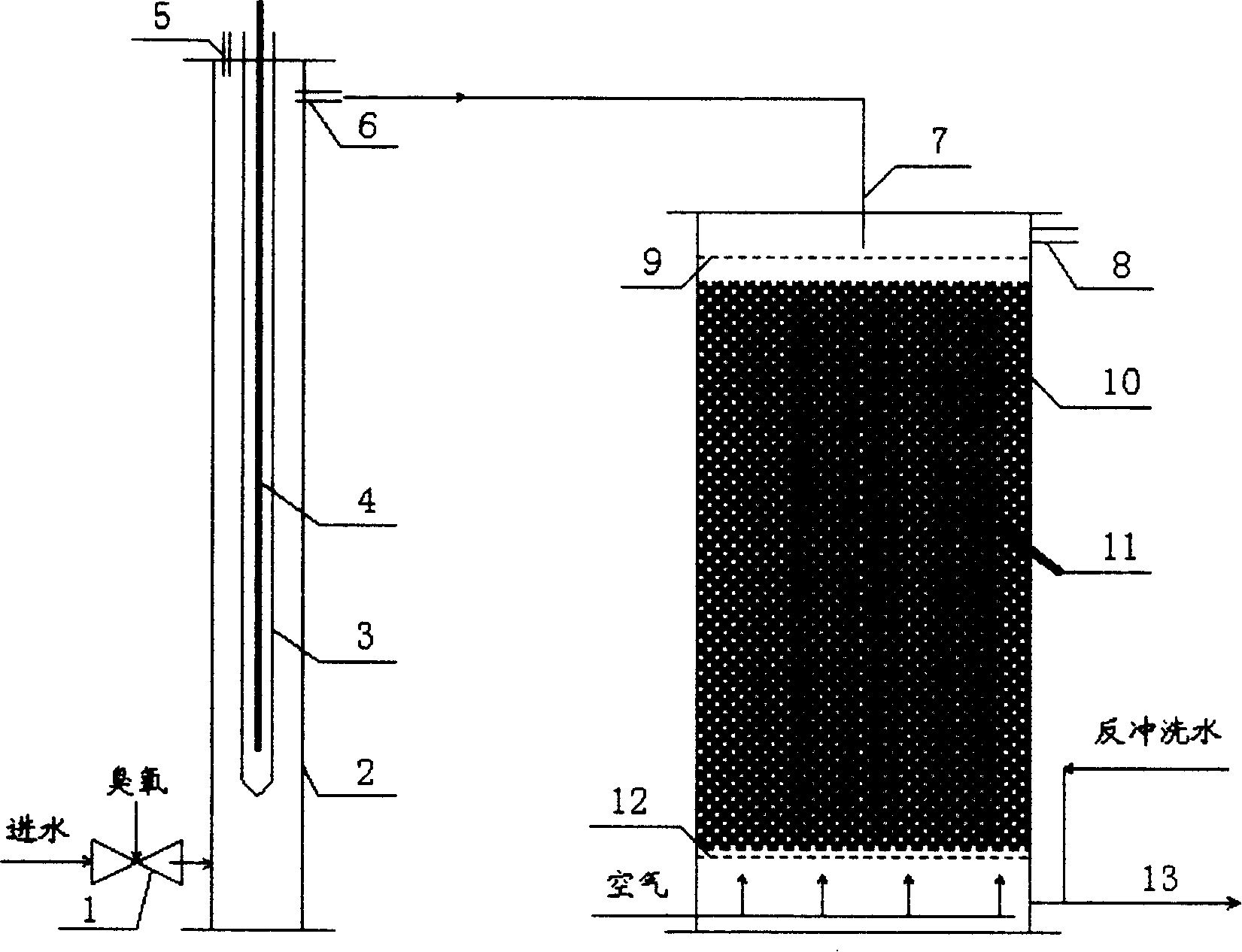

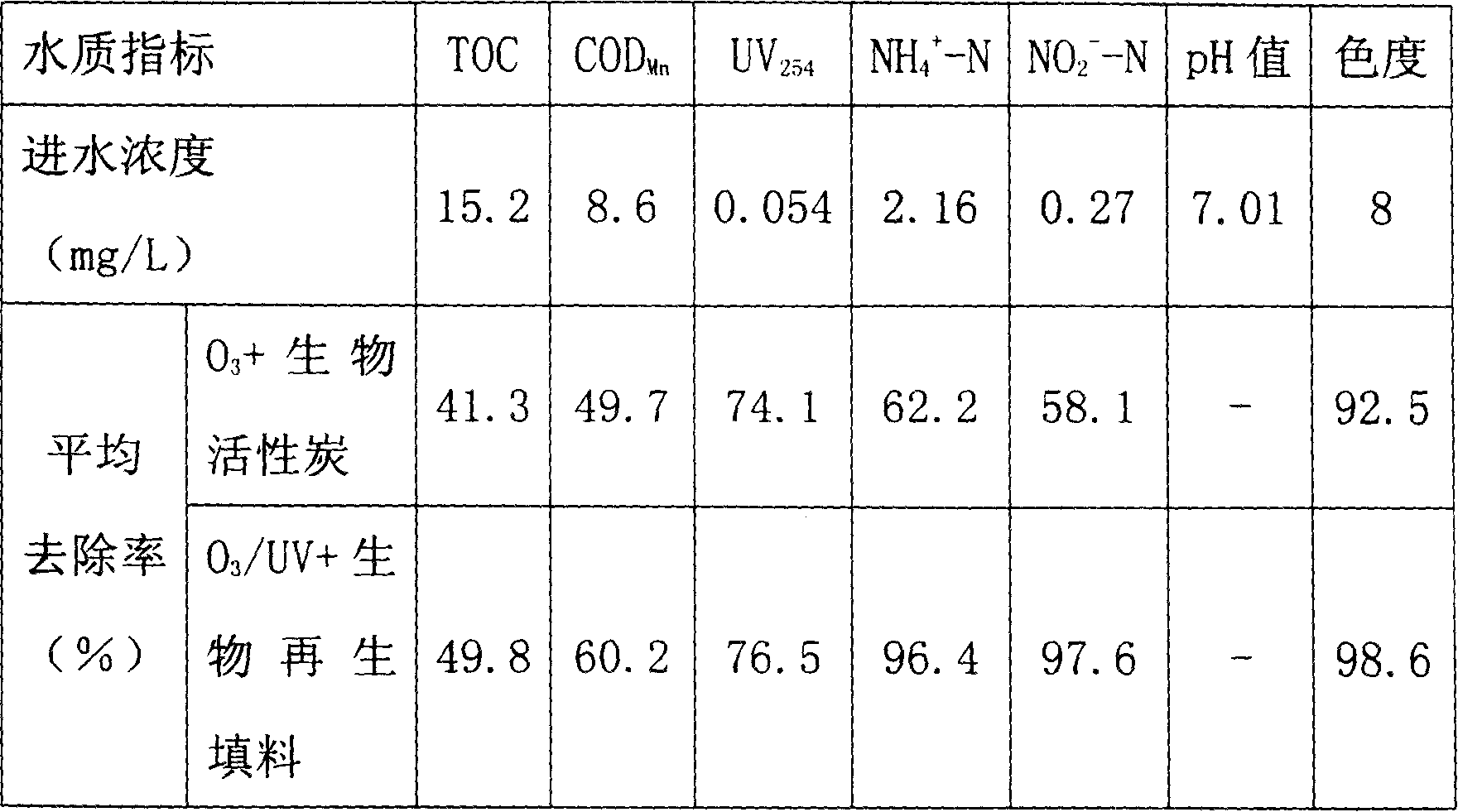

[0008] Example: The method for purifying circulating aquaculture water by ozone / ultraviolet-biological regeneration filler is as shown in the attached drawings. / The lower part of the UV combined oxidation reaction barrel 2 enters the reaction barrel 2; the amount of ozone added in the ozone / UV combined oxidation reaction barrel is determined between 0.5-5 mg / L according to the water quality, such as 2 mg / L; ozone / UV The ultraviolet lamp group 4 with a built-in outer quartz sleeve 3 in the center of the combined oxidation reaction barrel 2 is composed of a plurality of 30W hot cathode ultraviolet low-pressure mercury lamps. That is, the ultraviolet radiation intensity in the far distance of the ozone / ultraviolet combined oxidation reaction barrel should be greater than 15000μW / cm 2 ; Water and ozone gas flow upward through the ozone / ultraviolet combined oxidation reaction tank 2, the hydraulic retention time is 5min, and the refractory organic matter and ammonia nitrogen in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com