Towing cable for down-hole digger and method for preparing

A cable and machine-used technology, which is applied in the field of towing cables for underground mining machines, can solve the problems of large outer diameter of the cable and affect the bending and winding performance of the cable, so as to achieve the enhancement of the overall tensile capacity, improve the tensile and winding capacity, The effect of increasing the tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

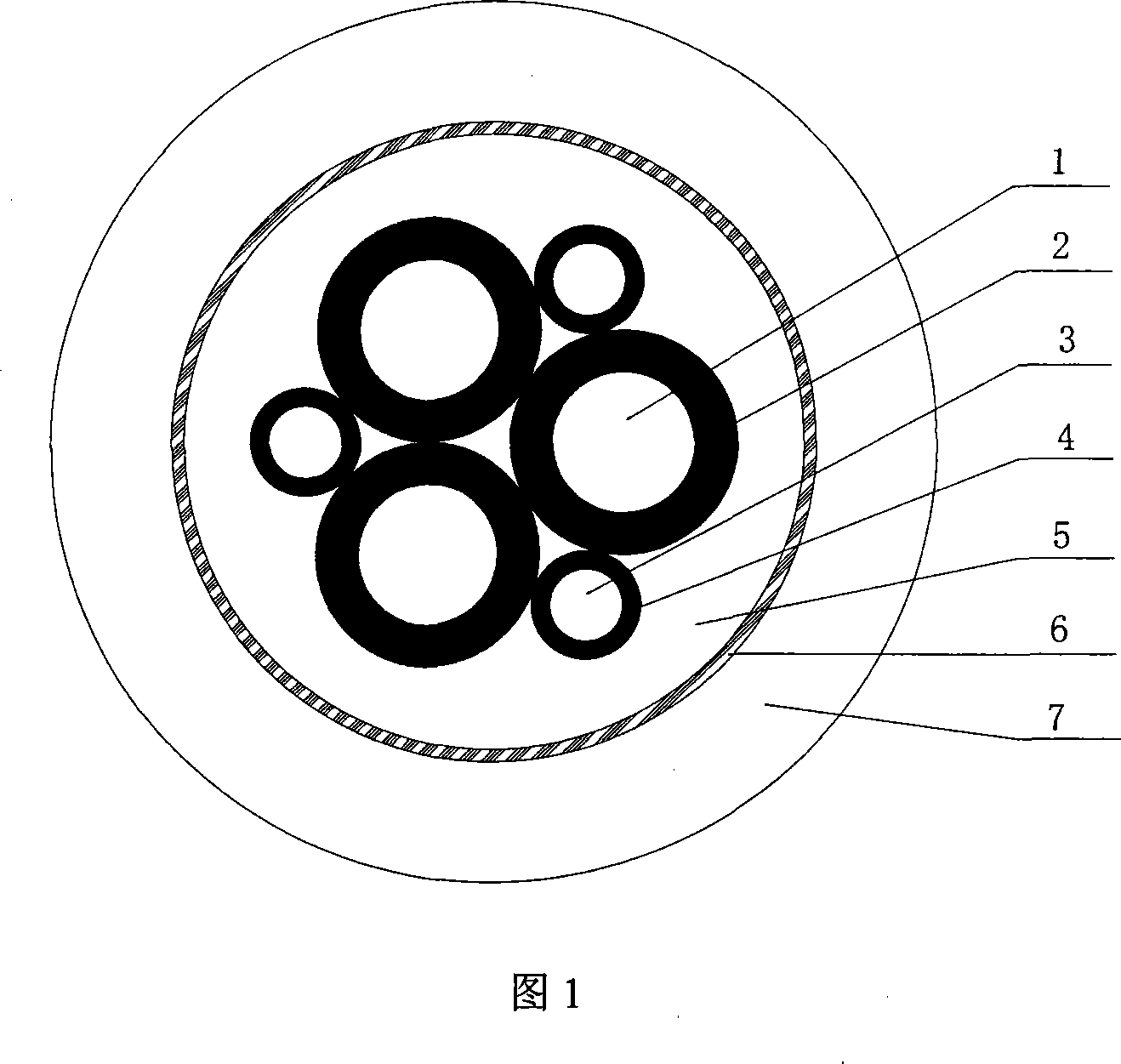

[0026]Embodiment: Referring to the accompanying drawings, the towing cable for the underground mining machine of the present invention adopts tinned copper wires of types 5 and 6, and adopts the same direction twisting method according to bundle wires and re-twisting, and the pitch ratio is controlled below 12. Twisted into the main core soft conductor 1, the ground core is divided into three parts according to the cross-section, bundled and re-twisted respectively into the ground conductor 3, the main core and the ground core are extruded with ethylene-propylene rubber insulation 2 and 4 respectively, Place the three ground wire cores in the gaps between the three main wire cores, and twist them into cables according to the "3+3" structure. The pitch ratio of the cables is controlled below 8 times. The outside of the stranded cable core is not filled, and the inner sheath 5 of chlorosulfonated polyethylene rubber is directly extruded by means of external extrusion, and the inn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com