Ultrafast recovery diode

A recovery diode and diode technology, applied in the direction of electrical components, electric solid devices, circuits, etc., can solve the problems of unsuitable structure for high operating frequency, large size of the original packaging form, unsuitable for application needs, etc., to achieve compact structure, reduce Circuit connection, the effect of reducing the temperature rise of the operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

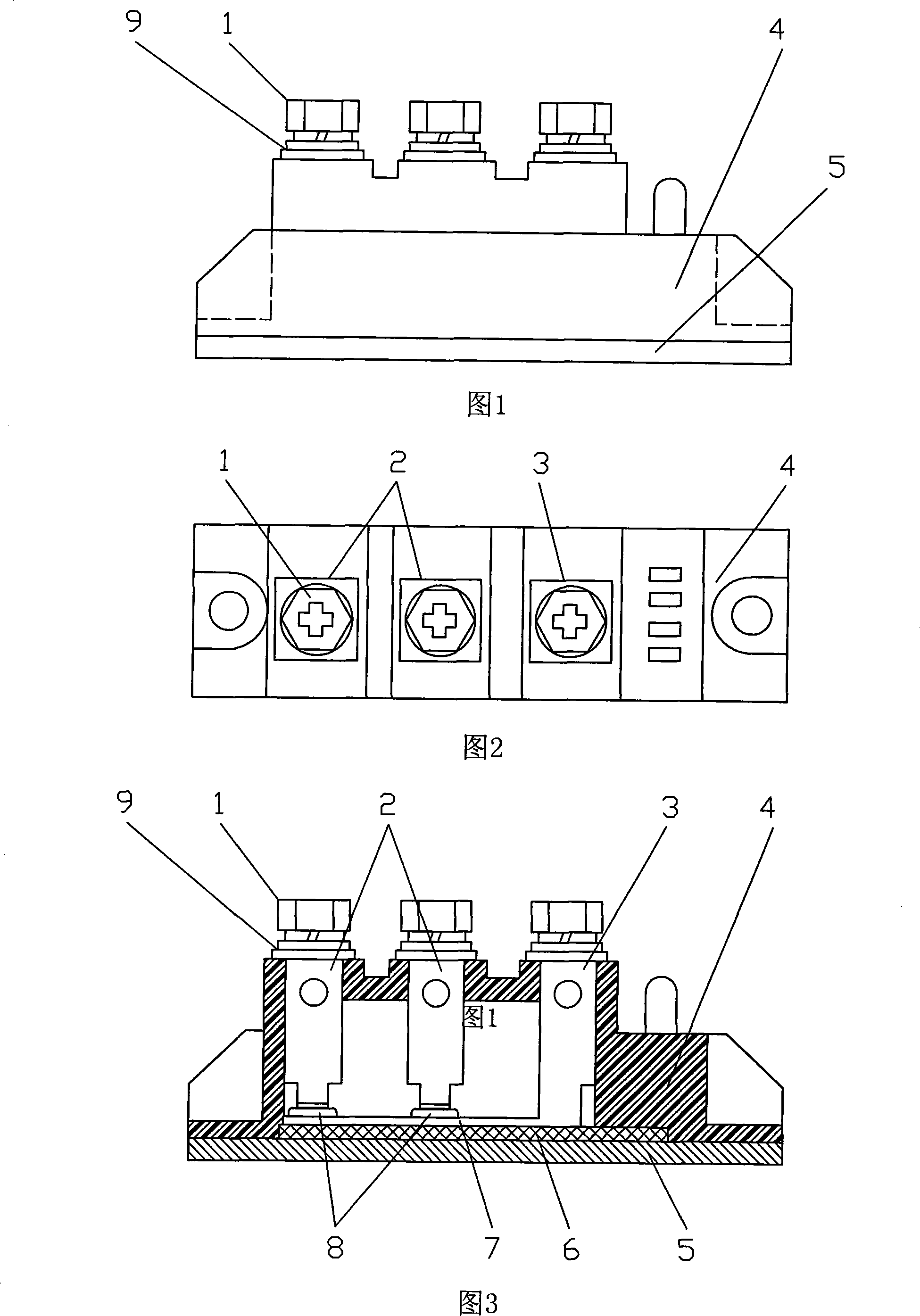

[0017] Referring to Fig. 1, for an ultrafast recovery diode, two diode chips 8 are arranged in the insulating casing 4, and the cathodes of the diode chips 8 are welded on the copper electrode plate 7 and then welded to the beryllium oxide sheet 6 and the copper base plate 5 in turn , the anode is led out by the conductive sheet 2 respectively, and the copper electrode plate 7 is led out by the cathode conductive sheet 3 . The anode of the diode chip 8 and the anode conductive sheet 2 are also fixed by welding. The soldering is lead-tin soldering. Gaskets 9 and nuts 1 are provided on the upper ends of each conductive sheet 2 and 3 for electrical connection with an external circuit.

[0018] It should be understood that: the above-mentioned embodiments are only descriptions of the present invention, rather than limitations of the present invention, and any inventions that do not exceed the spirit of the present invention fall within the protection scope of the present inventio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com