Self-healing polymers

A technology of polymers and polymerization agents, which is applied in the field of composite materials and preparation of composite materials, and can solve problems such as low catalyst loading efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

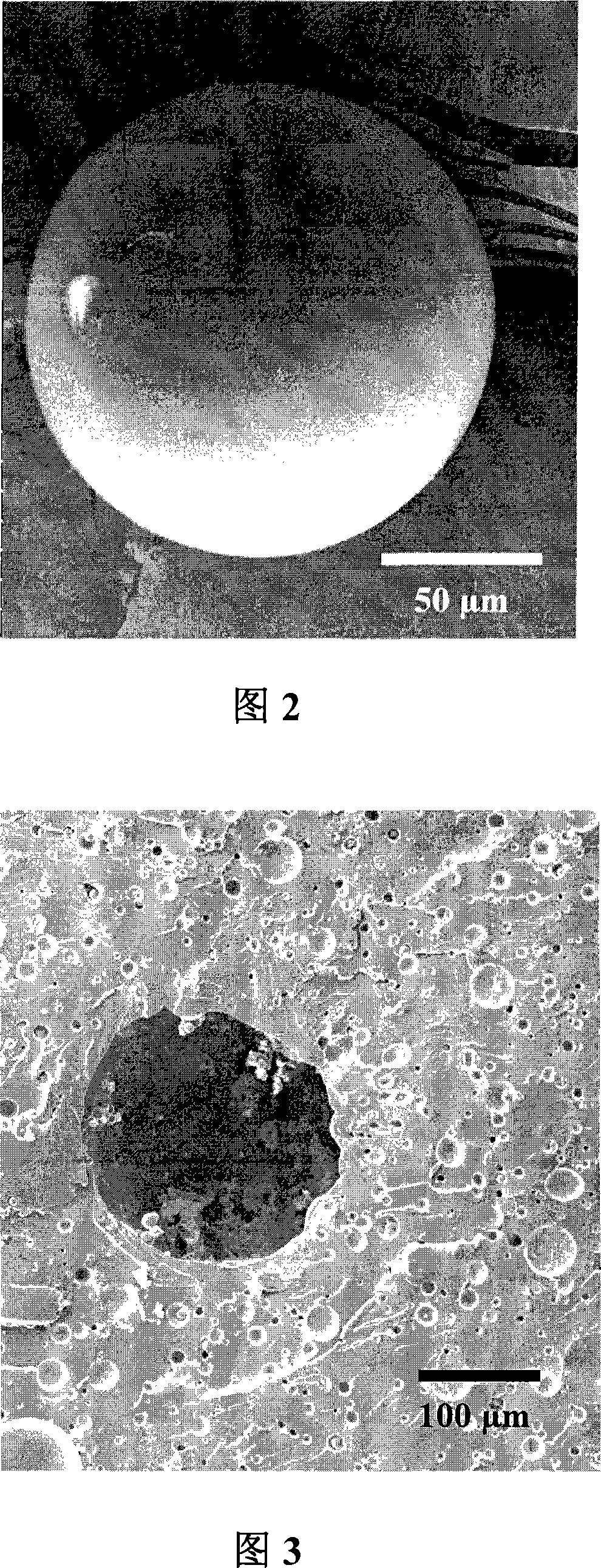

[0058] Example 1: Forming Capsules Containing Activators

[0059] Dibutyltin dilaurate was encapsulated in polyurethane microcapsules formed by interfacial polymerization. By dissolving toluene 2,4-diisocyanate (TDI, Aldrich, 22.0g, mp=19.5-21.5°C) in cyclohexanone (142g, bp 760 =155.6°C) to synthesize the urethane prepolymer. The diol reactant 1,4-butanediol (5.0 g) was added to this mixture stirred using a syringe pump at a rate of 5 ml / min, and the reaction mixture was stirred and heated at 80° C. for 24 hours. To avoid gel formation during microencapsulation, the molar ratio of TDI to 1,4-butanediol was kept below 2.3. Once the prepolymer was formed, cyclohexanone was evaporated under vacuum at 100°C. Urethane prepolymers have an excess of isocyanate functionality that can be reacted with chain extenders to form higher molecular weight polymers. The isocyanate functional group in the urethane prepolymer is determined by titration, followed by ASTM D2572-97 determinatio...

Embodiment 2

[0061] Example 2: Formation of epoxy vinyl esters

[0062] Epoxy vinyl ester polymers were formed without the addition of polymerizing agents or microcapsules, and were used as control materials in tests performed on the composites. The epoxy vinyl ester polymer is formed from an epoxy vinyl ester composition which is a brominated bisphenol-A vinyl ester composition DERAKANE 510A-40 (ASHLAND; Dublin, OH). DERAKANE 510A-40 prepolymer was mixed with 1 wt% benzoyl peroxide (BPO) initiator until the BPO was dissolved, then 0.1 wt% dimethylaniline (DMA) accelerator was added. After degassing the mixture under vacuum, it was poured into sealed silicone rubber molds and cured at room temperature for 24 hours and then at 50° C. for another 24 hours. Two types of control samples were formed in the presence and absence of adhesion promoter. For a control sample formed with an adhesion promoter, 4 wt% of methacryloxypropyltriethoxysilane was added to the prepolymer.

Embodiment 3

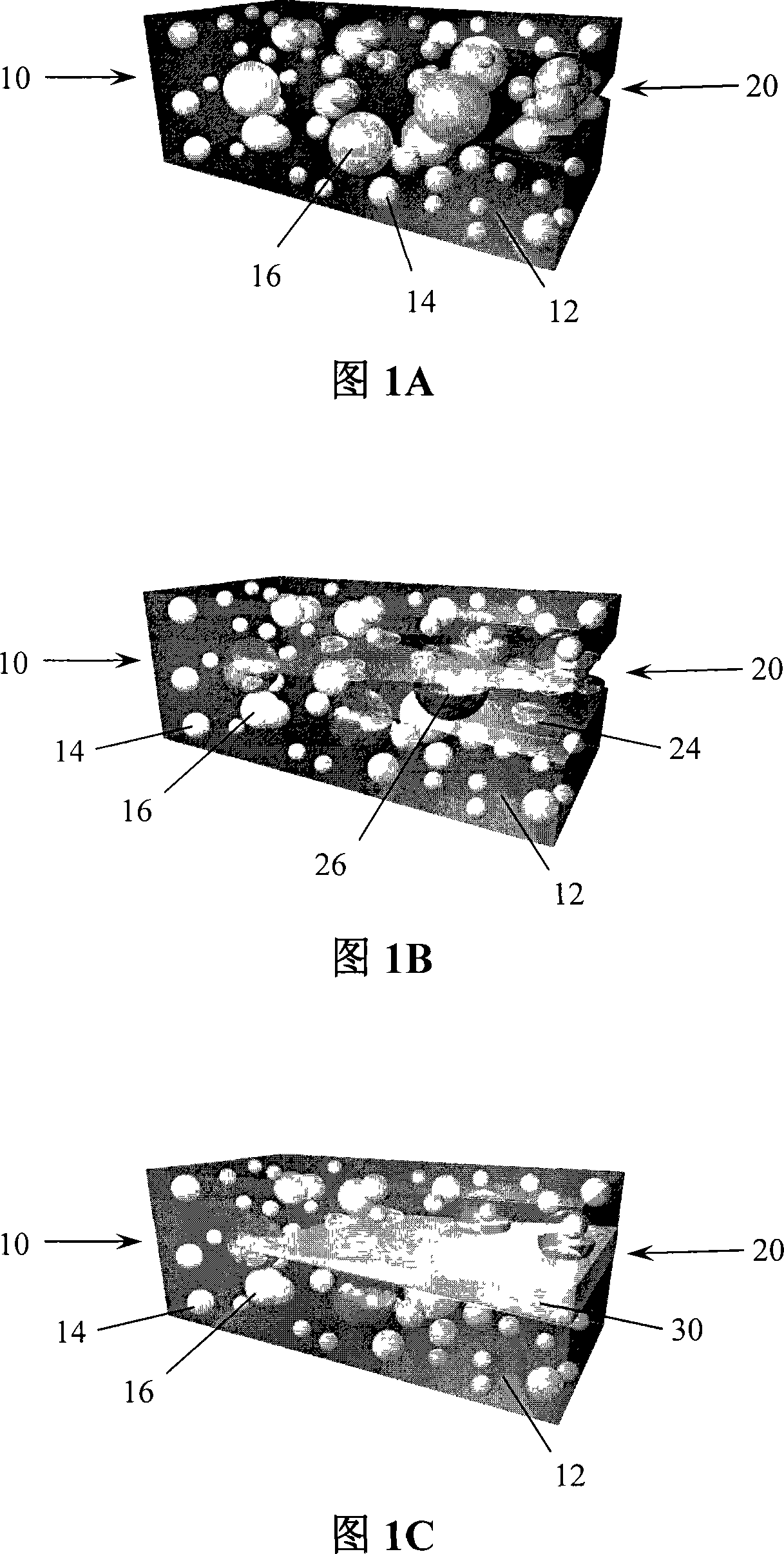

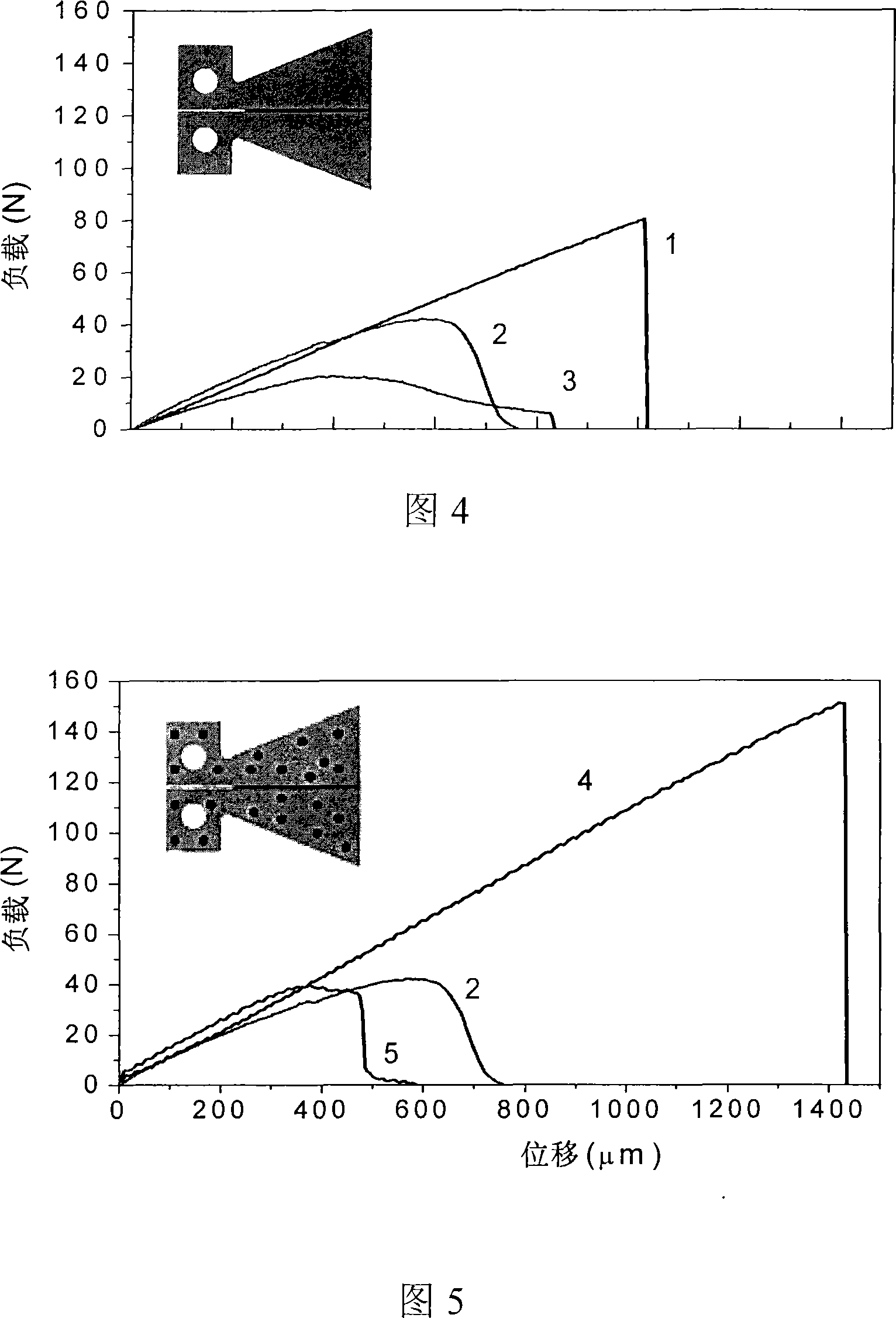

[0063] Example 3: Forming Composite Materials

[0064] A composite was formed by incorporating the polymerizing agent and the microcapsules of Example 1 into an epoxy vinyl ester polymer. The epoxy vinyl ester polymer was formed from a brominated bisphenol-A based vinyl ester composition DERAKANE 510A-40 (ASHLAND; Dublin, OH) containing about 38% styrene monomer. The DERAKANE 510A-40 prepolymer was mixed with 1 wt% benzoyl peroxide (BPO) initiator until the BPO dissolved. A mixture of HOPDMS and PDES was added to the prepolymer mixture at a mechanical stirring rate of 600 rpm, followed by degassing under vacuum. Afterwards, the microcapsules of Example 1 were added, and 0.1 wt% dimethylaniline (DMA) accelerator was added, followed by another degassing step. The mixture was then poured into sealed silicone rubber molds and cured at room temperature for 24 hours and then at 50 °C for an additional 24 hours.

[0065] The functionalized polysiloxanes HOPDMS and PDES are not mis...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com