Preparation method for tobacco extracting

A technology for tobacco extract and tobacco leaves, which is applied in the field of preparation of tobacco extract, can solve the problems that physical indicators do not meet production and processing requirements, the preparation process and equipment used are complicated, and the development of the tobacco industry is hindered, and excellent stability and repeatability are achieved. Sex, the method is simple and easy to implement, and the effect of strengthening the momentum

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

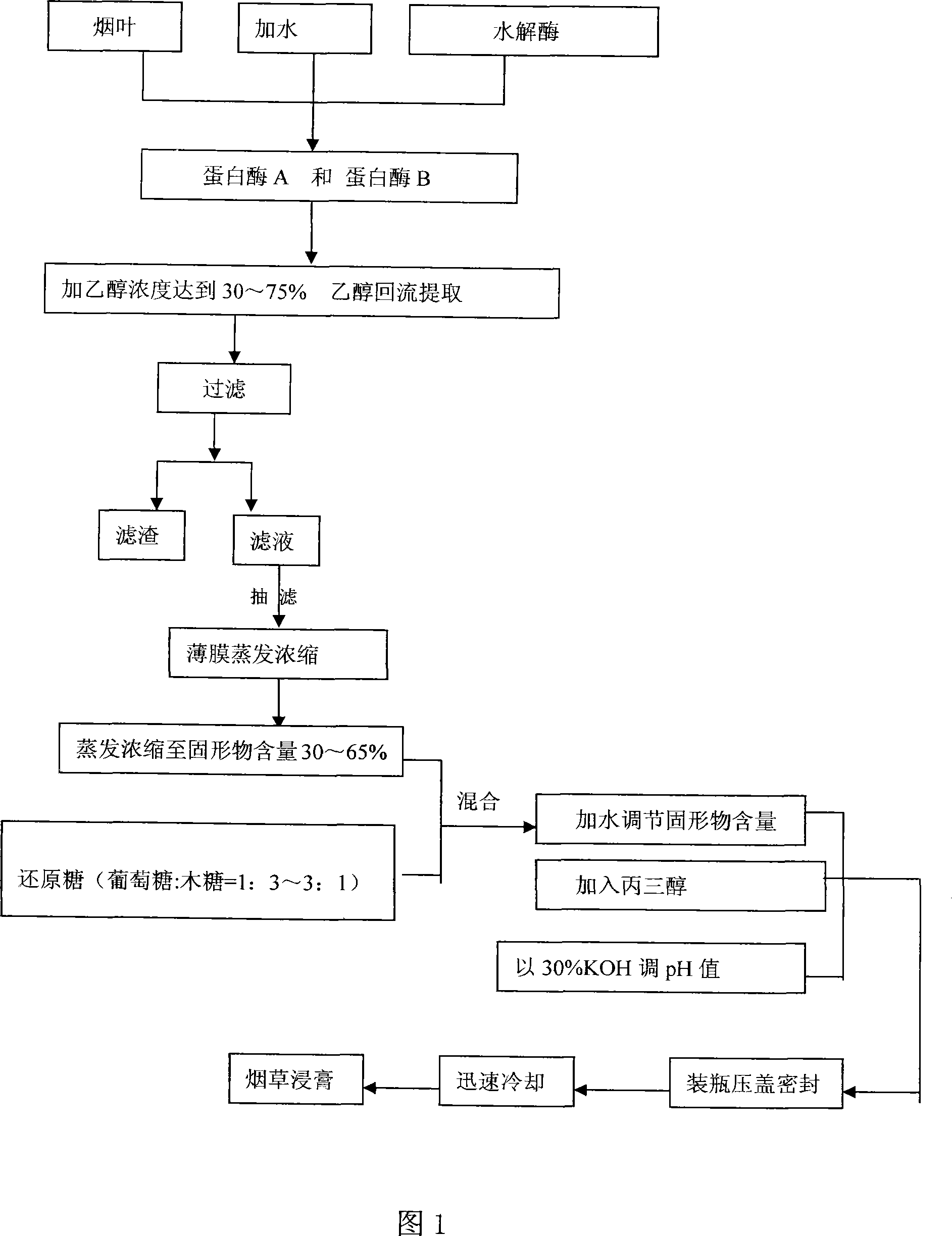

[0026] Referring to Fig. 1, (1) first add water and enzymes to the tobacco powder for enzymolysis: the degree of crushing of tobacco leaves is 40 mesh, the ratio of material to water is 1:4, the enzyme used is cellulase, and the dosage is 2‰ of the quality of tobacco leaves, and the enzymolysis time 14hr, enzymatic hydrolysis temperature 40°C; then add trypsin and acid protease, the dosage is 2‰ of tobacco leaf mass, enzymolysis time 14hr, enzymolysis temperature 40°C.

[0027] (2) Ethanol extraction, filtration and concentration: add absolute ethanol to (1) until the ethanol concentration is 30%, condense the reflux extraction, the extraction time is 4hr, filter after extraction, and filter with a plate and frame filter press, the filtrate After another suction filtration, the insoluble impurities in the extract will be removed; the extract should be concentrated by a thin-film evaporator that can be fed continuously. The evaporation conditions are condensing temperature 10°C ...

Embodiment 2

[0030] Referring to Fig. 1, (1) first add water and enzymes to the tobacco powder for enzymolysis: the degree of crushing of tobacco leaves is 200 mesh, the ratio of material to water is 1:15, the enzyme used is arabinase, and the dosage is 8‰ of the quality of tobacco leaves. The enzymolysis time is 6 hours, the enzymatic hydrolysis temperature is 70°C; then compound protease and trypsin are added, the dosage is 8‰ of the tobacco leaf mass, the enzymolysis time is 6hr, and the enzymolysis temperature is 70°C.

[0031] (2) Ethanol extraction, filtration and concentration: add absolute ethanol to the (1) enzymolysis solution until the ethanol concentration is 75%, reflux extraction in the condenser tube, the extraction time is 1hr, filter after extraction, and the filtrate is suction filtered again, The insoluble impurities in the extract are removed; the extract is concentrated by a thin-film evaporator that can be continuously fed, and the evaporation conditions are a condensa...

Embodiment 3

[0034] Referring to Fig. 1, (1) first add water and enzymes to the tobacco powder for enzymolysis: the degree of crushing of tobacco leaves is 80 mesh, the ratio of material to water is 1:7, the enzyme used is hemicellulase, and the dosage is 4‰ of the quality of tobacco leaves. The enzymolysis time is 12 hours, the enzymatic hydrolysis temperature is 60°C; then alkaline protease and neutral protease are added, the dosages are respectively 4‰ and 5‰ of the mass of tobacco leaves, the enzymolysis time is 10hr, and the enzymolysis temperature is 55°C.

[0035] (2) Ethanol extraction, filtration and concentration: add dehydrated ethanol to (1) until the ethanol concentration is 50%, reflux the condenser tube for extraction, the extraction time is 2hr, filter after extraction, and the filtrate is filtered once again, and the extract The insoluble impurities in the medium are removed; the extract is concentrated by a thin-film evaporator that can be continuously fed, and the evapora...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com