Polarization insensitivity liquid crystal photon crystal filter and making method thereof

A polarization-insensitive, photonic crystal technology, applied in instruments, optics, nonlinear optics, etc., can solve problems such as reducing the use range of liquid crystal photonic crystal filters, reducing signal energy, and affecting transmission distances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

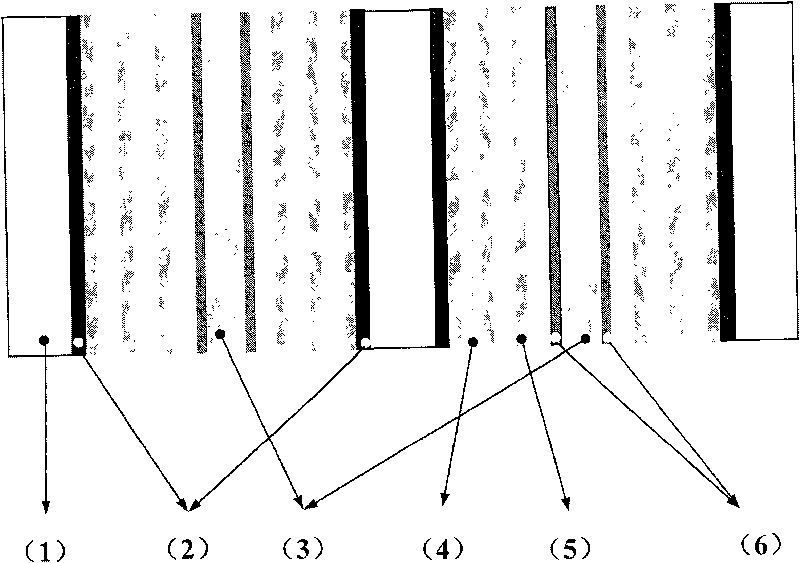

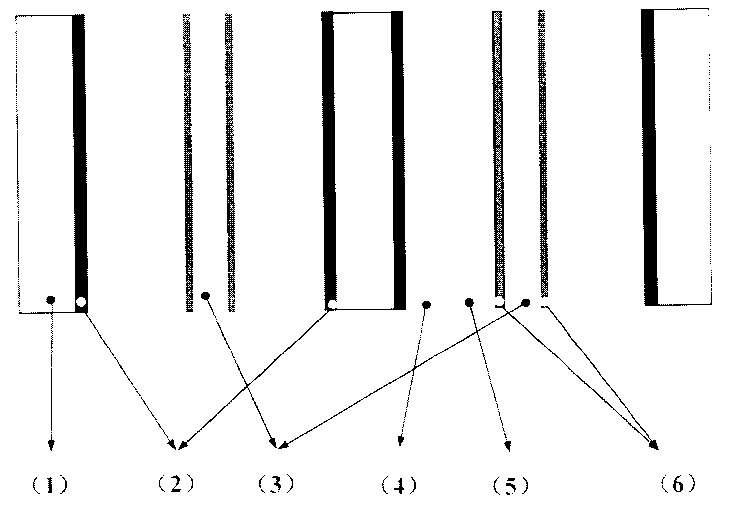

Image

Examples

Embodiment Construction

[0016] (1) Choose three clean and transparent glass substrates with a thickness of 1.1 mm, a flatness better than 1 / 10 of the wavelength, and an area of 1 cm x 1 cm. On both sides of one of them and on one side of the other two, oxidized Indium tin (ITO) electrode film;

[0017] (2) Use the H447700-7 box-type coating machine to alternately plate silicon dioxide and titanium dioxide films with a thickness of 265 nm and 165 nm on the ITO side of the three substrates, and plate 5 pairs in total;

[0018] (3) Print 110 nanometers of SE-410 type polyimide (PI) film on one side of the multilayer film of the tripolar plate, treat it at 80 degrees for 10 minutes at a curing temperature, and then treat it at 180 degrees for 30 minutes . After heat treatment, the PI film side of the substrate is subjected to directional rubbing treatment on a rubbing machine with flannelette;

[0019] (4) Spray spacers with a diameter of 500 nanometers on the PI film side of the three substrates;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com