Ultrathin glass cleaning carrying robot

A technology for handling robots and ultra-thin glass. It is applied in the directions of manipulators, conveyor objects, transportation and packaging, etc. It can solve the problems of not meeting the production cycle requirements of ultra-thin glass, low production efficiency of thick glass handling equipment, and high glass fragmentation rate. Achieve the effect of fast production tempo, easy high-speed movement and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

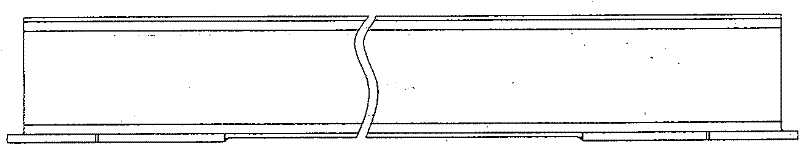

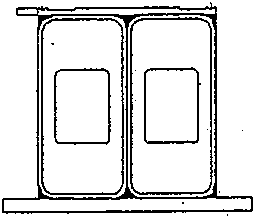

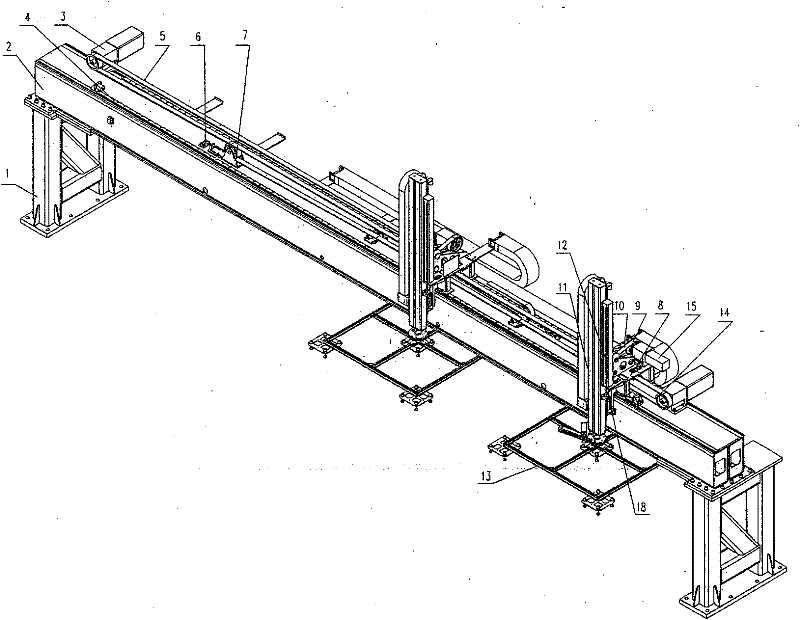

[0022] Such as figure 2 As shown, the present invention adopts two groups of frame-type columns 1 structures as the fixing and support of the whole equipment, and the span between the two groups of frame-type columns 1 is 8.8 meters. Both ends of the beam assembly 2 are respectively connected with two sets of frame columns 1 by means of bolt connection. The beam assembly 2 is welded by two rectangular square steel pipes, and reinforced by welding steel plates on the upper and lower surfaces of the rectangular square steel pipes. An X guide rail 4 is installed on the beam assembly 2, and a support 8 is installed on the X guide rail 4. The support 8 is a welded frame structure, and the X guide rail 4 is slidably connected with the support 8. One end of the X synchronous toothed belt 5 is connected to one end of the mounting plate of the bracket 8, and the other end of the X synchronous toothed belt 5 bypasses the driving synchronous belt pulley 14 and the driven synchronous bel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com