Method for removing oxysulfide and/or nitrogen oxide from flue gas and hydrocarbon oil cracking method

A catalytic cracking, inorganic oxide technology, applied in chemical instruments and methods, catalytic cracking, hydrocarbon oil cracking, etc., can solve the problems of only discarding, short effective period of adsorbent, single use of adsorbent, etc. The effect of reducing production cost and simplifying production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

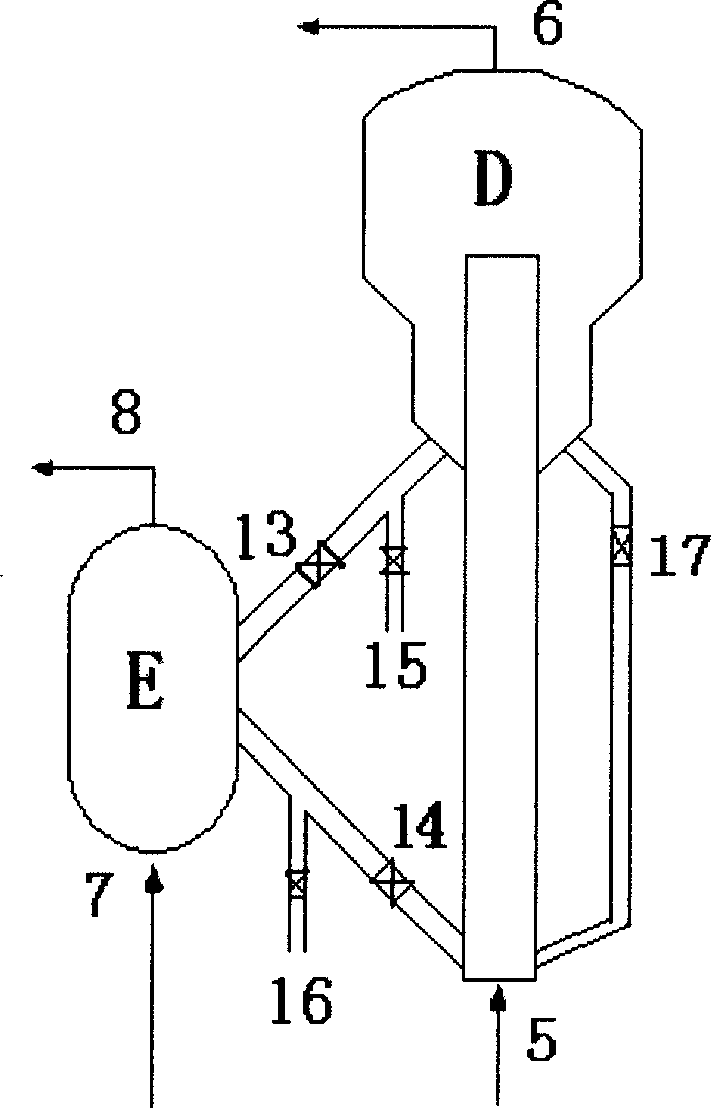

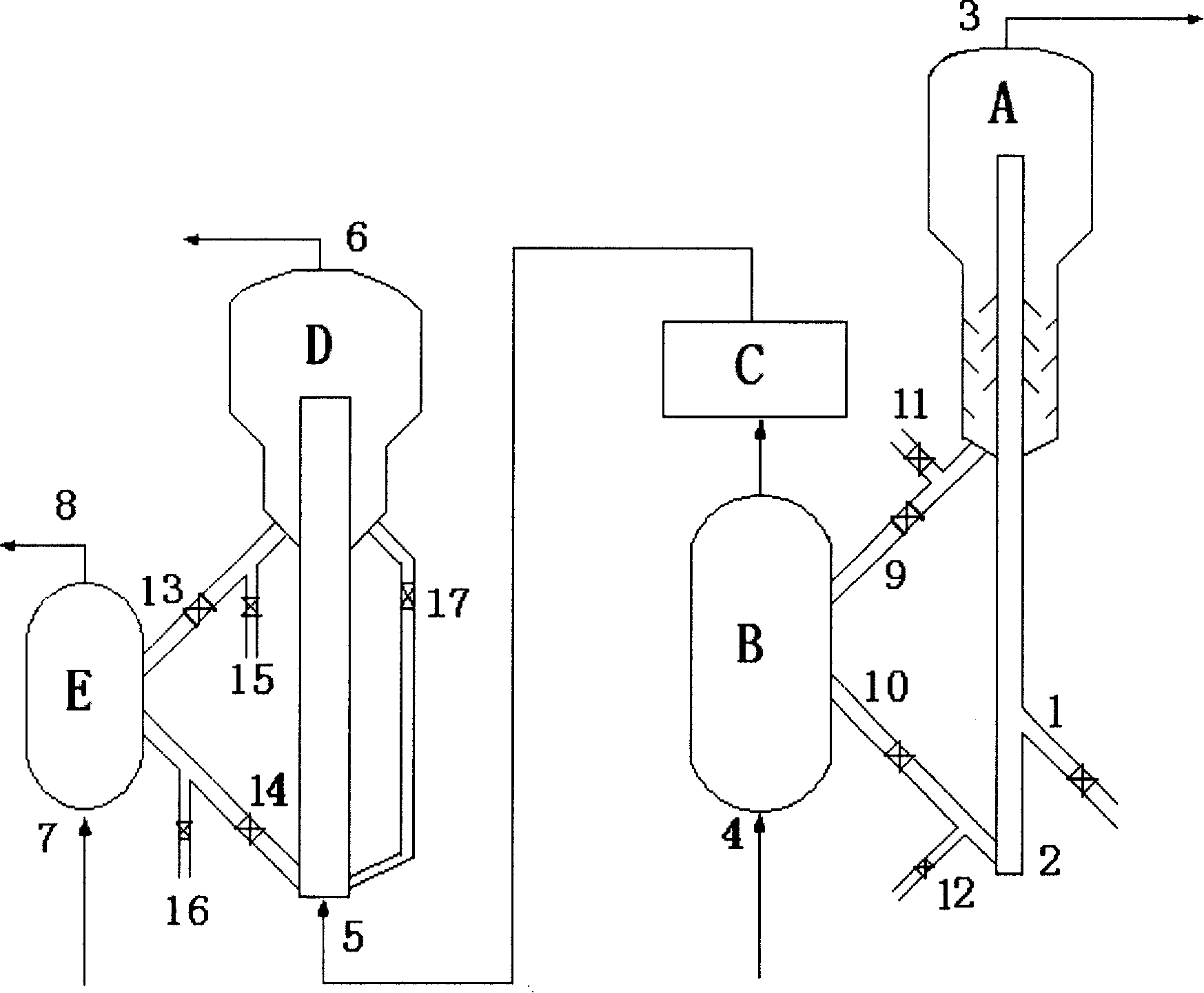

[0062] This example illustrates the method provided by the present invention for removing sulfur oxides and nitrogen oxides in the flue gas from catalytic cracking catalyst regeneration.

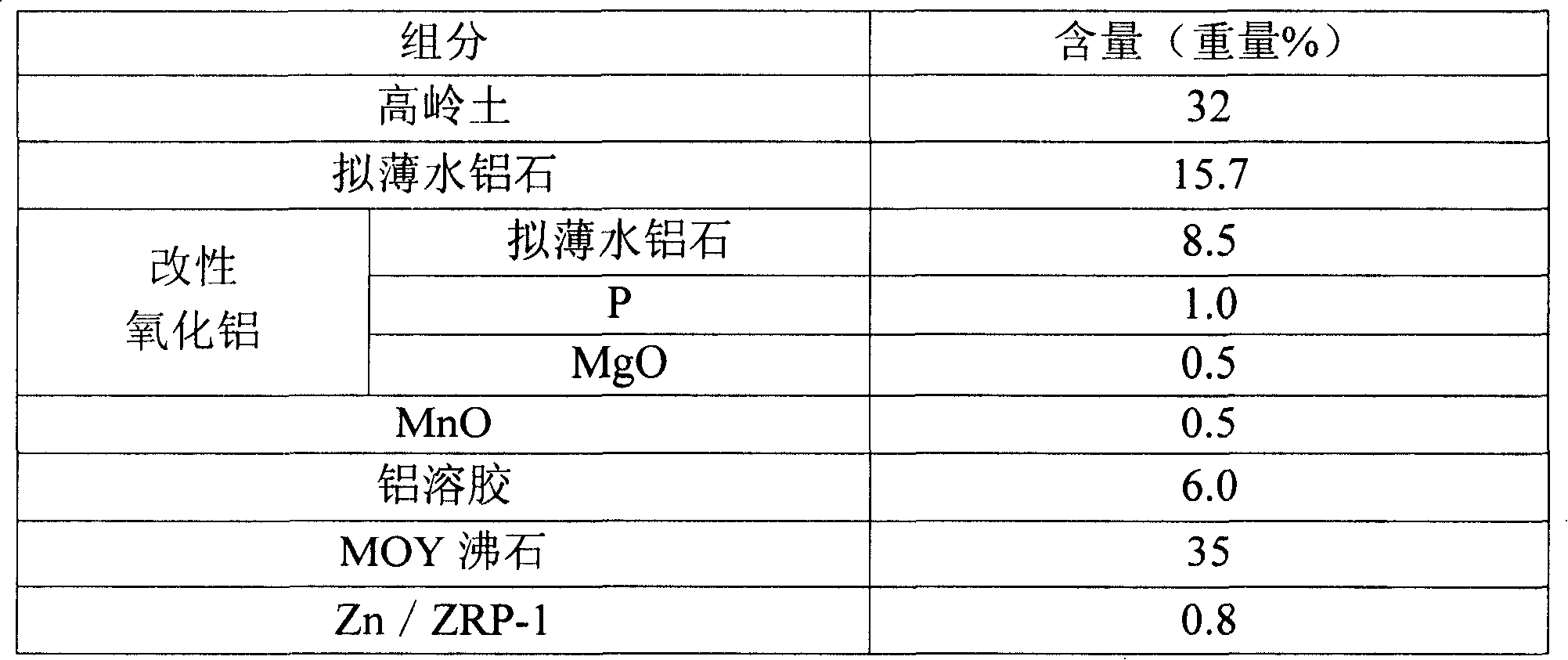

[0063] (1) Adsorption effect test of adsorbent

[0064] Pass the simulated flue gas into a fixed fluidized bed reactor (60 cm in diameter, 6 cm in thickness, and 3,700 cm in height) equipped with adsorbent, at a temperature of 215-225°C, and a weight hourly space velocity of 20,000-23,000 hours-1 , under the condition that the pressure in the fixed fluidized bed reactor is 0.008-0.015 MPa, the simulated flue gas is contacted with the adsorbent, and the gas product after contacting with the adsorbent is measured by the KM9106 comprehensive flue gas analyzer of Kane Company in the UK composition. The adsorbent is CR022 fresh industrial catalyst (industrial production of the Catalyst Factory of Qilu Petrochemical Company, the composition of the catalyst is shown in Table 2). The calculated de...

Embodiment 2-7

[0096] This example illustrates the method provided by the present invention for removing sulfur oxides and nitrogen oxides in the flue gas from catalytic cracking catalyst regeneration.

[0097] According to the method of step (1) in embodiment 1, remove the sulfur oxide and nitrogen oxide in the simulated flue gas of embodiment 1, and measure the present invention to remove sulfur oxide according to the method for step (3) in embodiment 1 And the NOx method lasts for an effective time. The difference is the type of FCC catalyst used as adsorbent, packing density, contact temperature of adsorption reaction, weight hourly space velocity and contact pressure, as shown in Table 8. Wherein, the main component content and physical and chemical properties of the MMC-3 (Qilu Petrochemical Company Catalyst Factory production) and GOR-III (Qilu Petrochemical Company Catalyst Factory production) used are shown in Table 7; 1.1% by weight, the carbon content of the regenerated catalyst ...

Embodiment 8-17

[0119] (1) The catalytic cracking catalyst is used as an adsorbent.

[0120] According to the method in Example 1, the sulfur oxides and nitrogen oxides in the simulated flue gas of Example 1 are continuously removed until the desulfurization rate drops to 80%. The difference is that the catalytic cracking catalyst used as the adsorbent is fresh MLC-500 Catalyst (Qilu Catalyst Factory production), obtains the fresh MLC-500 catalyst that has been used as adsorbent, hereinafter referred to as unregenerated adsorbent; With the regenerated MLC-500 catalyst that contains carbon deposition 0.043% through the catalytic cracking regeneration process, continue to remove Remove the sulfur oxides and nitrogen oxides in the simulated flue gas of Example 1 until the desulfurization rate drops to 80%, and obtain a regenerated catalyst with unregenerated adsorption performance after contacting with the regenerated flue gas of the catalytic cracking catalyst, hereinafter referred to as the reg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com