Hydrocracking method for more producing chemical industry light oil from poor heavy raw material

A heavy raw material, hydrocracking technology, applied in the field of hydrocarbon oil cracking, can solve the problem of low yield of chemical light oil, and achieve the effect of high cetane number, excellent quality and low impurity content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

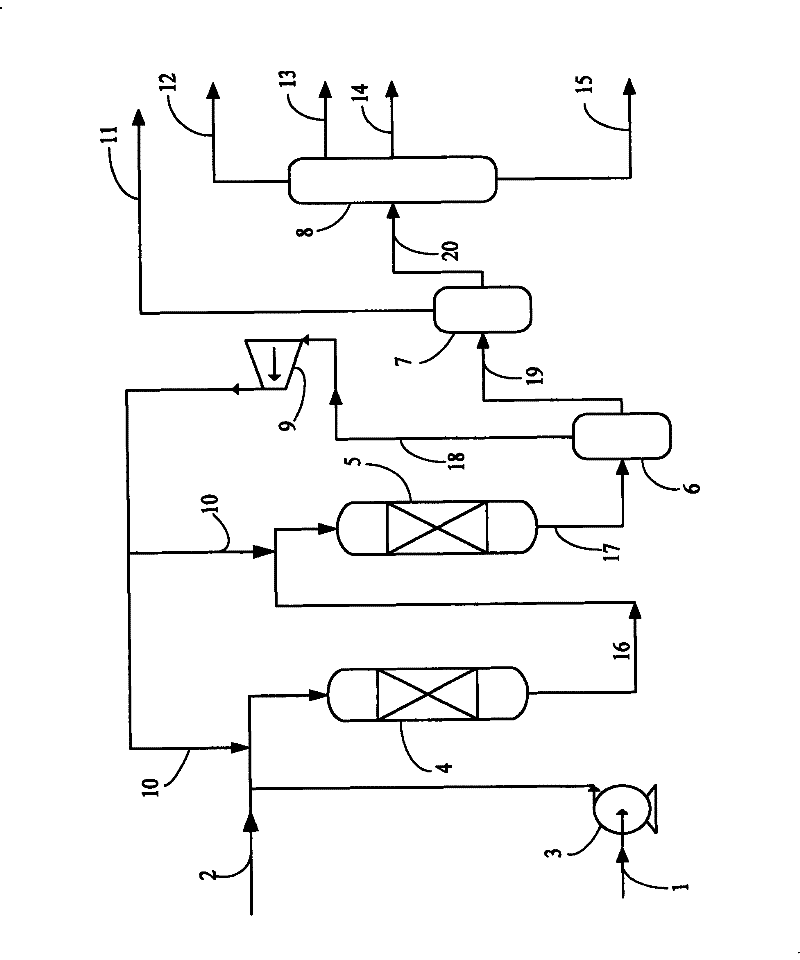

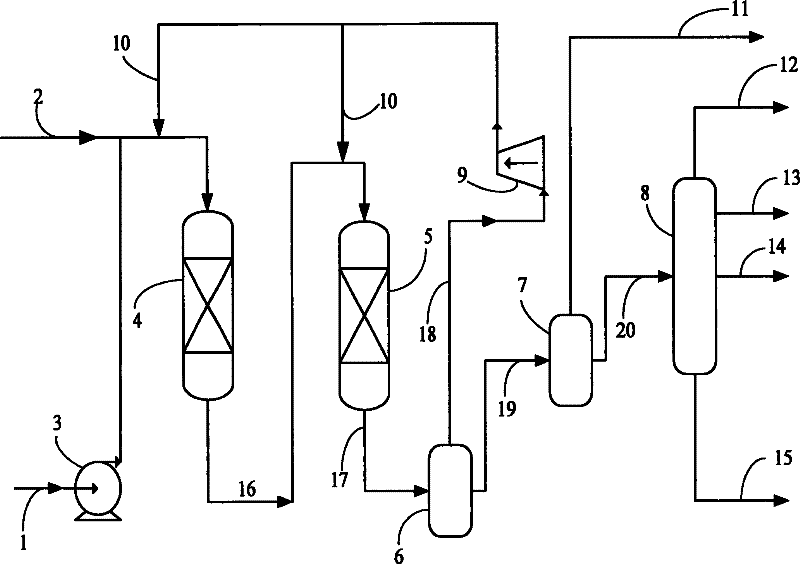

Image

Examples

Embodiment 1

[0040] This example uses the same raw material oil as in Comparative Example 1. After the raw material oil A is mixed with hydrogen, it is successively contacted with the hydrofinishing catalyst RN-32 and the hydrocracking catalyst RHC-5 to react without intermediate separation, and the effluent after the reaction Cooling and separation, the resulting hydrogen-rich gas is recycled, and the resulting liquid is fractionated to obtain light naphtha fractions, heavy naphtha fractions, diesel fractions and tail oil fractions, the hydrogenation catalyst RN-32 and the hydrocracking catalyst RHC-5 The loading volume ratio is 6:4, the reaction conditions are shown in Table 2, and the yield and main properties of the obtained product are shown in Table 3.

[0041] It can be seen from the data in Table 2 and Table 3 that, compared with Comparative Example 1, under the conditions of 10°C lower hydrofining reaction temperature and 8°C lower hydrocracking reaction temperature, the yield of h...

Embodiment 2

[0043] A mixed oil of VGO and CGO is used as the raw material oil B, and its raw material properties are shown in Table 4. It can be seen from Table 4 that the raw material oil quality is poor, the nitrogen content reaches 2300μg / g, and the dry point exceeds 550°C, which is a kind of raw material that is difficult to process.

[0044] After the raw material oil B is mixed with hydrogen, it is sequentially contacted with the hydrofinishing catalyst RN-32 and the hydrocracking catalyst RHC-5 without intermediate separation. The effluent after the reaction is cooled and separated, and the hydrogen-rich gas obtained is recycled. The obtained liquid Light naphtha fractions, heavy naphtha fractions, diesel fractions and tail oil fractions are obtained by fractional distillation. The upper part of the hydrorefining catalyst is filled with a protective agent, and the bottom of the hydrocracking catalyst is filled with a post-refining catalyst. The protective agent RG -1, the loading v...

PUM

| Property | Measurement | Unit |

|---|---|---|

| dry point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com