Rubber composition and use thereof

A technology of rubber composition and compound, which is applied in fuel cell parts, sealing/supporting devices, etc., can solve the problems of slow crosslinking speed and insufficient mechanical properties, and achieve excellent gas barrier properties and excellent compression set characteristics , excellent sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

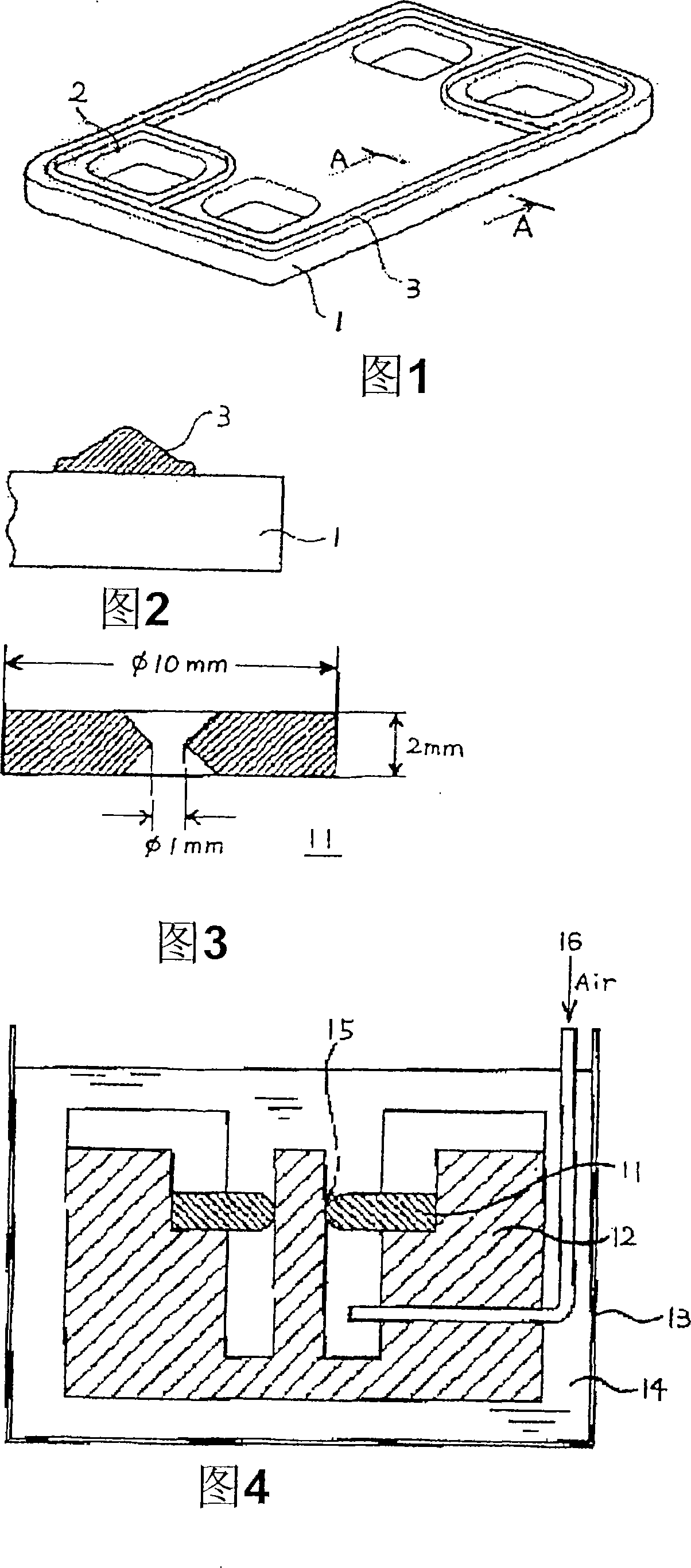

Image

Examples

manufacture example 1

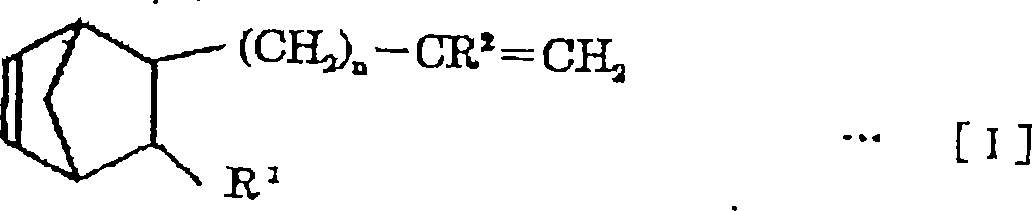

[0209] [Production of ethylene-propylene-5-vinyl-2-norbornene random copolymer [A-1]]

[0210] Terpolymerization of ethylene, propylene, and 5-vinyl-2-norbornene (hereinafter abbreviated as VNB) was continuously carried out using a stainless steel polymerizer with a stirring blade and an actual internal volume of 100 liters (stirring speed = 250 rpm). From the side of the polymerizer, at the rate of 60 liters of hexane per hour, 1.3 kg of ethylene, 2.5 kg of propylene, and 130 g of VNB, and 30 liters of hydrogen per hour, VO(OEt)Cl as a catalyst 2 23 mmol, Al(Et) 1.5 Cl 1.5 A rate of 161 mmoles was continuously supplied to the liquid phase. The copolymerization reaction was carried out under the conditions described above and in Table 1 to obtain an ethylene-propylene-VNB random copolymer [A-1] (hereinafter, simply referred to as copolymer [A-1]) in the state of a homogeneous solution. Then, a small amount of methanol was added to the polymerization solution continuously dr...

Embodiment 1

[0219] First, 100 parts by weight of the copolymer [A-1] shown in Table 1, 15 parts by weight of carbon black [produced by Asahi Carbon Co., Ltd., trade name F-200], talc [produced by Takehara Chemical Industry Co., Ltd., trade name Hi Micron (High Micron) HE-5] 20 parts by weight, and silica [produced by Ryusen Co., Ltd., trade name crystallite (Crystallite)] 20 parts by weight, with a planetary mixer with a capacity of 2 liters [manufactured by Inoue Co., Ltd. Produced, trade name: PLM-2 type] carry out kneading, obtain complex.

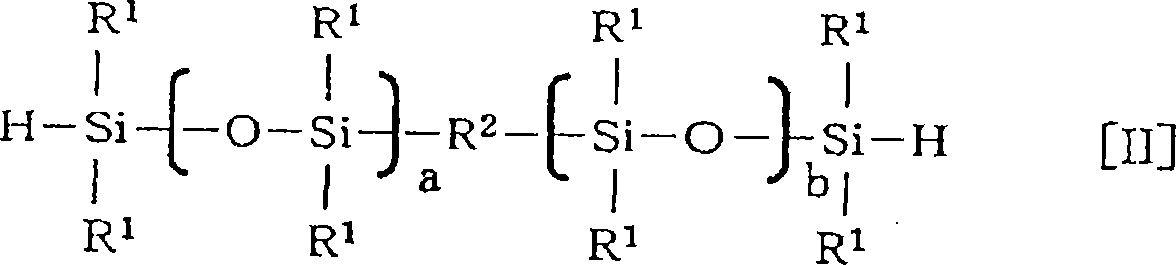

[0220] Then, 5 parts by weight of the above-mentioned SiH group-containing compound [C-1] (crosslinking agent), 0.1 part by weight of ethynylcyclohexanol as a reaction inhibitor, and platinum-1,3 were added to 160 parts by weight of the complex, 5,7-Tetravinylmethylcyclosiloxane complex [platinum concentration 0.5% by weight, terminal vinyl siloxane oil solution] 0.4 parts by weight, with 3 rollers of Φ3 inches [manufactured by Kodaira Co., Ltd. ,...

Embodiment 2~7

[0233] A sheet was obtained in the same manner as in Example 1, except that the above SiH group-containing compounds [C-2] to [C-7] were used instead of 5 parts by weight of the SiH group-containing compound [C-1] used in Example 1. Table 2 shows the SiH group-containing compound used and the amount thereof together with the evaluation results of these sheets.

PUM

| Property | Measurement | Unit |

|---|---|---|

| logarithmic viscosity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| iodine value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com