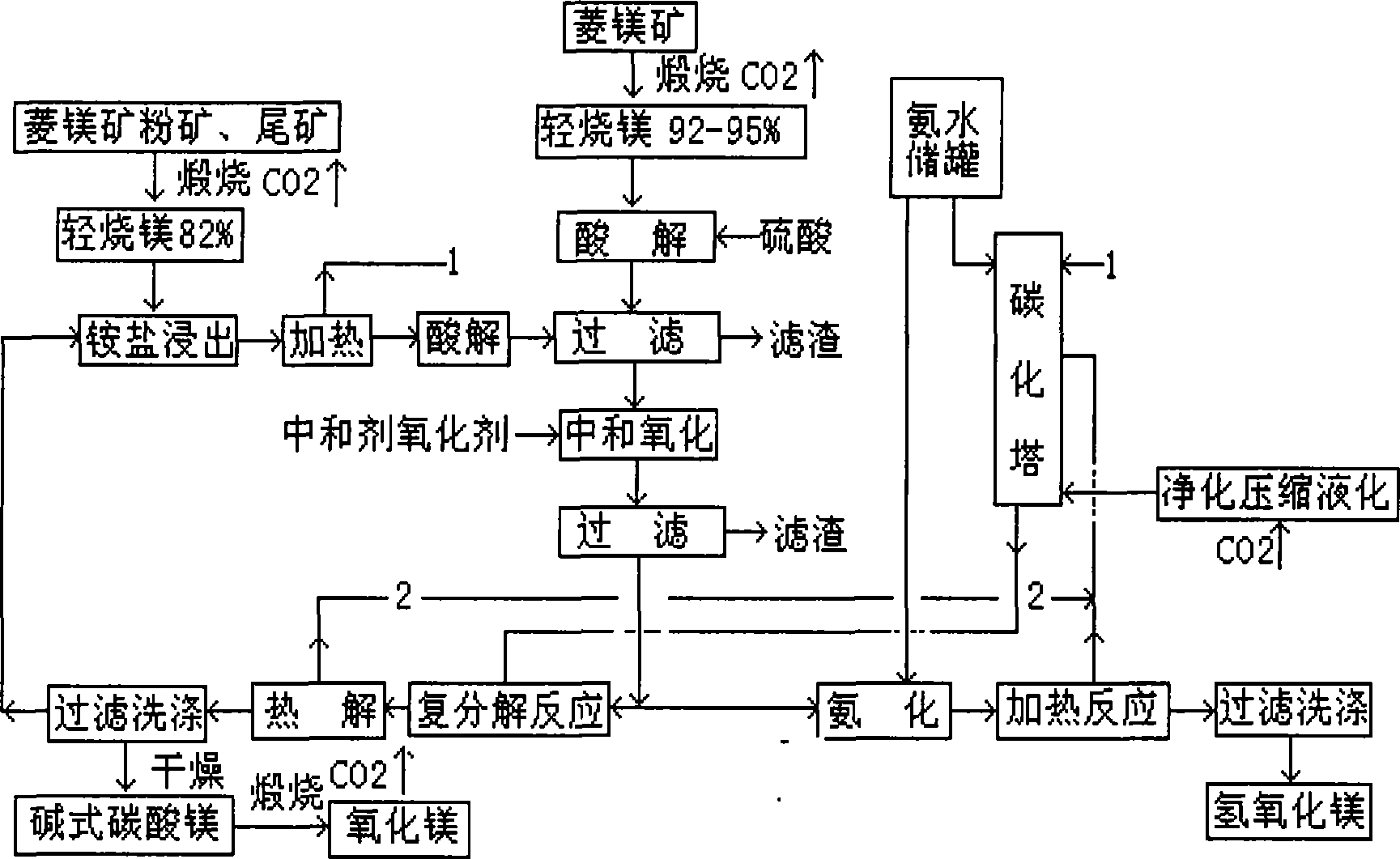

Method for producing series function magnesium chemical products by using magnesite

A chemical product, magnesite technology, applied in the direction of lime production, magnesium carbonate, magnesium sulfate, etc., can solve the problems of inconsistent and sustainable development, a large amount of smoke emission, high material consumption and energy consumption, and achieve broad adaptability, protection Environmental and production cost reduction effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0054] First take 50g of light-burned powder (magnesium oxide content greater than 90%), dissolve it with 100ml of water, add 60-120ml of concentrated sulfuric acid to dissolve, remove insoluble matter, and obtain crude magnesium sulfate solution 1.

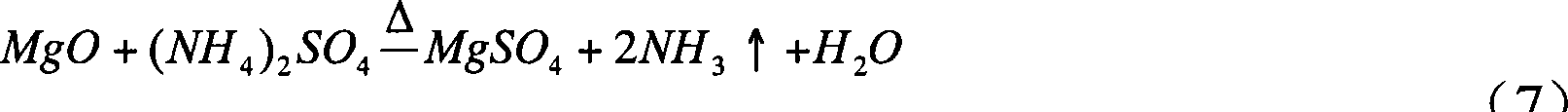

[0055]Then take 50g of lightly burned powder (magnesium oxide content greater than 80%), dissolve it with 100ml of ammonium sulfate, and react by heating at 90°C. The ammonia gas released is recycled and the crude magnesium sulfate solution 2 obtained by filtering. Add 10-20ml concentrated sulfuric acid to dissolve the insoluble matter and remove the insoluble matter to obtain a crude magnesium sulfate solution 3.

[0056] Mix the crude magnesium sulfate solution together, measure 200ml of the solution, heat it to 45~50℃, add 3~5g of MgO to the solution in multiple times to react, stir and react for 5 minutes, the solution will produce gray precipitate, filtered to get the filter residue as The mixture of magnesium borate and a small...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com