A layered polymer matrix PTC material and preparation method

A technology of polymers and matrix polymers, applied in the direction of conductive materials dispersed in non-conductive inorganic materials, plastic/resin/wax insulators, organic insulators, etc., can solve the problem that the shape structure is difficult to be designed, and it is difficult to obtain high PTC Intensity and other issues, to achieve the effect that is beneficial to the strength of PTC, the equipment is simple and easy to obtain, and the production cost is low

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

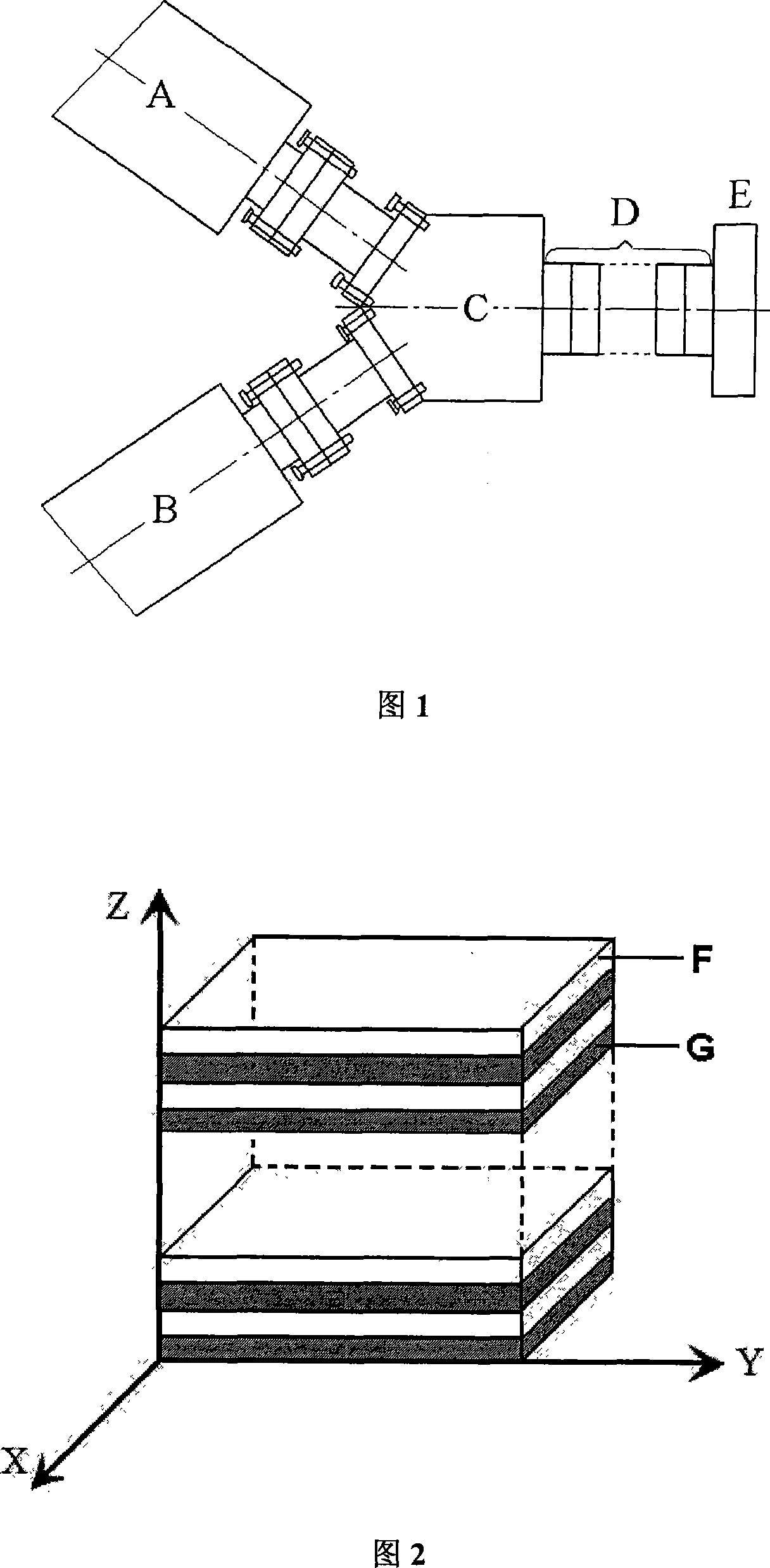

[0029] The raw materials are polypropylene and carbon black, the insulating layer and the conductive layer are pure polypropylene and carbon black filled polypropylene respectively. Firstly, ordinary carbon black-filled polypropylene was prepared, and the carbon black content was 11%. After the polypropylene and carbon black were dried, they were melt-mixed and granulated in a twin-screw extruder. The conductive layer and insulating layer pellets are put into the two extruders A and B of the layered co-extrusion device respectively, the speed ratio of the extruders is 2:1, and the temperature of each section of the extruder is controlled between 170-200°C. The temperatures of converging unit C, splitting unit D and outlet die E are all about 200°C. Using one splitting unit, the PTC material product melt flows out of the exit die under the traction of the traction device, and after being cooled by the cooling device, that is A 4-layer layered polypropylene-based PTC material wa...

Embodiment 2

[0031]The raw materials are polypropylene and carbon black, the insulating layer and the conductive layer are pure polypropylene and carbon black filled polypropylene respectively. Firstly, ordinary carbon black-filled polypropylene was prepared with a carbon black content of 8.5%. After the polypropylene and carbon black were dried, they were melt-mixed and granulated in a twin-screw extruder. The conductive layer and the insulating layer pellets are respectively put into two extruders A and B of the layered co-extrusion device, the speed ratio of the extruders is 1:1, and the temperature of each section of the extruder is controlled between 170-200°C. The temperatures of converging unit C, splitting unit D and outlet die E are all about 200°C. Using two splitting units, the PTC material product melt flows out of the exit die under the traction of the traction device, and after being cooled by the cooling device, that is An 8-layer layered polypropylene-based PTC material was...

Embodiment 3

[0033] The raw materials are polypropylene and carbon black, the insulating layer and the conductive layer are pure polypropylene and carbon black filled polypropylene respectively. First, ordinary carbon black-filled polypropylene was prepared, with a carbon black content of 5.2%. After the polypropylene and carbon black were dried, they were melt-mixed and granulated in a twin-screw extruder. The conductive layer and the insulating layer pellets are respectively put into two extruders A and B of the layered co-extrusion device, the speed ratio of the extruders is 1:1, and the temperature of each section of the extruder is controlled between 170-200°C. The temperatures of converging unit C, splitting unit D and outlet die E are all about 200°C. Using one splitting unit, the PTC material product melt flows out of the exit die under the traction of the traction device, and after being cooled by the cooling device, that is A two-layer layered polypropylene-based PTC material was...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com