Fibre reinforcing zinc aluminum phosphate based composite material and method for manufacturing the same

A fiber-reinforced material, zinc-aluminum phosphate technology, applied in the manufacture of tools, ceramic molding machines, etc., to achieve the effect of easy access to raw materials, high heat resistance stability, and high performance/price ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

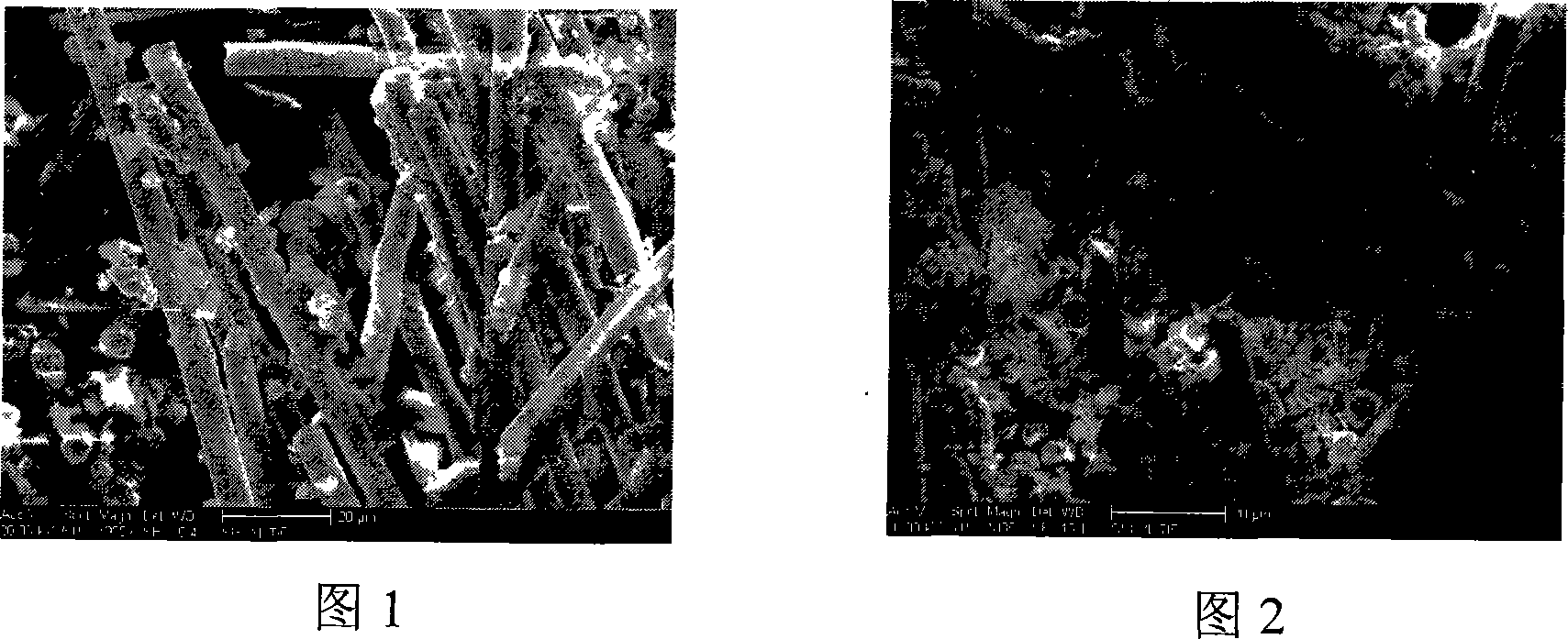

Image

Examples

specific Embodiment approach 1

[0014] Embodiment 1: In this embodiment, the fiber-reinforced zinc-aluminum phosphate-based composite material is mainly made of fiber-reinforced materials and zinc-aluminum phosphate cementitious materials through compression molding; wherein the fiber-reinforced materials are heat-treated.

[0015] The fiber-reinforced zinc-aluminum phosphate-based composite material of the present invention has a compact structure, excellent performance, and good heat resistance stability. The bending strength of the composite material at room temperature can reach 60MPa-140MPa, and the application range is wide.

[0016] In this embodiment, the fiber-reinforced material accounts for 30-75% of the weight of the fiber-reinforced zinc-aluminum phosphate-based composite material.

specific Embodiment approach 2

[0017] Embodiment 2: The difference between this embodiment and Embodiment 1 is that a protective coating is added on the surface of the fiber reinforced material. The protective coating is a silane coupling agent coating, an inorganic nanoparticle sol coating or a silicone resin coating. layer; the silane coupling agent is one of silane coupling agent KH-550, silane coupling agent KH-560, and silane coupling agent A-151; the inorganic nanoparticle sol is SiO 2 Sol, Al 2 o 3 Sol, TiO 2 One of the sols; the silicone resin is one of the methyl silicone resin and the phenyl silicone resin; the inorganic nanoparticle sol is prepared by a sol-gel method.

[0018] In this embodiment, the protective coating accounts for 0.05-2% of the weight of the fiber reinforced material. Described silane coupling agent is all commercially available products.

specific Embodiment approach 3

[0019] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that the fiber-reinforced material accounts for 40-60% of the weight of the fiber-reinforced zinc-aluminum phosphate-based composite material. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com