Synthesis of fluoridation aquosity polyurethane-polyacrylate composite emulsion

A polyacrylate and water-based polyurethane technology, which is applied in the synthesis of water-based polyurethane-polyacrylate composite emulsions, can solve the problems of poor gloss, poor water resistance of latex films, poor self-thickening properties, etc., and achieve the effect of improving surface performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

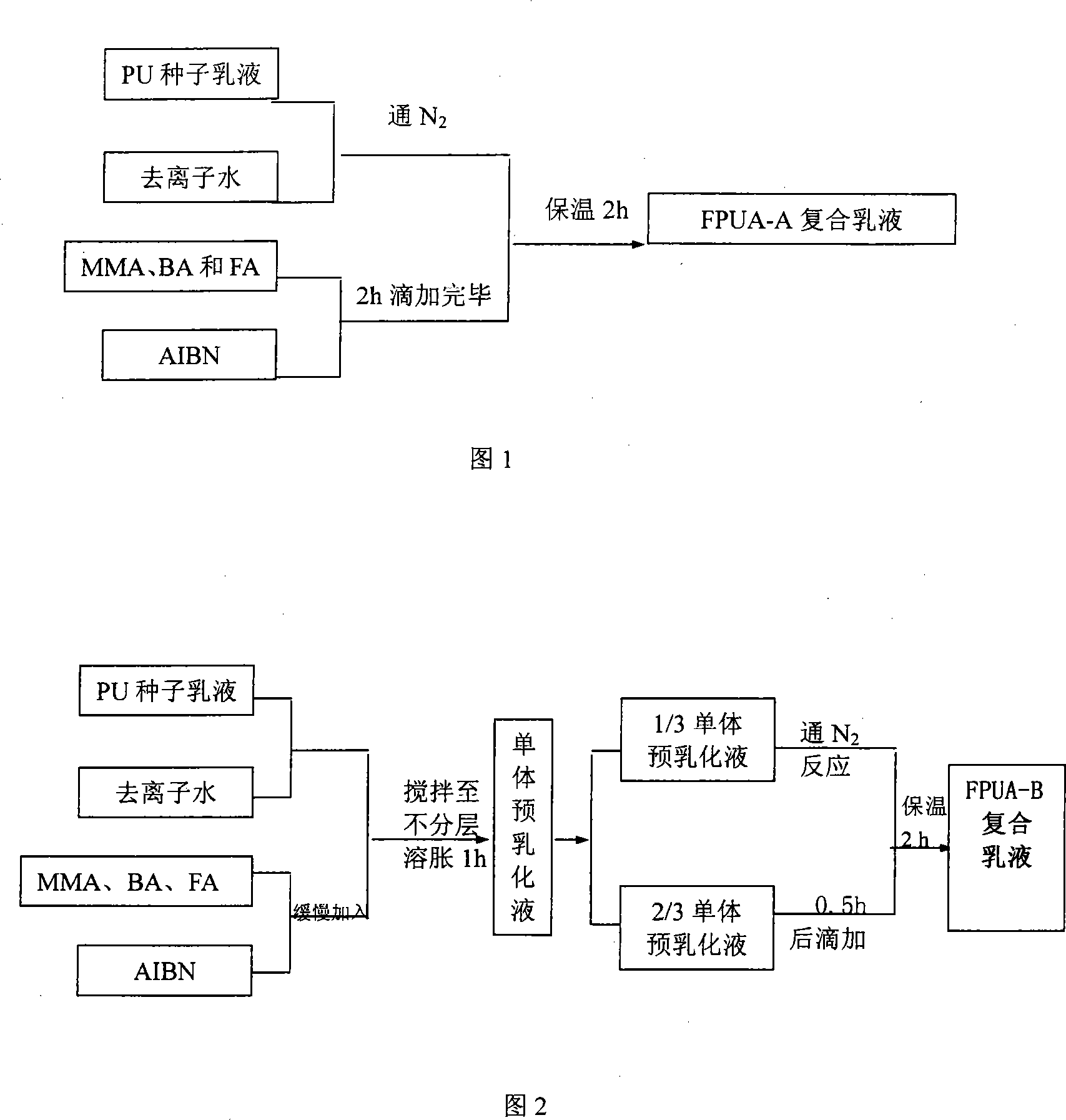

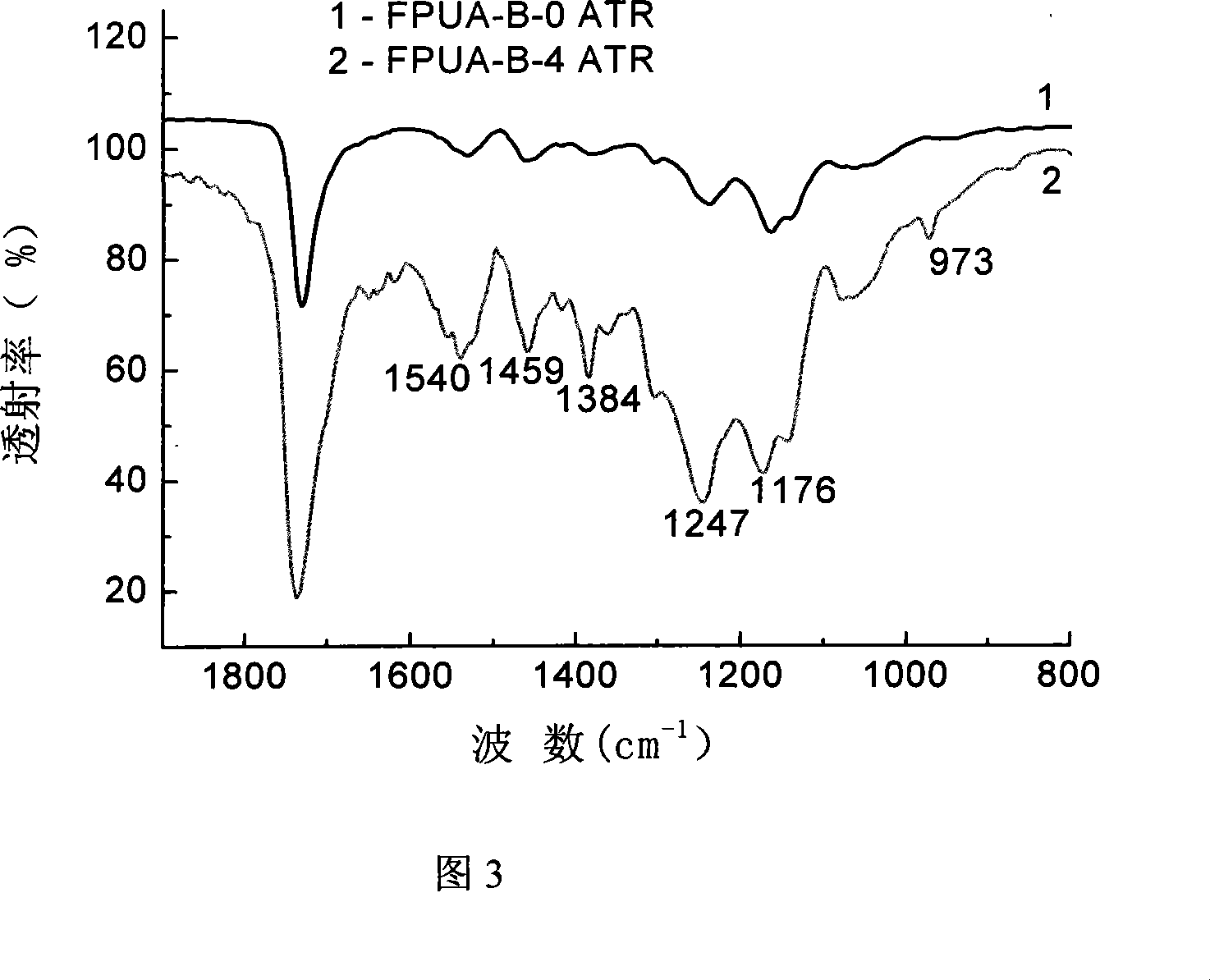

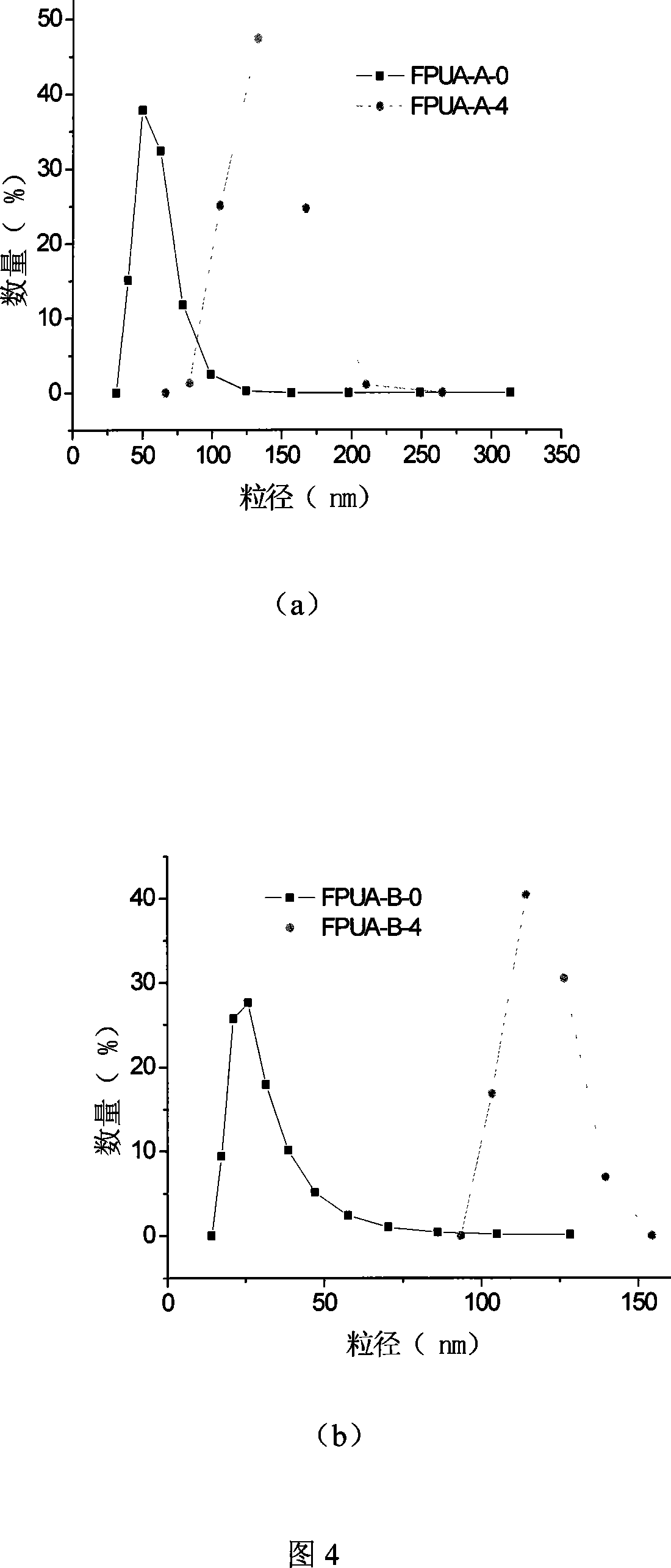

[0024] Synthesis method of fluorinated waterborne polyurethane-polyacrylate composite emulsion

[0025] 1. Main experimental raw materials

[0026] Isophorone diisocyanate (IPDI), industrial product, Bayer Company of Germany; Polyester diol, homemade in the laboratory; Dimethylol propionic acid (DMPA), industrial product, Sweden Perstorp company; Diethylene glycol (DEG), analytically pure, Shanghai Chemical Reagent Company; stannous octoate (T-9), reagent grade, Shanghai Chemical Reagent Company; triethylamine (TEA), chemically pure, Beijing Yili Fine Chemical Company; acetone (AT ), industrial product, Yanshan Petrochemical Company; methyl methacrylate (MMA), butyl acrylate (BA) are industrial products, Beijing Dongfang Chemical Plant; dodecafluoroheptyl methacrylate (FA), analytically pure, Harbin Xuejia Company; azobisisobutyronitrile (AIBN), reagent grade, Shanghai Bangcheng Chemical Co., Ltd.; ammonia water, industrial product; deionized water, self-made.

[0027] Two, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com