Plastic container having pearl-like appearance and process for producing the same

A technology for plastic containers and manufacturing methods, applied in the directions of containers, rigid containers, flexible coverings, etc., can solve the problems of inability to use, low productivity, and increased manufacturing costs, and achieves increased gloss, improved strength, and imparted surface smoothness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

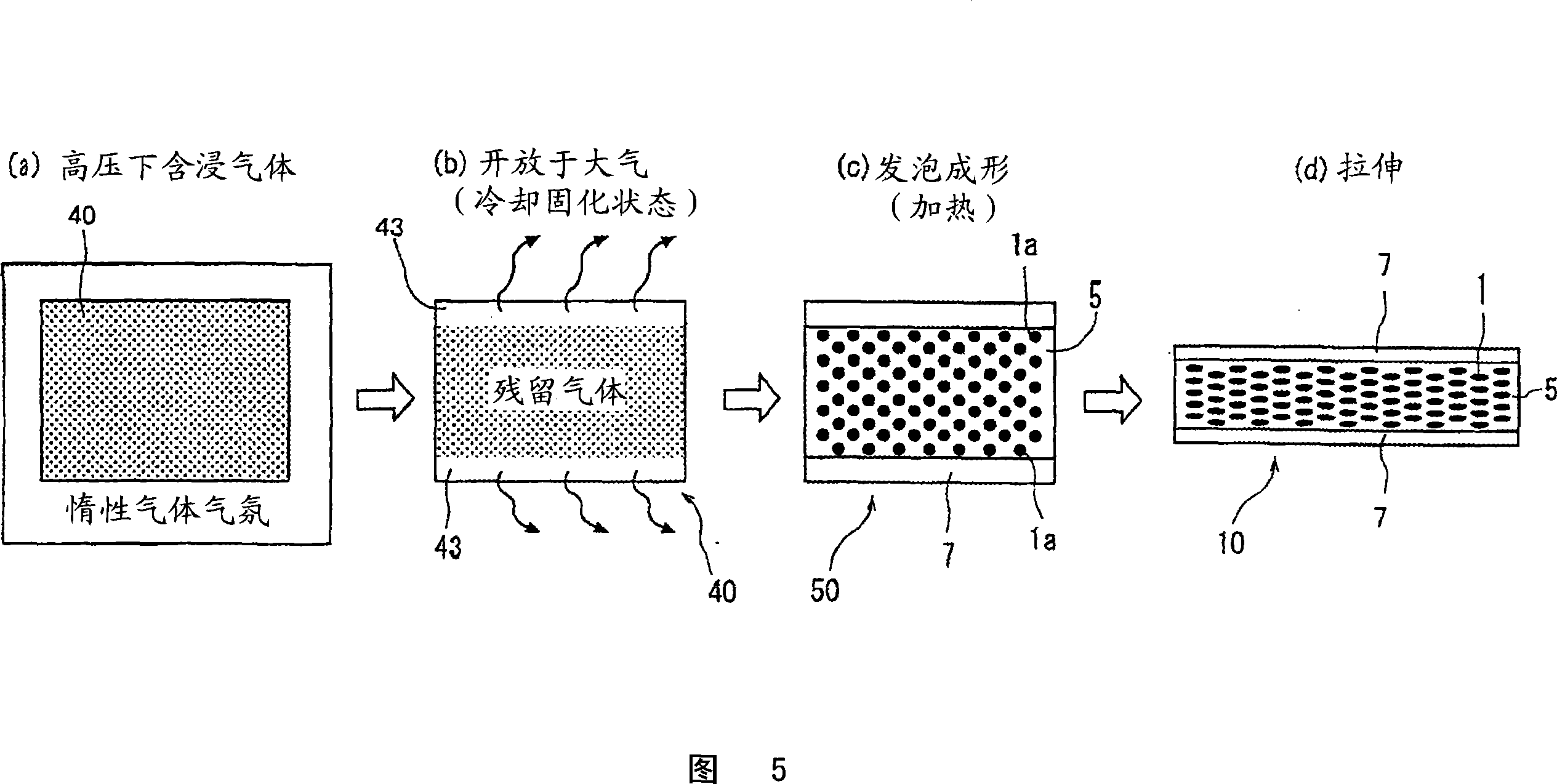

[0113] A non-foamed preform for a 500 ml bottle having a body wall thickness of 3 mm was produced by injection molding using homopoly PET (polyethylene terephthalate) having an intrinsic viscosity (IV) of 0.84 dL / g.

[0114] The preform was placed in a pressure-resistant container at 40° C., maintained at a pressure of 15 MPa for 1 hour, and impregnated with carbon dioxide gas. Then, the pressure was reduced to atmospheric pressure, and the preform was taken out from the pressure vessel, and kept under atmospheric pressure for 5 minutes. Further, spray hot water at 90° C. for 10 seconds on the outside of the preform to make it foam, and obtain a unit density of 8.5×10 7 unit / cm 3 , a foamed layer with a thickness of 180 μm, and a foamed preform having a skin layer with a thickness of 70 μm on its outer surface.

[0115] At this time, the cell density was calculated from the cross-sectional photograph using the following formula.

[0116] N f =(n / A) 3 / 2

[0117] N f : un...

Embodiment 2

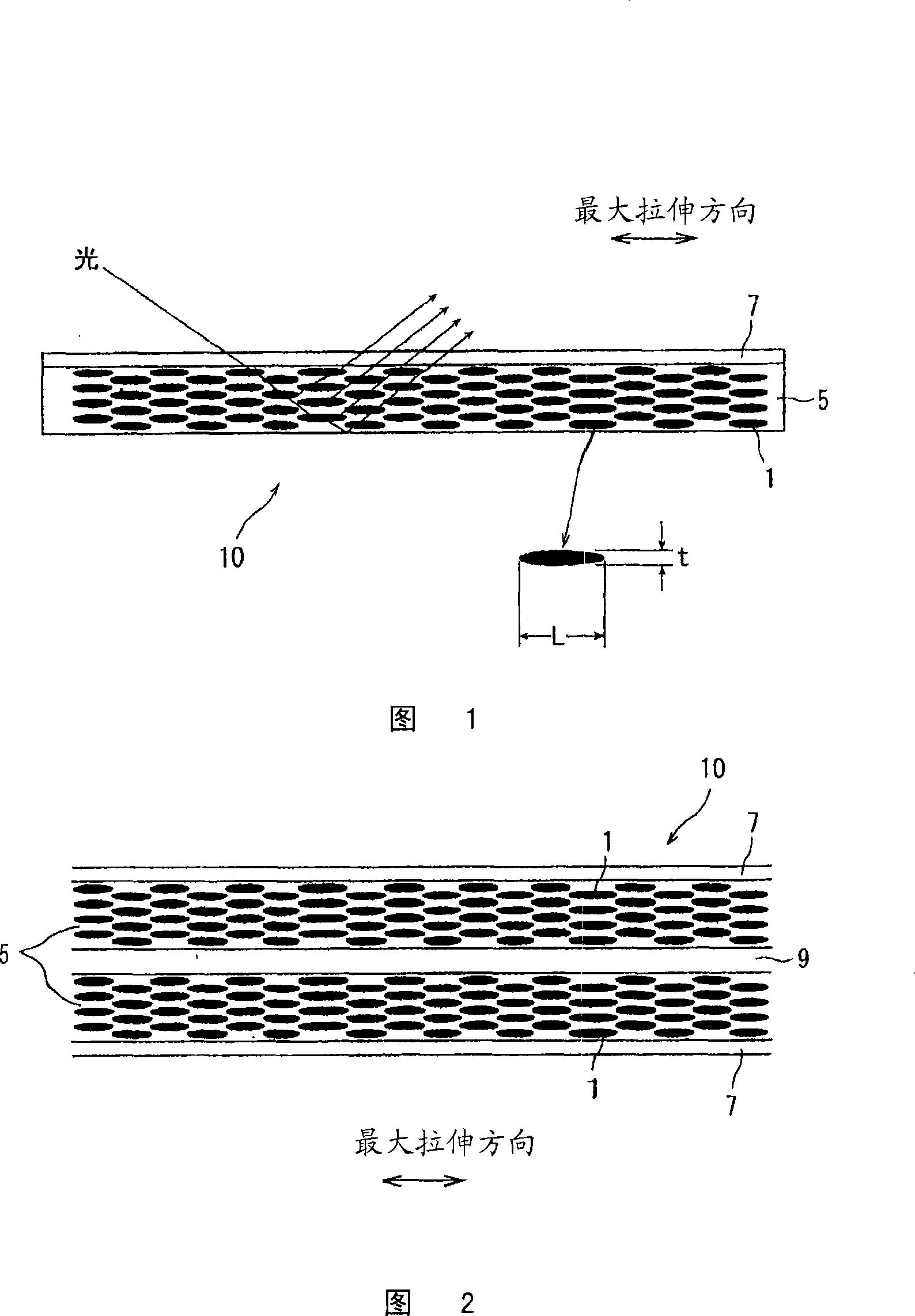

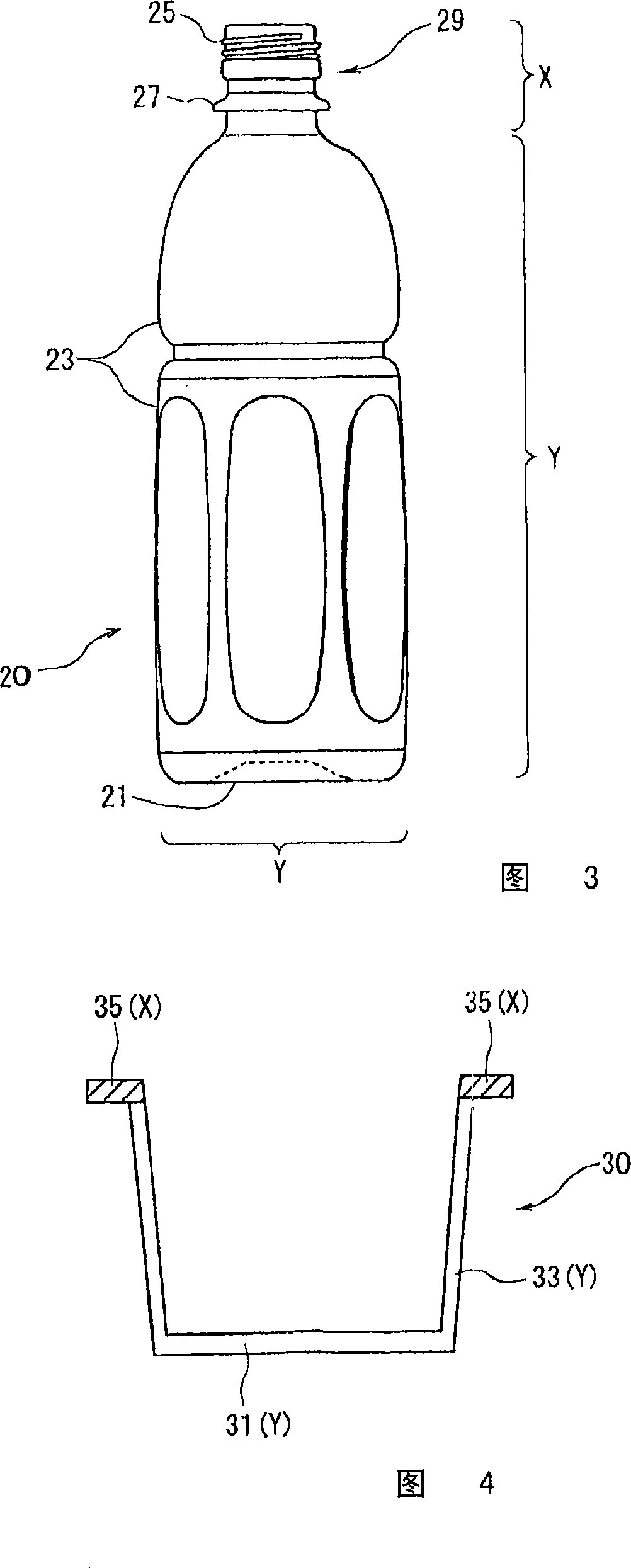

[0129] The foamed preform produced by the same method as in Example 1 was blow-molded into a bottle shape with a draw ratio equivalent to 3 times in length and 3 times in width, and the average wall thickness of the container in the side wall was 0.32 mm, The foamed PET bottle has an average surface roughness Ra of 0.3 μm, a skin layer thickness of 10 μm, an average long diameter of bubbles in the foam layer of 42 μm, an average aspect ratio of 11.6, and excellent appearance and pearl-like luster.

Embodiment 3

[0131] Using a copolymerized PET with an intrinsic viscosity (IV) of 0.90 dL / g containing 5 mol% of isophthalic acid, an average wall thickness of 0.58 mm and a cell density of 4×10 6 unit / cm 3 A foamed sheet with almost spherical cells. At this time, by properly controlling the temperature of the T-die, the surface of the sheet can be smoothed. The foamed sheet obtained as described above is stretched vertically 2 × horizontally 2 times with a biaxial stretching machine, it is heat-sealed, and when it is made into a bag-shaped container, the average wall thickness of the container is 0.16 mm, and the average surface roughness Ra was 4.3 μm, the average major diameter of the cells in the foam layer was 101 μm, the average aspect ratio of the cells was 8.4, and the bag had a smooth surface and good appearance and pearly luster.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average long diameter | aaaaa | aaaaa |

| Surface roughness | aaaaa | aaaaa |

| Average wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com