Natural plant material of processing cationic dye in industrial wastewater and method thereof

A cationic dye and wastewater treatment technology, which is applied in chemical instruments and methods, adsorption water/sewage treatment, and other chemical processes, can solve the problems of activated carbon restricting the widespread use of activated carbon, affecting the universal use of activated carbon, and difficult regeneration of activated carbon. High price, high cost, and the effect of saving regeneration costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] 1. Preparation of grapefruit peel particles:

[0033] Shred the pomelo peel, dry it in a constant temperature drying oven at 80°C to constant weight, then soak it in distilled water for 2 hours to remove dust and foreign matter, then take it out and dry it in a constant temperature drying oven at 80°C to constant weight, and use a grinder After crushing, sieve to obtain 40-60 mesh, 60-80 mesh, 80-100 mesh, 100-120 mesh and 120-140 mesh particles, which are stored in a dry place for later use.

[0034] 2. Cationic Dye Screening

[0035] Methylene blue referred to as MB, λ max =660nm; neutral red referred to as NR, λ max =520nm, all purchased from Shanghai Sanaisi Reagent Co., Ltd. Prepare a 200mg / l stock solution with distilled water, and dilute it according to the required concentration when used.

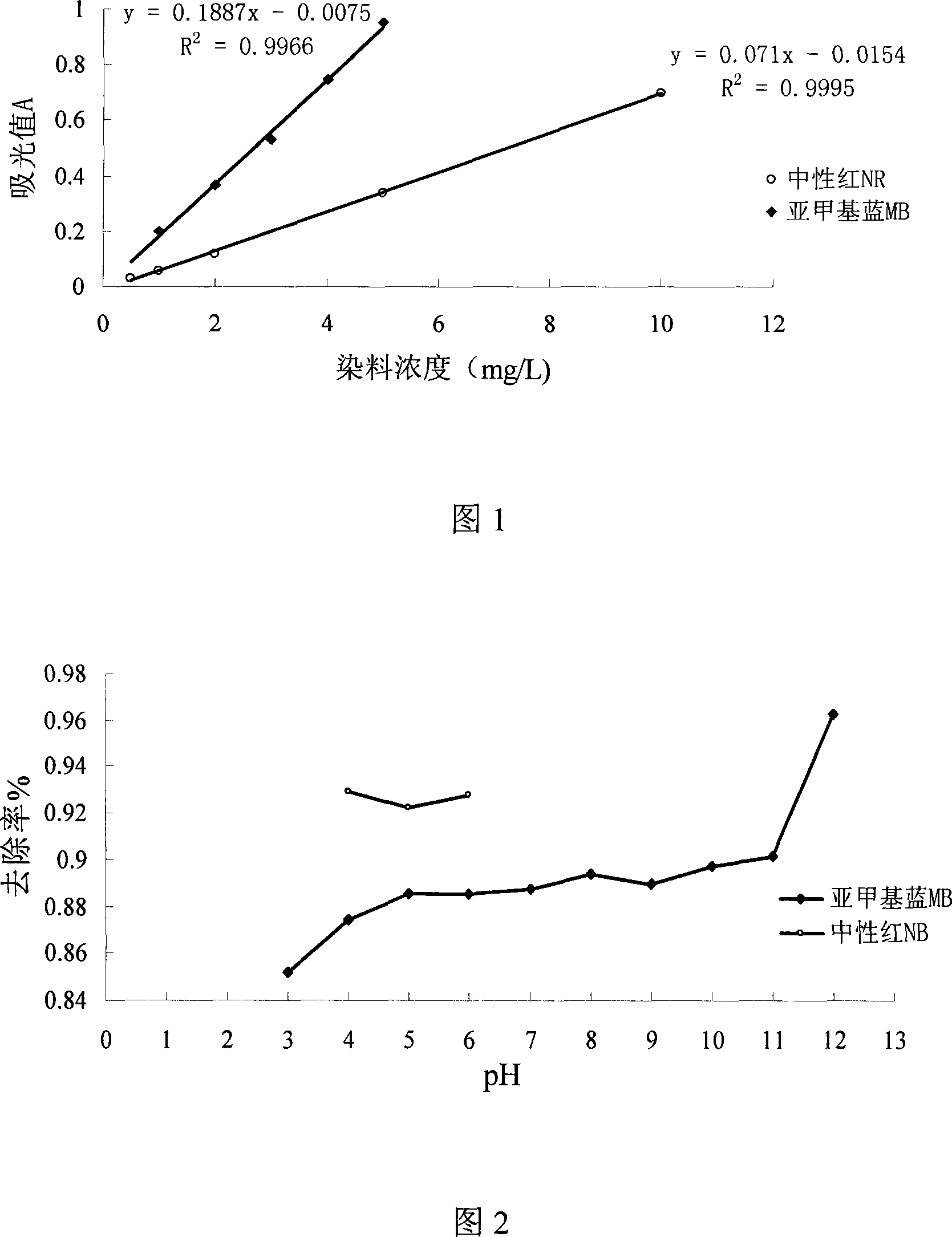

[0036] 2.1 Cationic dye standard curve

[0037] Take 1, 2, 3, 5, 6, 8, 10mg / l two kinds of dye solutions, measure the absorbance values at the respective maximum abso...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com