Method for restricting membrane pollution by using photocatalysis oxidation of nano material

A technology for photocatalytic oxidation and membrane inhibition, which is applied in the field of membrane fouling, can solve the problems of reduced water production, increased operating costs, and reduced membrane flux, and achieves the effects of extending service life, saving power consumption, and increasing membrane flux.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

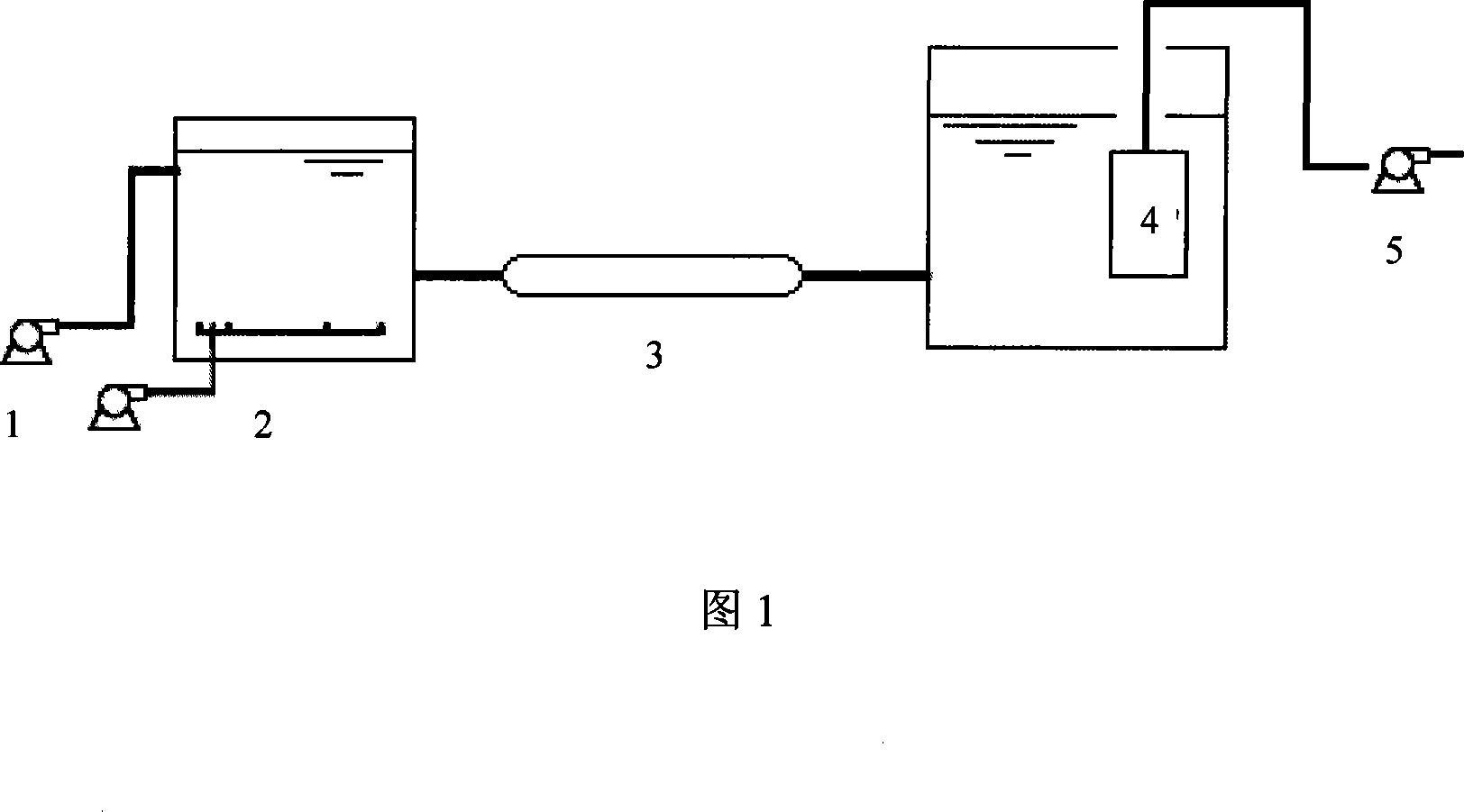

Image

Examples

Embodiment 1

[0026] Membrane bioreactor feed water is simulated biological sewage, and the water quality is as follows: COD concentration is 800mg / L, ammonia nitrogen concentration is 10mg / L, pH value is 6.5, dissolved oxygen concentration is 2.0-4.0mg / L, hydraulic retention time is 5h, Sludge residence time is 5d, nano TiO 2 The hydraulic retention time of the photocatalytic oxidation reactor is 2h. Experimental results: After 20 days of operation, the membrane flux is 15-20L / m 2 h. Compared with ordinary membrane bioreactors, the membrane flux is increased by more than 50%.

Embodiment 2

[0028] Membrane bioreactor feed water is simulated biological sewage, and the water quality is as follows: COD concentration is 500mg / L, ammonia nitrogen concentration is 30mg / L, pH value is 7.5, dissolved oxygen concentration is 3.0mg / L, hydraulic retention time is 8h, sludge The residence time is 8d, nano-TiO 2 The hydraulic retention time of the photocatalytic oxidation reactor is 3h. Experimental results: After 20 days of operation, the membrane flux is 15-20L / m 2 h. Compared with ordinary membrane bioreactors, the membrane flux is increased by more than 50%.

Embodiment 3

[0030] Membrane bioreactor feed water is simulated biological sewage, and the water quality is as follows: COD concentration is 500mg / L, ammonia nitrogen concentration is 60mg / L, pH value is 8.5, dissolved oxygen concentration is 4.0mg / L, hydraulic retention time is 10h, sludge The residence time is 10d, nano-TiO 2 The hydraulic retention time of the photocatalytic oxidation reactor is 5h. After running for 20 days, the membrane flux is 15-20L / m 2 h. Compared with ordinary membrane bioreactors, the membrane flux is increased by more than 50%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com