Soft soil, sludge impulse type electro-dewatering treating method and device thereof

A treatment method and pulsed technology, applied in dewatering/drying/concentrating sludge treatment, soil protection, construction, etc., can solve the problems of unsatisfactory effect, high treatment cost, high energy consumption, etc., to improve electroosmotic dehydration Efficiency, good ionization effect, and the effect of improving electroosmotic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

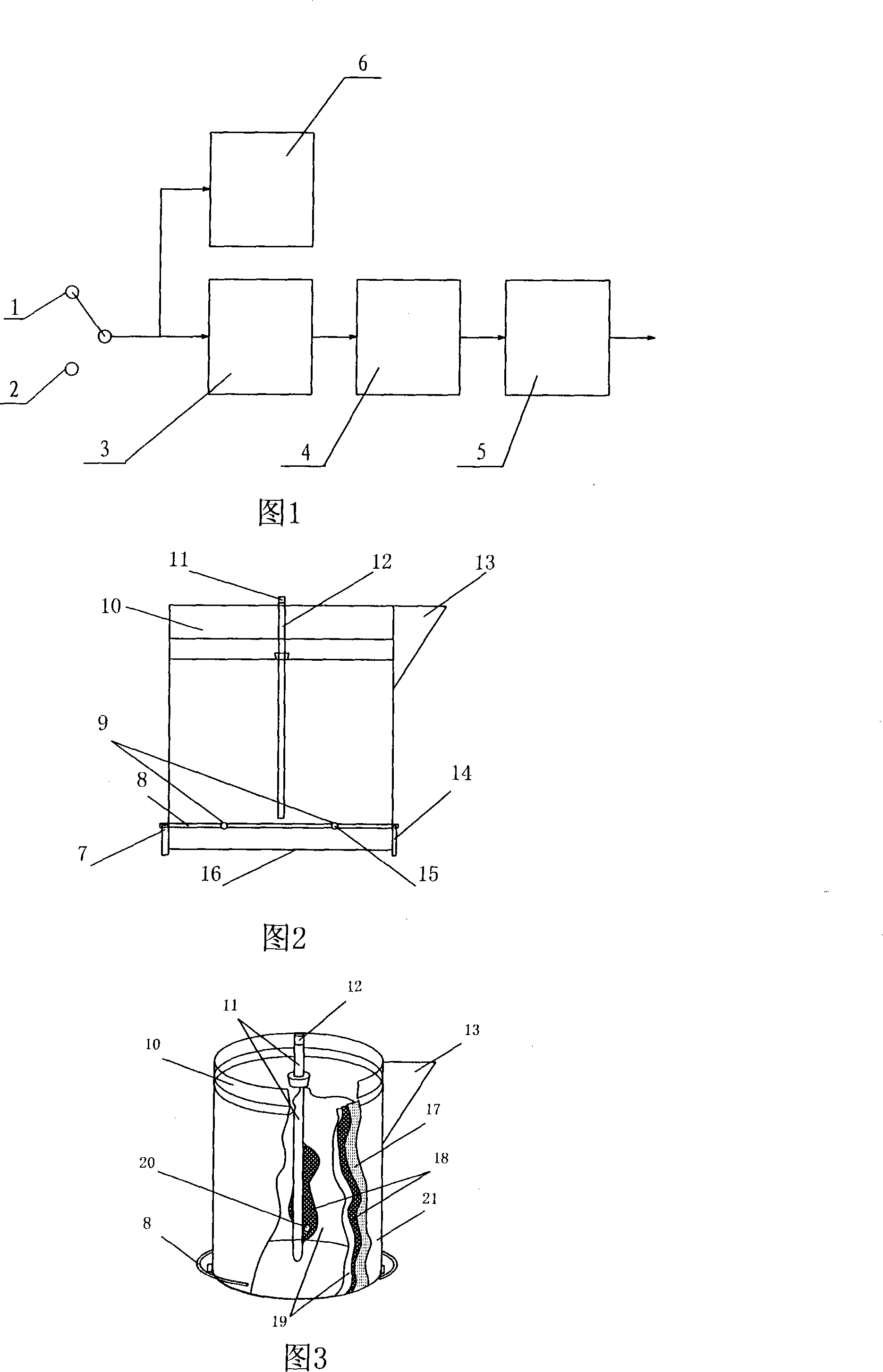

[0059] Implement the used container structure of soft soil of the present invention, silt dehydration treatment method as shown in Figure 2, Figure 3, Figure 4, the shape of container can be hollow circular cylinder or hollow square cylinder or hollow rectangular cylinder, the top of container Feed chute 13 is arranged, and there is a movable bottom door 16 for unloading at the bottom. The movable bottom door 16 is fixed on the container by a bottom door fastener 14. There is a bottom door stopcock 7 for switching on the movable bottom door 16. There is a piston-type top cover 10 on the upper part, an anode rod 12 is arranged in the inner center of the container, and a percolation layer 19, a cathode mesh layer 18, a diversion layer 17, and a shell 21 are arranged on the container wall from the inside to the outside, and the diversion layer is provided with The small hole 20, the connecting pipe 9 connected to the cathode network layer passes through the small hole and then con...

Embodiment 2

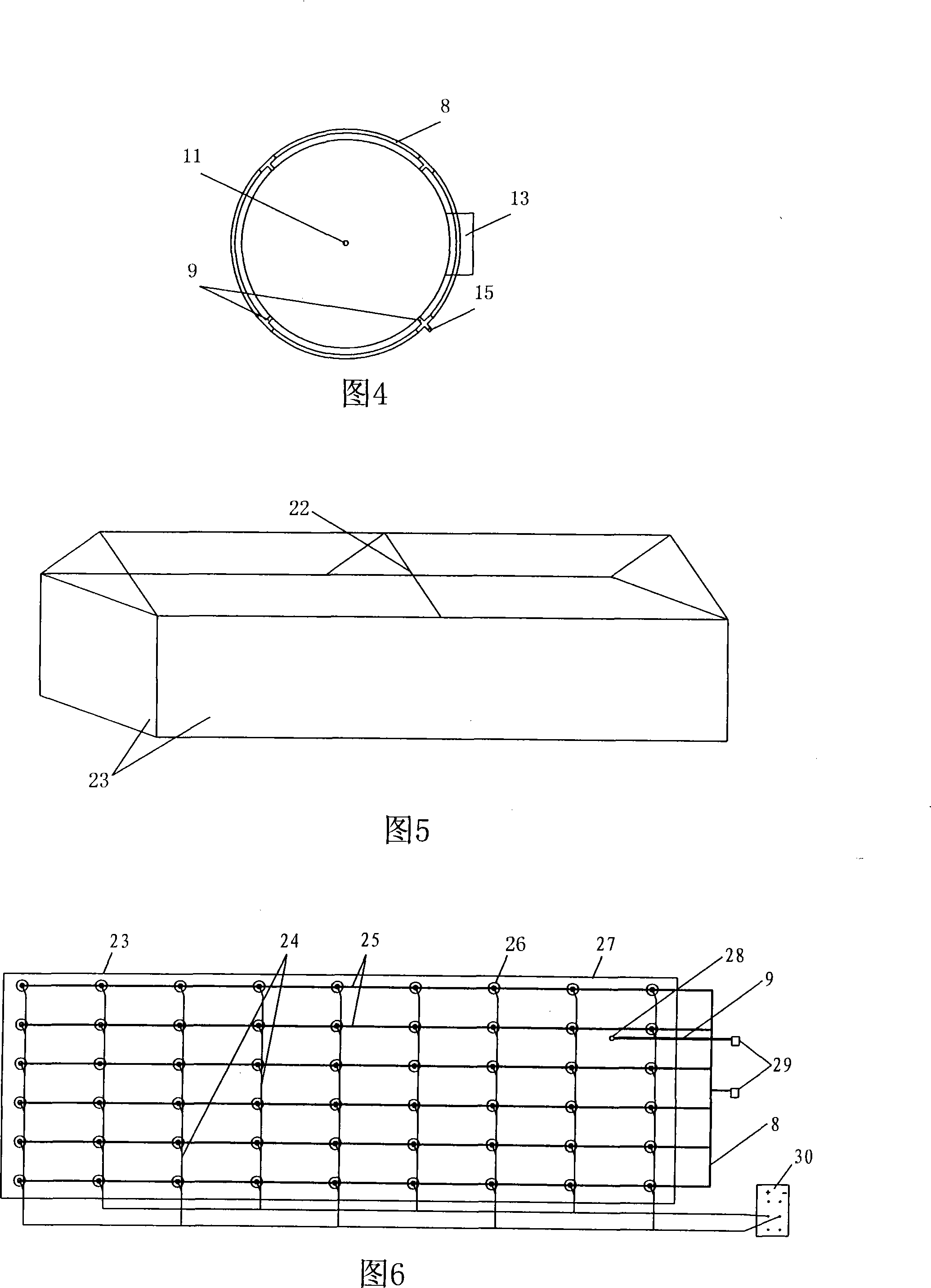

[0062] In a test base in Zhejiang, the sludge is treated with a tank with a depth of 3 meters, a width of 5 meters and a length of 20 meters. The structure of the groove is shown in Figure 5 and Figure 6: the top of the groove 23 is provided with a mesh eyelet film 27 covering the notch, the top of the film is provided with a waterproof arch 22, and the electroosmotic device adopts multiple rows of composite pipes 26 as Yin and Yang. Anode electrode, composite pipe 26 connects horizontal drainage pipe 25, horizontal drainage pipe 25 connects water collection pipe 8, water collection pipe 8 connects vacuum pump 29, anode and cathode composite pipe connect the positive and negative poles of pulse type electroosmosis power supply 30 through energization line 24, electric The device for maintaining the capillary structure during the infiltration process adopts vacuum preloading device, static load device and low-medium energy dynamic compaction device.

[0063] Dehydration is carr...

Embodiment 3

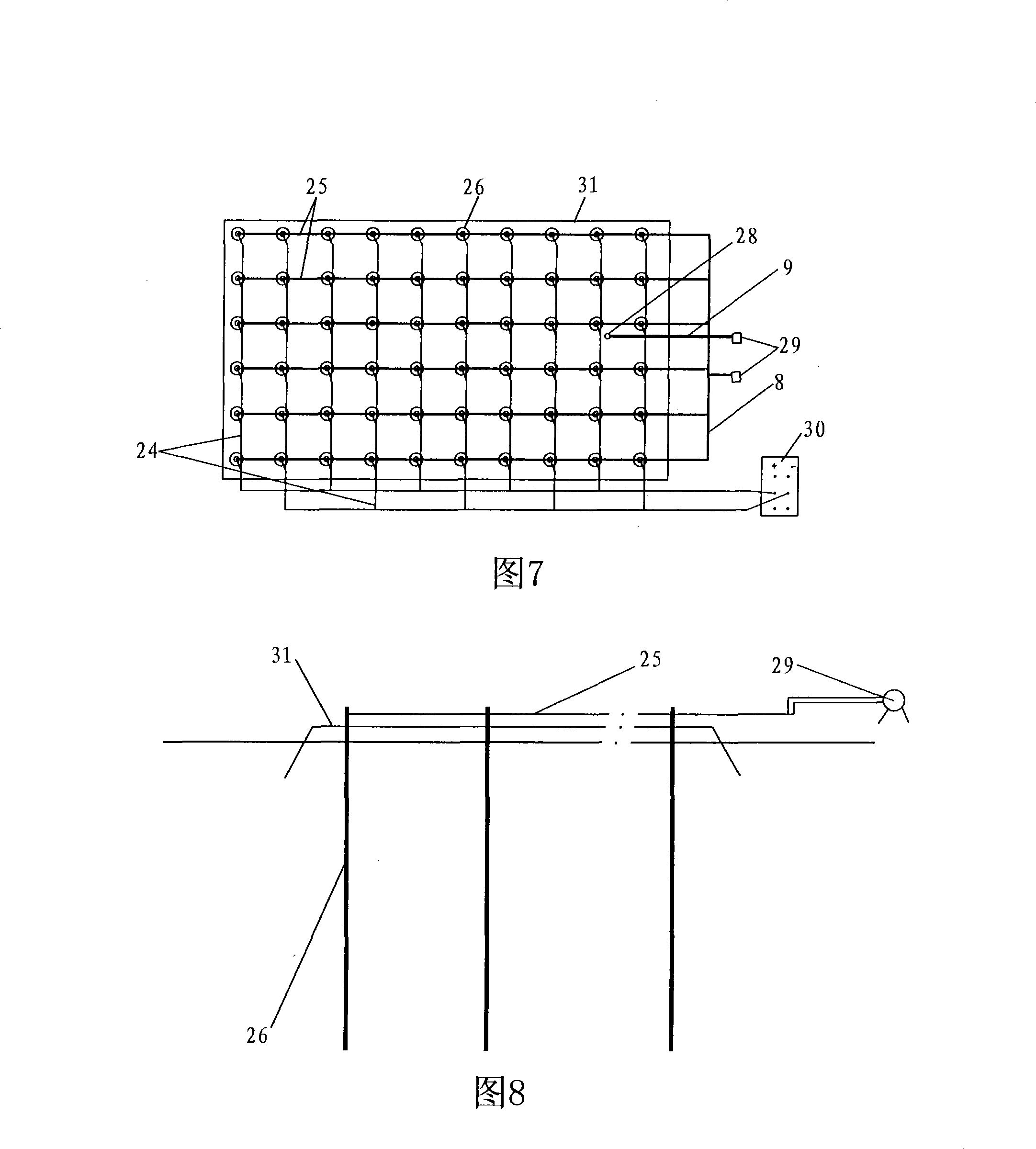

[0072] At a construction site in Zhejiang, it is required to deal with a soft soil field with a depth of 6 meters. The layout of the venue and equipment is shown in Figure 7 and Figure 8.

[0073] The operation steps are as follows:

[0074] 1) Roughly level the soft soil field, and set up a 6-meter-deep grouting curtain around the soft soil field to prevent the water outside the field from seeping into the field.

[0075] 2) The cathode and the anode of the electroosmotic device are arranged according to the specifications and patterns of embodiment 2, the cathode and the anode adopt composite tube 26, the composite tube is 6 meters long, and the distance between the composite tubes is 0.5 meters, the cathode and the anode composite tube are passed through The electrification line 24 is respectively connected to the negative pole and the positive pole of the pulsed electroosmotic power supply 30 , the output voltage of the pulsed electroosmotic power supply: 0-200V, the outp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Carrying capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com