Method for ultrasonic extraction and distillation separation of benzene-cyclohexane and benzene-n-heptane

A technology of extractive distillation and cyclohexane, applied in the direction of distillation purification/separation, etc., can solve the problems of spending a lot of energy, easy precipitation of salt components, etc., and achieve the effect of improving relative volatility, good separation effect, and improving separation effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Embodiment 1: Separation of benzene-n-heptane near-boiling point system by ultrasonic extraction and distillation

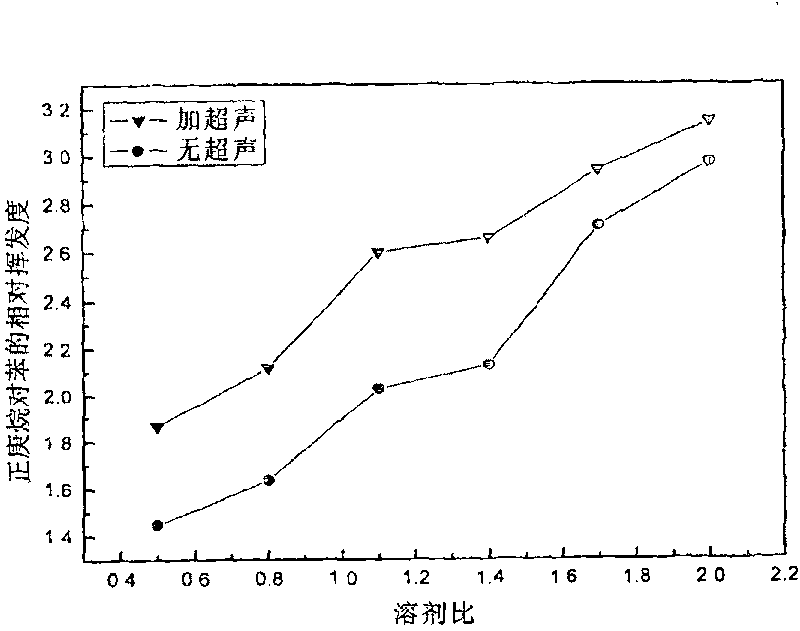

[0016] Benzene and n-heptane mixture (n-heptane molar content is 6.74%) is mixed with a certain amount of furfural solvent (solvent ratio 0.5: 1~2: 1), placed in an ultrasonic field for 30min, (ultrasonic field condition is output frequency 22KHz, power is 240W). Pour the material into an extractive still for distillation. The operating pressure of the extractive distillation is normal pressure, the temperature of the kettle is constant at 90-120°C, and the distillate is a mixture of n-heptane and benzene. Samples were taken every 15 min for analysis. Distillation was carried out under the same conditions without the addition of an ultrasonic field, and samples were taken for analysis. The relative volatility results of the system with and without ultrasound are as follows: figure 1 shown.

[0017] Depend on figure 1 It can be seen that under the sam...

Embodiment 2

[0018] Embodiment 2: Ultrasonic extraction distillation to separate benzene-cyclohexane azeotrope

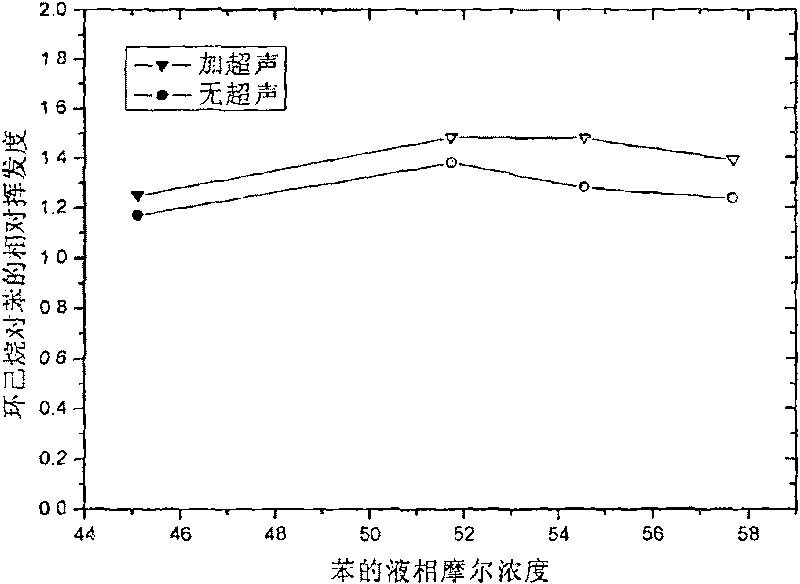

[0019] The mixture of benzene and cyclohexane close to the azeotrope composition (the molar content of benzene is 45% to 58%) is mixed with a certain amount of DMF solvent (solvent ratio 0.2), and the material is poured into the extractive distillation still for distillation. The extractive distillation operating pressure was normal pressure, the kettle temperature was 90-120°C, and an ultrasonic field was intermittently added every 10min (ultrasonic field conditions were: output frequency 22KHz, power 308W) for 10min. When the vapor and liquid temperatures are equal and constant at 80-85°C, take the distillate for detection and analysis by chromatography. Distillation was carried out under the same conditions without the addition of an ultrasonic field, and samples were taken for analysis. The relative volatility results of the system with and without ultrasound are as follows...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com