Method for producing polyether-type defoaming agent

A production method and antifoaming agent technology, which is applied in the production field of polyether type antifoaming agent, can solve the problems such as running out of materials, achieve the effect of small temperature and pressure increase, good mixing effect, and prevent overheating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

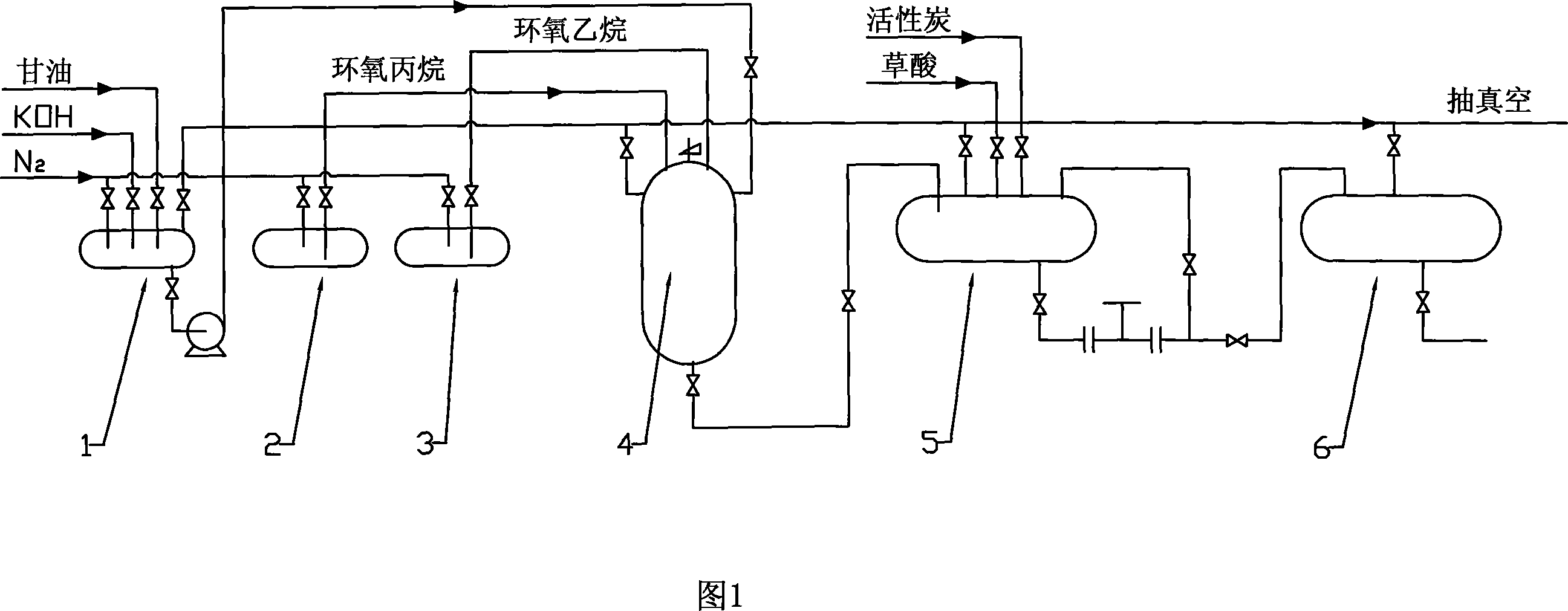

[0023] The present invention will be further described below in conjunction with the accompanying drawings and a preferred specific embodiment, so as to help understand the content of the present invention.

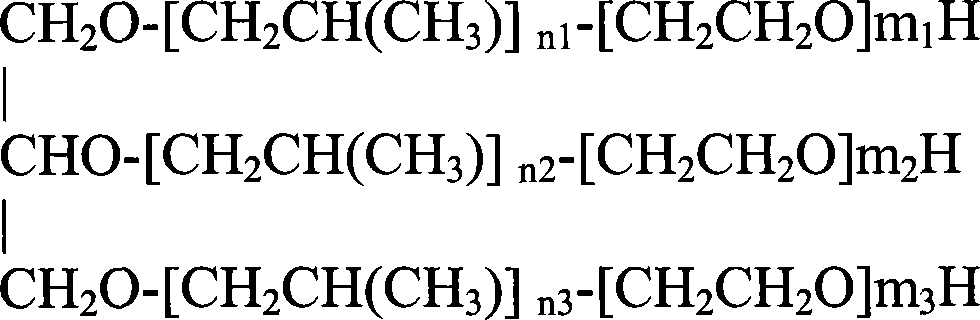

[0024] The polyether-type defoamer of this embodiment also adopts a batch-type production process, using glycerin as an initiator, and under the action of alkali catalysis, it is formed by ring-opening polymerization with propylene oxide and ethylene oxide in a polymerization kettle , and then neutralized and decolorized.

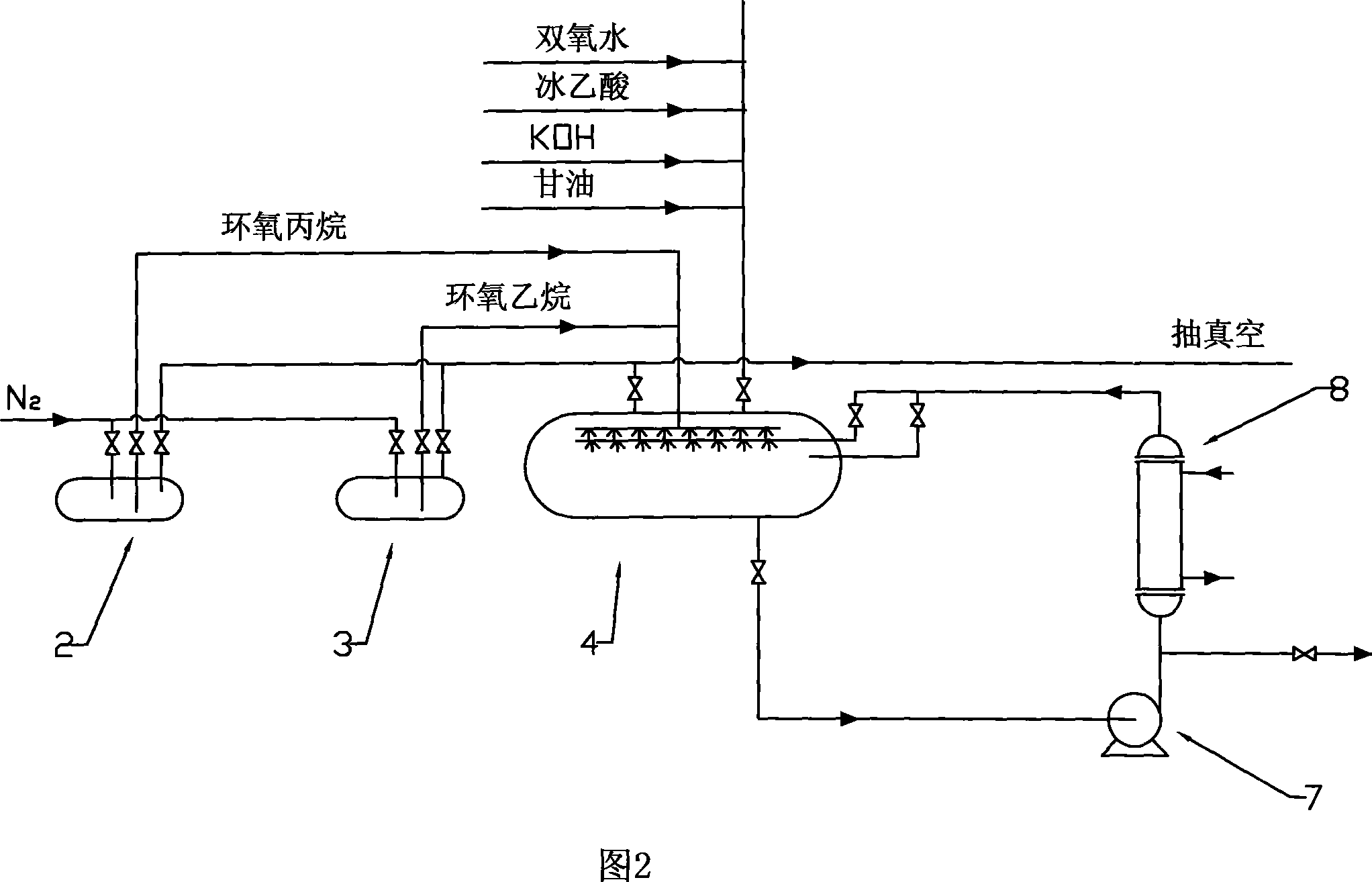

[0025] In conjunction with Figure 2, its production process is described in detail as follows:

[0026] 1. Polymerization process

[0027] (1) Enter glycerin and potassium hydroxide in the polymerization kettle and set up the external circulation of the kettle: open the vacuum valve of the polymerization kettle 4 to evacuate, drop into the starting material glycerol 90kg of reaction in the kettle, add catalyst potassium hydroxide from the solid feed p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com