Special iron oxide yellow pigment for tobacco and production method thereof

A technology of iron oxide yellow and its production method, which is applied in the fields of tobacco, tobacco treatment, application, etc., can solve the problems of unsatisfactory product performance, consumption of non-renewable resources of iron, and effective control of the content, and achieve good color covering power and saving The effect of iron resources and fine particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

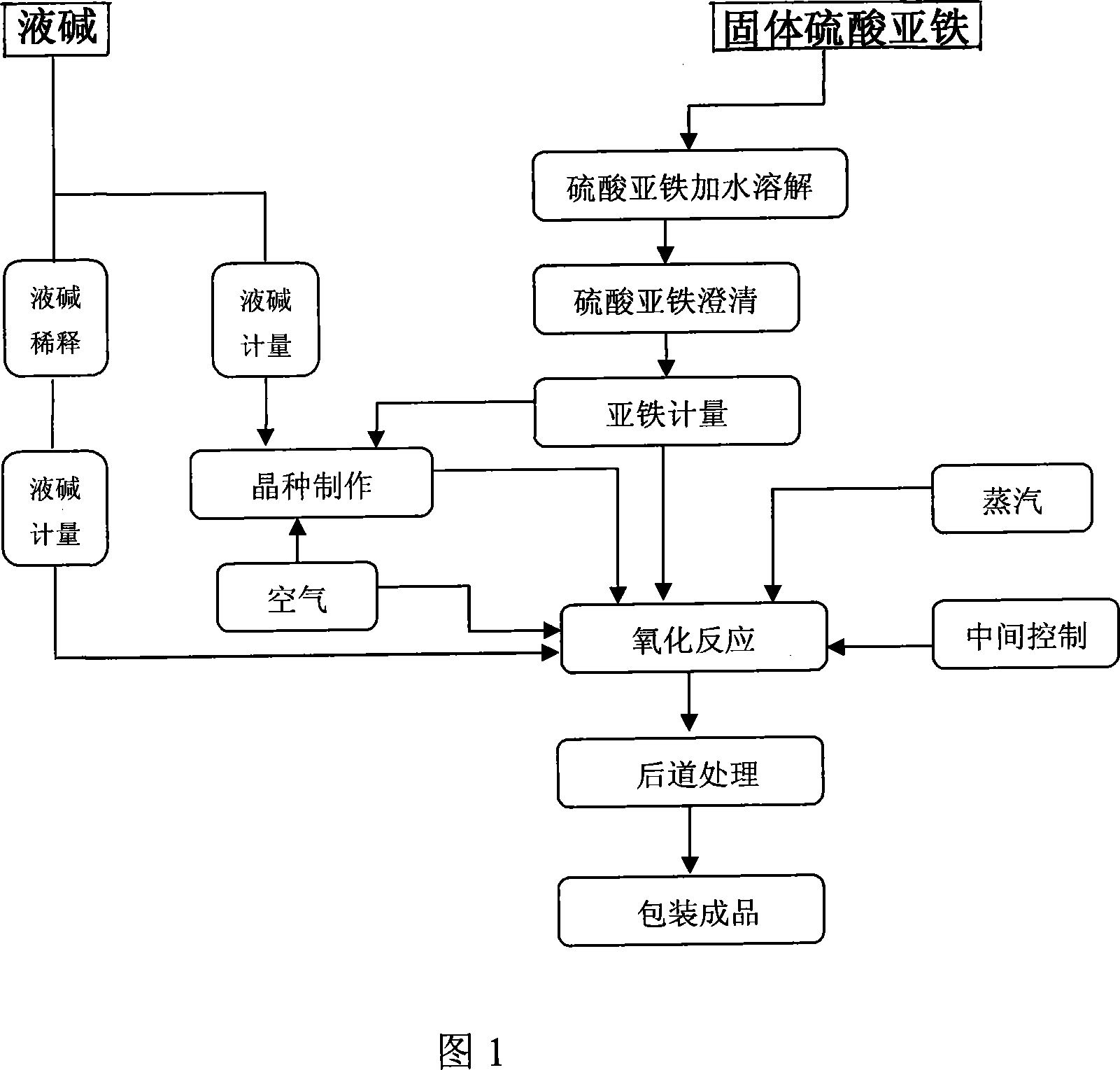

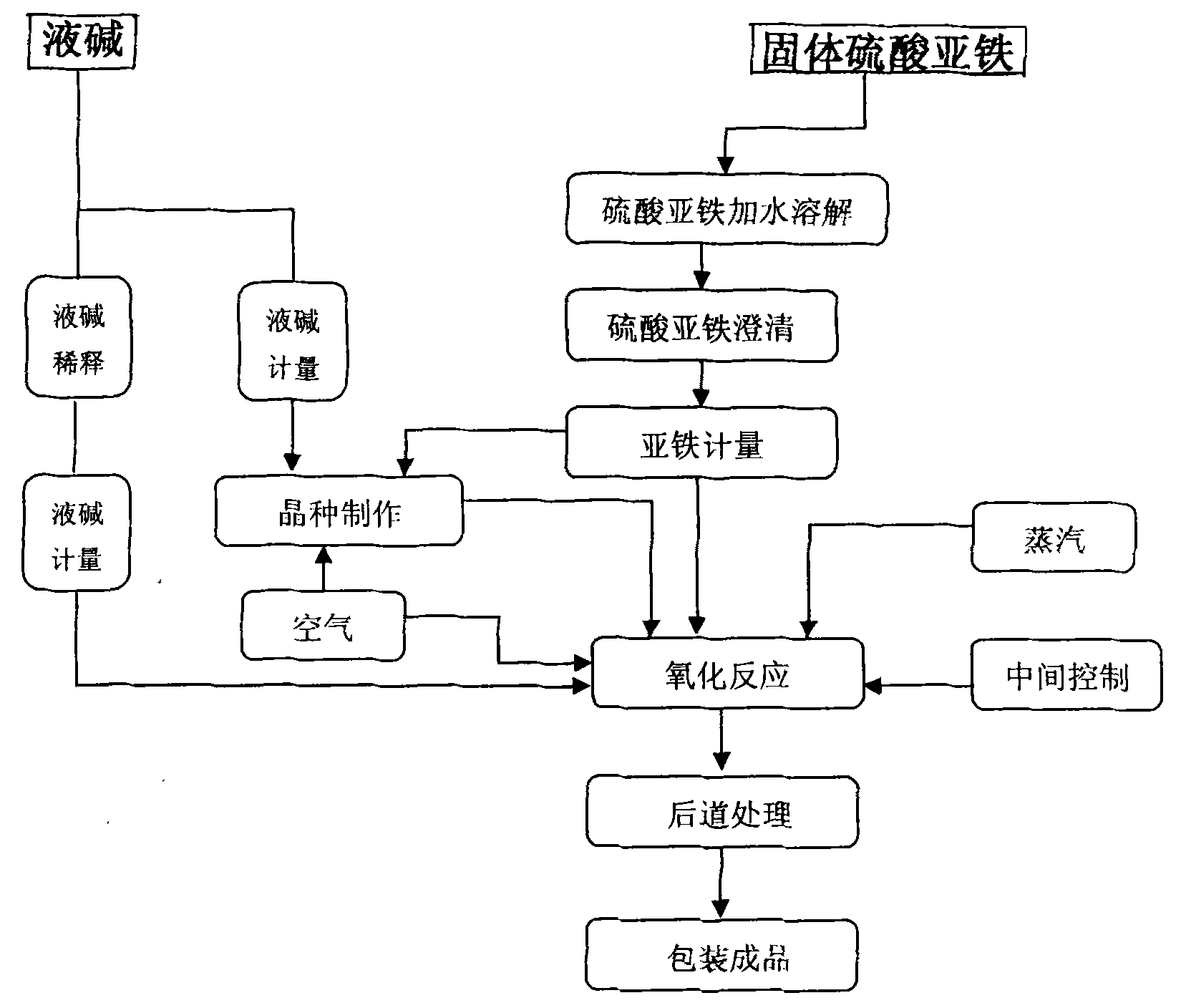

[0018] Embodiment one, such as figure 1 As shown, the iron oxide yellow pigment in this example is formed by dissolving solid ferrous sulfate with a content of 80-88% in water, and reacting with a sodium hydroxide solution with a concentration of 32% after clarification.

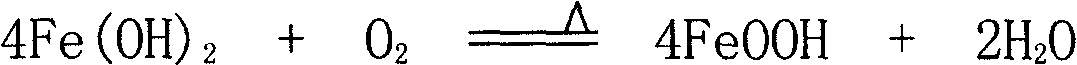

[0019] The production method of the iron oxide yellow pigment comprises seed crystal preparation and two-step oxidation, and the process steps are as follows:

[0020] i) seed crystal preparation,

[0021] a) adding water to dissolve and clarify the solid ferrous sulfate with a content of 81.6%, and claiming that 1894kg of ferrous sulfate solution with a content of about 39.6% (100% equivalent content is 750kg) is dropped into the seed crystal reaction tank;

[0022] b) 210kg of sodium hydroxide solution with a concentration of 32% is added to the seed crystal reaction tank;

[0023] c) At normal temperature, make ferrous sulfate and sodium hydroxide carry out neutralization reaction, pass into air oxidati...

Embodiment 2

[0028] Embodiment two, such as figure 1 As shown, the iron oxide yellow pigment of this example is formed by reacting 88% solid ferrous sulfate with water and reacting with 32% sodium hydroxide solution after clarification.

[0029] The production method of the iron oxide yellow pigment comprises seed crystal preparation and two-step oxidation, and the process steps are as follows:

[0030] i) seed crystal preparation,

[0031] a) adding water to dissolve and clarify the solid ferrous sulfate with a content of 87.6%, and claiming that 2440kg of a ferrous sulfate solution with a content of about 41.0% (100kg for a content of 100%) is dropped into a seed crystal reaction tank;

[0032] b) 280 kg of sodium hydroxide solution with a concentration of 32% is added in the seed crystal reaction barrel;

[0033] c) At normal temperature, make ferrous sulfate and sodium hydroxide carry out neutralization reaction, pass into air oxidation, oxidation time is 16.5 hours, and finally ferr...

Embodiment 3

[0038] Embodiment three, such as figure 1 As shown, the iron oxide yellow pigment of this example is formed by reacting 86% solid ferrous sulfate with water, clarifying and reacting with 32% sodium hydroxide solution.

[0039] The production method of the iron oxide yellow pigment comprises seed crystal preparation and two-step oxidation, and the process steps are as follows:

[0040] i) seed crystal preparation,

[0041] a) adding water to dissolve and clarify the solid ferrous sulfate with a content of 86.3%, and claiming that 2200 kg of a ferrous sulfate solution with a content of about 38.6% (converted to a content of 100% is 850 kg) is dropped into a seed crystal reaction tank;

[0042]b) 240kg of sodium hydroxide solution with a concentration of 32% is dropped into the seed crystal reaction barrel;

[0043] c) at normal temperature, make ferrous sulfate and sodium hydroxide carry out neutralization reaction, pass into air oxidation, oxidation time is 14 hours, and fina...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com