Method for preparation of nanometer clearance electrode

A nano-gap electrode and gap technology, which is applied in the direction of semiconductor devices, can solve problems such as difficult to realize, and achieve the effects of convenient operation, improved production efficiency, effective and precise control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] The preparation method of the present invention is based on the principle that in a scanning electron microscope, a pre-prepared electrode is irradiated with a high-density electron beam, and the electron beam and the secondary electrons generated by it will cause complex chemical reactions to occur on the molecules adsorbed on the surface of the electrode. reaction, decomposed and deposited on the surface of the electrode, so that the electrode becomes wider and the distance between the electrodes gradually becomes smaller.

[0026] Specifically, the preparation method of the nano-gap electrode provided by the present invention utilizes electron beam induced deposition technology, and its steps are as follows:

[0027] a) Prepared by current common electrode preparation methods (such as: photolithography technology, electron beam exposure technology, current ablation technology, junction breaking technology, electrochemical deposition technology, nanowire template techn...

Embodiment 1

[0037] Taking the preparation of carbon nanotube electrodes as an example

[0038] In the first step, carbon nanotubes are dispersed in an ethanol solution. Then the solution was dropped on the titanium-gold electrodes with a spacing of 2 microns, and the distribution of carbon nanotubes on the titanium-gold electrodes was observed through a scanning electron microscope. (figure 1)

[0039] In the second step, a large voltage is applied to both ends of the titanium gold electrode connected with carbon nanotubes to burn the carbon nanotubes, thereby forming a nanoscale gap in the middle ( figure 2 a).

[0040] In the third step, the carbon nanotube electrode is placed in the vapor of toluene molecules for 1 day, so that the toluene molecules are adsorbed on the surface of the carbon nanotube electrode.

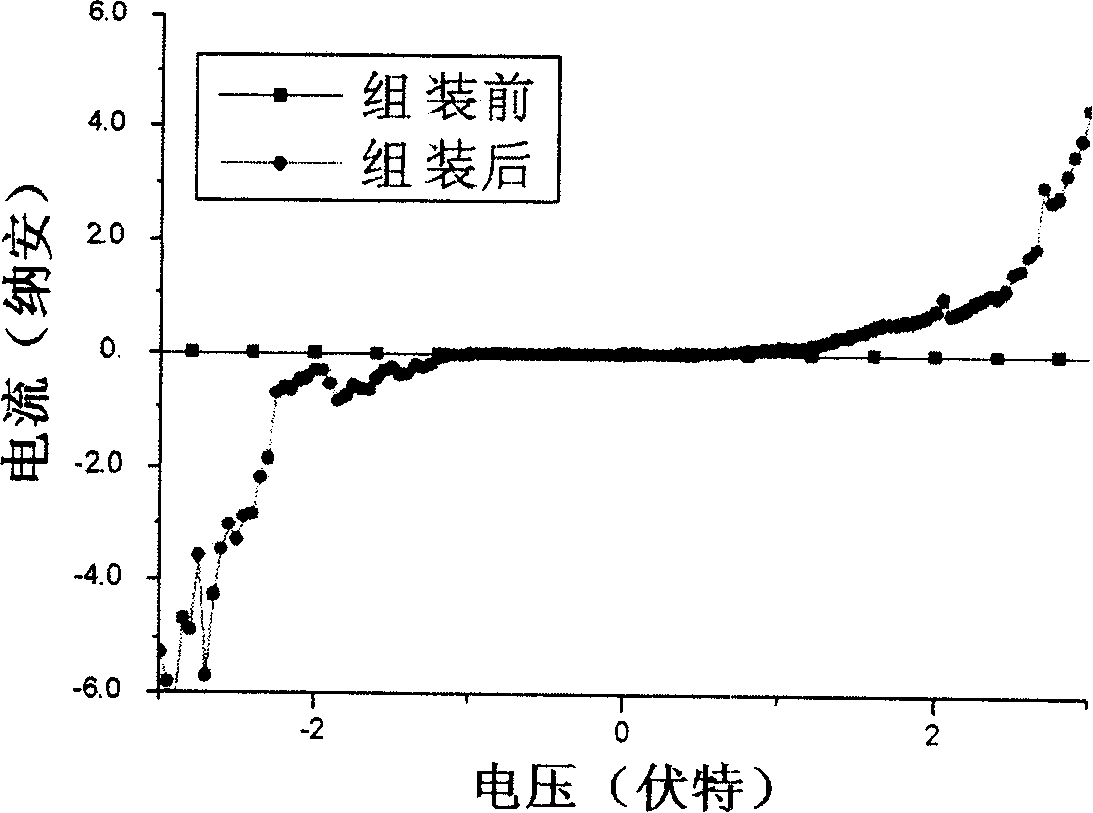

[0041] In the fourth step, the carbon nanotube electrode is placed in the scanning electron microscope, and the electron beam (energy is 15 keV, density is 10 7 Amps per sq...

Embodiment 2

[0044] According to the preparation method in Example 1, the difference is: in the third step, the carbon nanotube electrode is placed in the vapor of ethanol for 2 days. In the fourth step, the electron beam density is 2×10 6 Amperes per square meter. In the fifth step, when the electrode gap reaches 5 nanometers, stop the electron beam irradiation immediately. A carbon nanotube electrode with an electrode gap of 5 nm was prepared. Such as Figure 4 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com