Method for preparation of high-density lithium ion battery anode material nickel cobalt manganic acid lithium

A technology for nickel-cobalt lithium manganate and lithium-ion batteries is applied in the field of preparation of high-density lithium-ion battery positive electrode material nickel-cobalt lithium manganate, which can solve the problems of high consumption, long production cycle, unfavorable battery use, etc., and achieve high tap density. and mass specific capacity, the effect of short production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

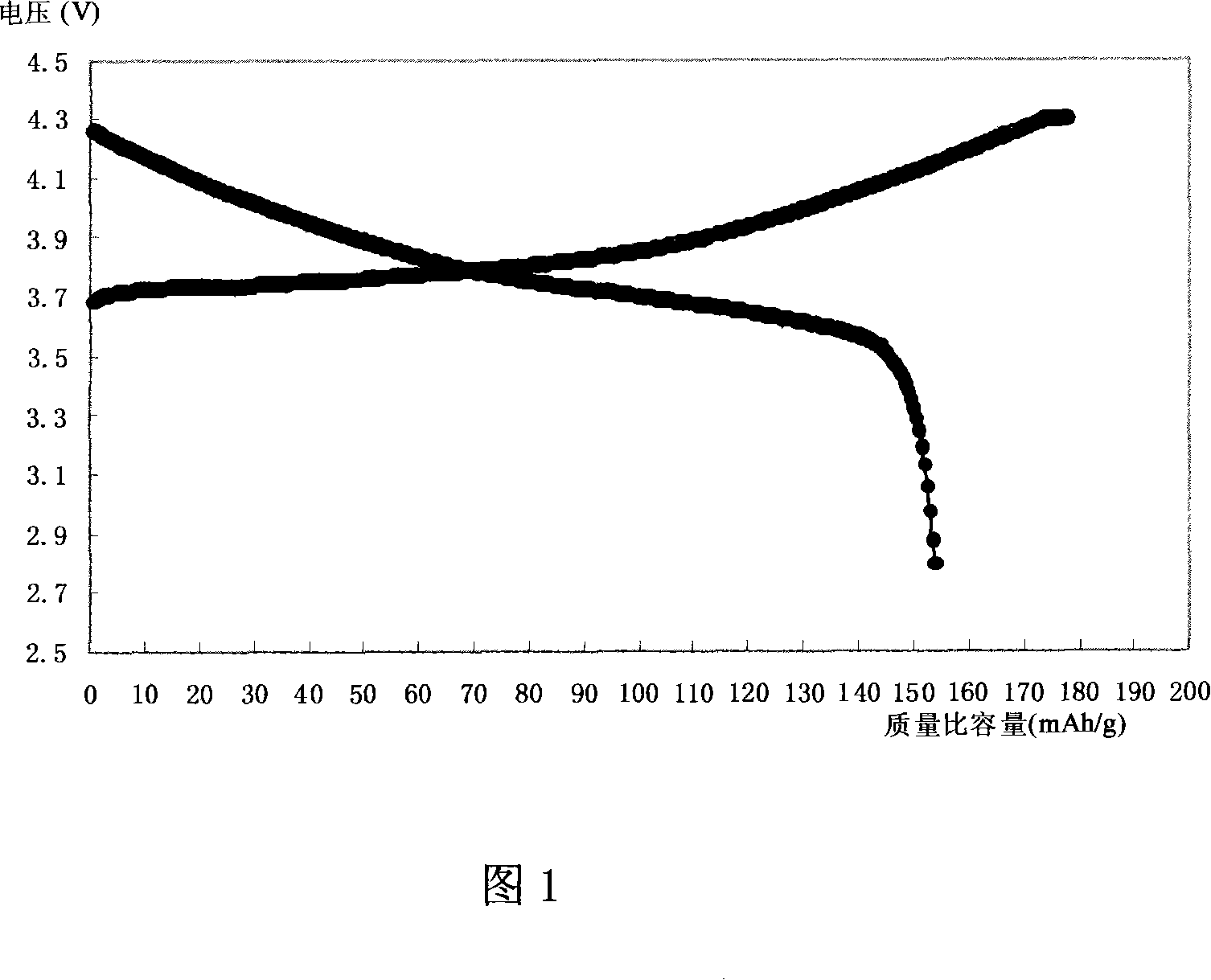

[0020] Mix nickel oxide, cobalt carbonate, and manganese carbonate uniformly at a molar ratio of Ni:Co:Mn=1:1:1, heat and sinter at a heating rate of 3-5°C / min to 600°C, and hold at 600°C at a constant temperature of 6 hour, after cooling, ball milling and sieving (Ni 1 / 3 co 1 / 3 mn 1 / 3 ) 3 o 4 oxide.

[0021] Will (Ni 1 / 3 co 1 / 3 mn 1 / 3 ) 3 o 4 Oxide and lithium carbonate are mixed uniformly at a molar ratio of Li: (Ni+Co+Mn) at a ratio of 1:1.1, then heated and sintered at a heating rate of 3 to 5°C / min to 900°C, and then kept at 900°C After 16 hours, after cooling, ball milling and sieving, Li was obtained 1.1 Ni 1 / 3 co 1 / 3 mn 1 / 3 o 2 Cathode material. Then conduct the first charge and discharge test.

Embodiment 2

[0023] Mix nickel oxide, cobalt carbonate, and manganese carbonate uniformly at a molar ratio of Ni:Co:Mn=1:1:1, heat and sinter at a heating rate of 3-5°C / min to 500°C, and keep the temperature at 500°C for 12 hour, after cooling, ball milling and sieving (Ni 1 / 3 co 1 / 3 mn 1 / 3 ) 3 o 4 oxide.

[0024] Will (Ni 1 / 3 co 1 / 3 mn 1 / 3 ) 3 o 4 Oxide and lithium hydroxide are mixed uniformly at a molar ratio Li: (Ni+Co+Mn) of 1:1.1, then heated and sintered to 1100°C at a heating rate of 3-5°C / min, and then reheated at 1100°C. Constant temperature for 4 hours, after cooling, ball milling and sieving, Li 1.1 Ni 1 / 3 co 1 / 3 mn 1 / 3 o 2 Cathode material. Then conduct the first charge and discharge test.

Embodiment 3

[0026] Mix nickel hydroxide, cobalt carbonate, and manganese carbonate uniformly at a molar ratio of Ni:Co:Mn=1:1:1, heat and sinter at a heating rate of 3-5°C / min to 800°C, and hold at a constant temperature of 800°C After 10 hours, after cooling, ball milling and sieving, (Ni 1 / 3 co 1 / 3 mn 1 / 3 ) 3 o 4 oxide.

[0027] Will (Ni 1 / 3 co 1 / 3 mn 1 / 3 ) 3 o 4 Oxide and lithium carbonate are mixed evenly at a molar ratio of Li: (Ni+Co+Mn) at a ratio of 1:1.1, then heated and sintered at a heating rate of 3 to 5°C / min to 800°C, and then kept at 800°C After 30 hours, after cooling, ball milling and sieving, Li 1.1 Ni 1 / 3 co 1 / 3 mn 1 / 3 o 2 Cathode material. Then conduct the first charge and discharge test.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com