Composite material satellite antenna reflection surface and manufacturing process thereof

A technology for composite materials and satellite antennas, which is applied in the fields of antennas, chemical instruments and methods, and natural mineral layered products, etc., and can solve the problems of reduced precision of antenna reflective surfaces, difficulties in production and processing of aluminum honeycomb sandwich cores, and sandwich composite material structures. defects and other problems, to achieve the effect of light weight, high rigidity and simple manufacturing method

Inactive Publication Date: 2010-11-10

吴豪 +1

View PDF0 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The former is prone to uneven foaming, and secondary foaming is prone to occur after the molding process is completed, resulting in a decrease in the accuracy of the antenna reflective surface and affecting communication quality

In the latter, during the secondary processing of the foam core material, it is difficult to process the core material to coincide with the thin shell, resulting in defects in the sandwich composite structure

The composite material antenna surface with honeycomb sandwich core has high overall rigidity and is currently widely used in the field of composite material antenna surface. However, due to the difficulty in production and processing of the aluminum honeycomb sandwich core, the core material needs to undergo tedious surface treatment and printing. and because aluminum honeycomb is very difficult in making curved surface structures, especially when making large curved satellite antenna reflective surfaces, segmented aluminum honeycombs must be used for splicing, which leads to Structural defects have occurred. Although cementation is carried out between aluminum honeycomb joints, the coefficient of linear expansion used in carbon fiber composites is extremely low, and the coefficient of linear expansion of adhesives is often relatively large, which is likely to obscure the reflective surface. The leather is deformed due to thermal expansion and contraction, which reduces the surface accuracy and affects the communication quality

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

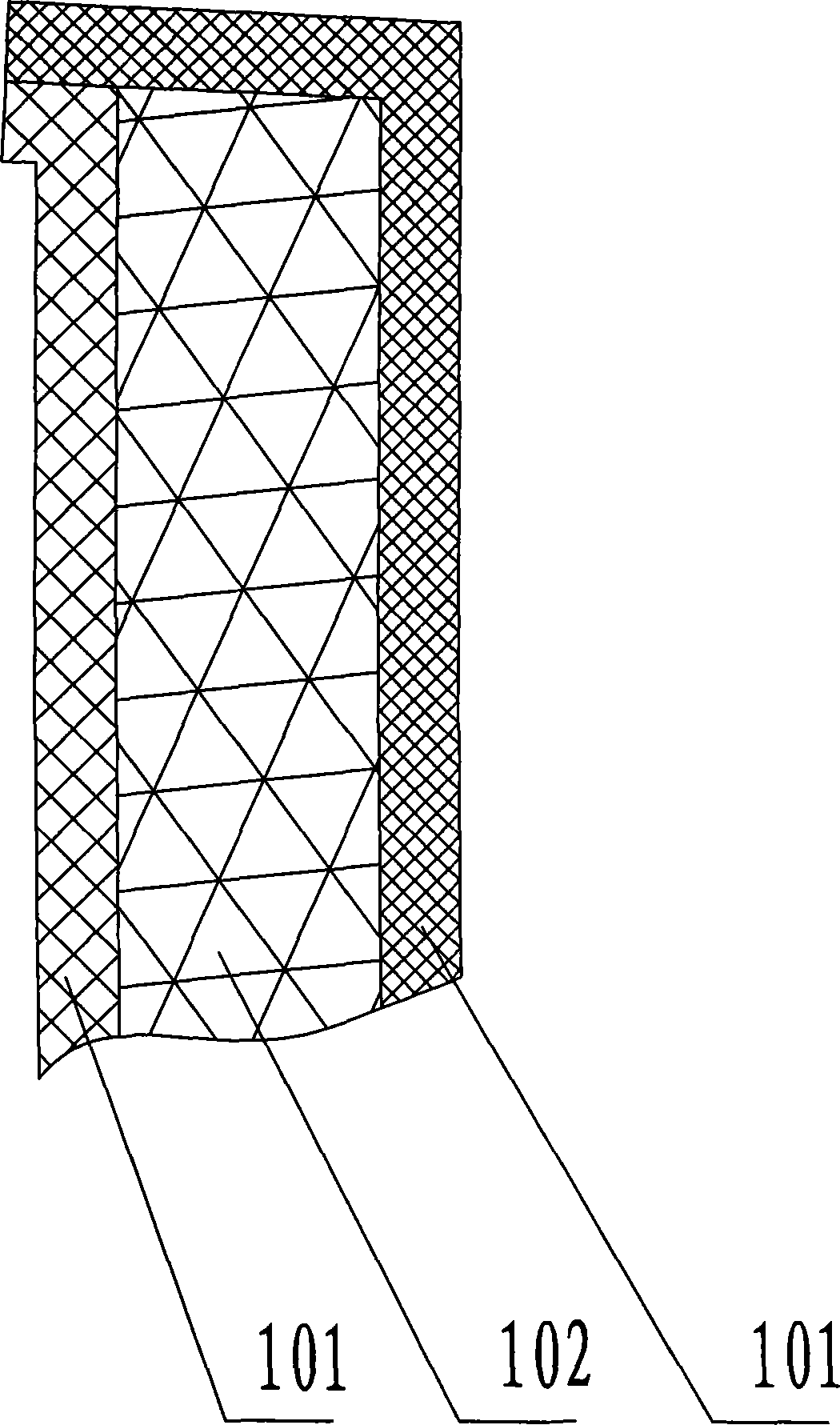

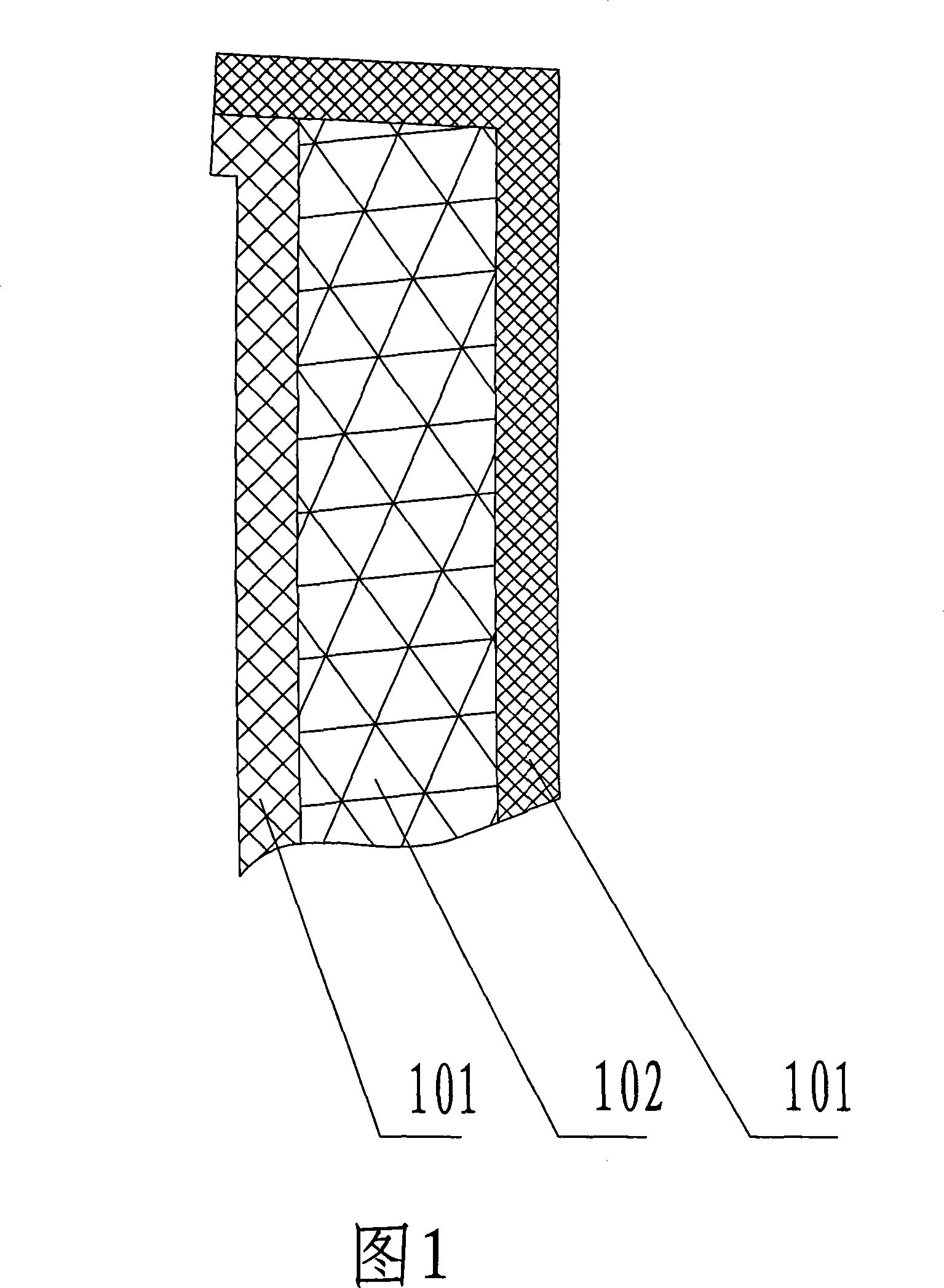

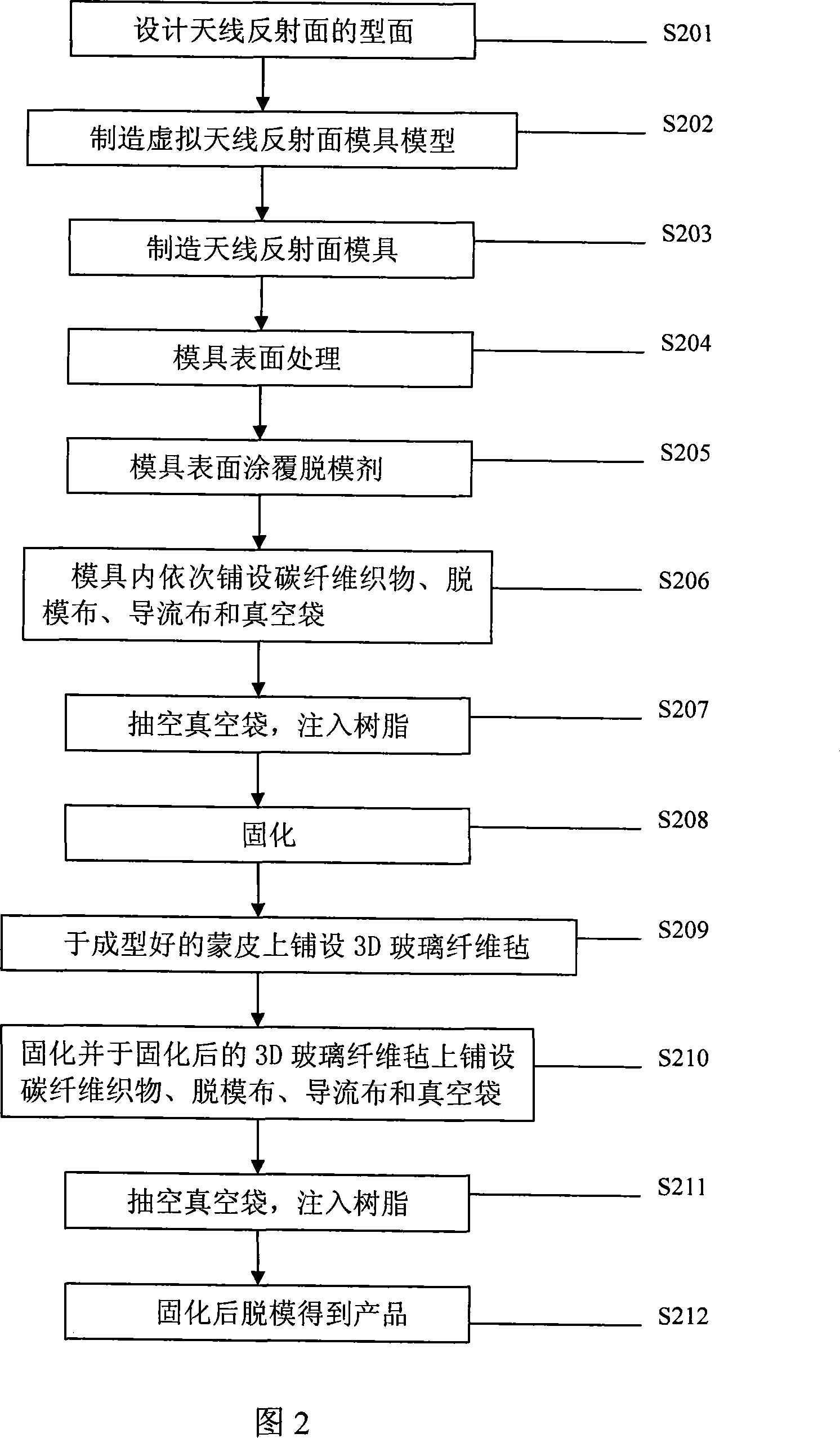

The invention relates to the technology field of communication and observation control, which provides a composite material satellite antenna reflection plane and the method for preparation. The composite material satellite antenna reflection plane adopts 3D glass fiber felt as core material, and adopts carbon fiber composite as covering sandwich type composite material satellite antenna reflection plane. Compared with the prior art, the invention has the following advantages: 1. shaped surface accuracy of the satellite antenna reflection plane is high and satellite signal gain is great, 2. quality of the reflection plane is light, and is fit for transportation, in particular to fitting for vehicle satellite antenna and portable satellite antenna, 3. integrality of the reflection plane isgood, hardness is great, thereby being capable of preferably retaining the shaped surface accuracy and bearing more wind load and impact load, 4. adopting the 3D glass fiber felt as the core material, the invention inaugurates a new technology of the sandwich composite material satellite antenna reflection plane, the technology is capable of producing heavy caliber satellite antenna reflection plane, and which is simple in manufacturing technology comparatively and low in the cost.

Description

Composite material satellite antenna reflector and manufacturing method thereof technical field The invention relates to the technical field of communication and measurement and control, in particular to a composite material satellite antenna reflection surface and a manufacturing method thereof. Background technique Carbon fiber composite materials (CFRP) are favored by aviation and aerospace departments for their extremely small linear expansion coefficient, high specific strength, specific elastic modulus, and the designability of physical and mechanical properties. At the same time, because the ratio of the elastic modulus to the product of density and linear expansion coefficient is much higher than that of metal materials, it is praised by antenna experts as an ideal antenna structure material. With the continuous advancement of aerospace technology, countries with relatively developed industries have developed CFRP molding technology as early as the 1970s. CFRP is ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): H01Q15/14B32B19/00B32B17/00

Inventor 吴豪吴雄芳

Owner 吴豪

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com