Acidophilus milk for child and preparing method thereof

A yogurt, children's technology, applied in food preparation, milk preparations, dairy products and other directions, can solve the problems of not easy for children to accept, unpleasant taste, small amount of addition, etc., to enhance immunity, health promotion function comprehensive, good The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Recipe (per Kg of raw materials):

[0033] raw material

Raw material requirements

added amount

milk

Fat ≥ 3.1%, protein ≥ 2.9%, non-fat milk solids ≥ 8.3%

83.96%

Total solids ≥ 94%

9%

Total solids ≥ 94%, protein ≥ 80%

6%

multi-vitamins

and amino acids

V A 1000-3000μg / g, V D 100-300μg / g, taurine

600-980mg / g

0.02%

complex minerals

preparation

Iron 100-400mg / g (ferrous sulfate 50%, iron pyrophosphate

+EDTA chelated iron 50%), zinc 80-350mg / g (zinc lactate)

40%, Zinc Gluconate 30%, Zinc Sulfate 30%), Calcium

100-400mg / g (50% calcium carbonate, 50% milk calcium)

0.02%

thickener

Total solids ≥ 94%

1%

flavor substances

0%

Streptococcus thermophilus, Lactobacillus bulgaricus, Bifidobacterium

0.4u / Kg

[0034] Preparation Process:

[003...

Embodiment 2

[0043] Recipe (per Kg of raw materials):

[0044] raw material

[0045] multi-vitamins

[0046] Preparation Process:

[0047] ①Mix milk, sucrose (white granulated sugar), milk protein powder, thickener and compound mineral preparation at 30℃;

[0048] ② Homogenize the above mixture at 40°C and 25MPa pressure;

[0049] ③ Then sterilize at 90°C for 10 minutes;

[0050] ④ Cool to 30°C, add flavor substances, inoculate lactic acid bacteria and ferment for 9 hours, then add multivitamins and amino acid preparations for the second homogenization under low pressure of 0.2Mpa;

[0051] ⑤ Cool to about 13°C to obtain the children's yogurt of the present invention.

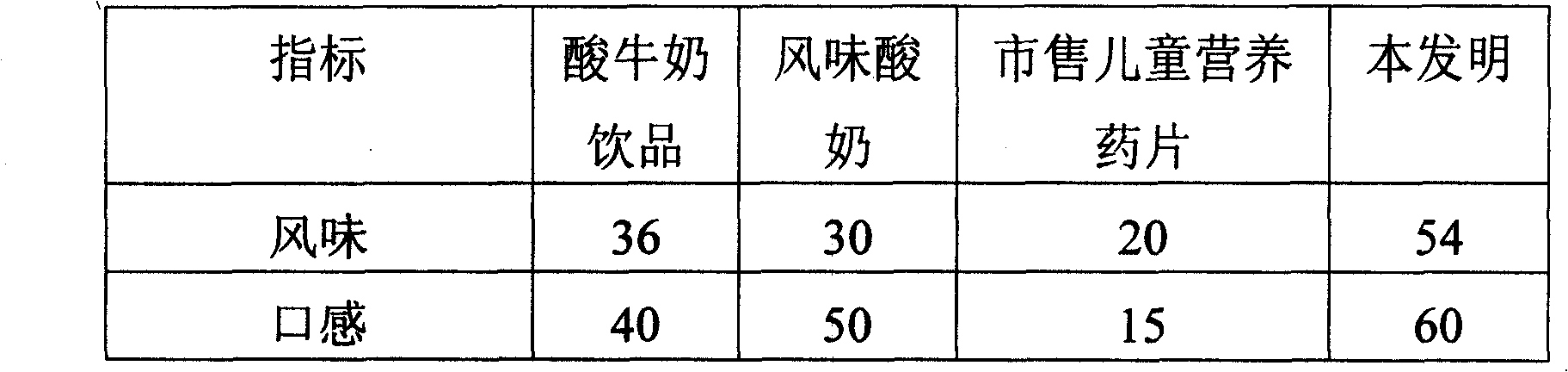

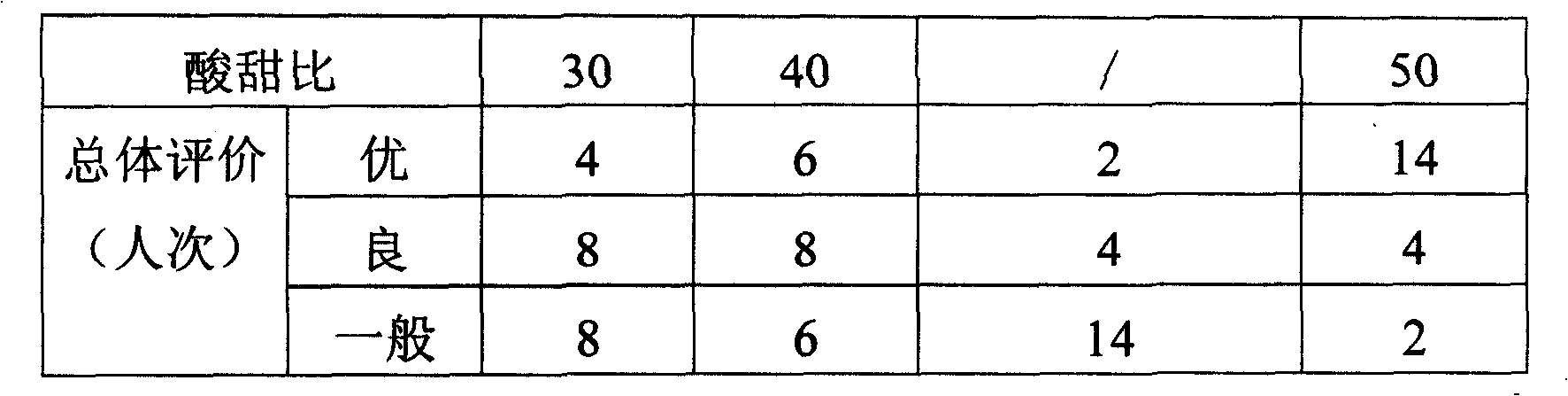

[0052] index:

[0053] project

[0054] iron

Embodiment 3

[0056] Recipe (per Kg of raw materials):

[0057] raw material

Raw material requirements

added amount

milk

Fat ≥ 3.1%, protein ≥ 2.9%, non-fat milk solids ≥ 8.3%

85.91%

Total solids ≥ 94%

8%

milk protein powder

Total solids ≥ 94%, protein ≥ 80%

5%

multi-vitamins

and amino acids

V A 1000-3000μg / g, V D 100-300μg / g, taurine

600-980mg / g

0.04%

complex minerals

preparation

Iron 100-400mg / g (ferrous sulfate 60%, iron pyrophosphate

40%), zinc 80-350mg / g (zinc lactate 40%, glucose

Zinc acid 40%, zinc sulfate 20%), calcium 100-400mg / g (carbon

Calcium acid 70%, calcium lactate 30%)

0.05%

thickener

Total solids ≥ 94%

0.7%

flavor substances

0.3%

Lactic acid bacteria

Streptococcus thermophilus, Lactobacillus bulgaricus, Lactobacillus casei

0.6u / Kg

[0058] Preparation Process:

[0059] ①Mix ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com