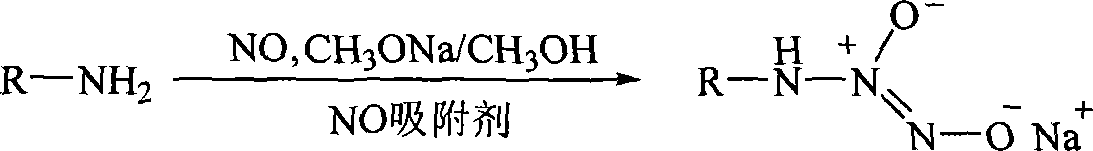

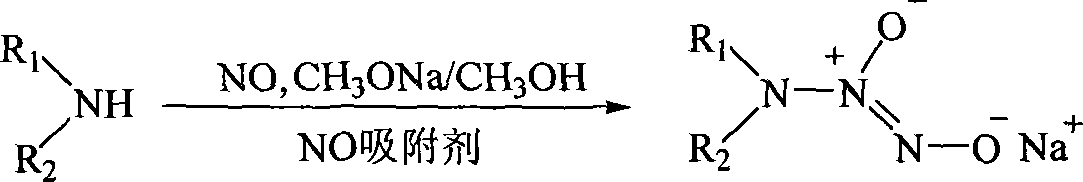

Method for preparing azo onium diol sodium salt

A technology of azonium glycol sodium salt and sodium methoxide, applied in the field of preparing azonium glycol sodium salt, can solve the problems of high equipment requirements, unfavorable large-scale production, inconvenient operation and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Preparation of Sodium Salt of Diethylaminoazonium Diol

[0029] In a 100mL three-necked flask device, add diethylamine (0.01mol), 50mL of anhydrous ether, 50mg of zeolite, 3.2mL of 25% sodium methoxide methanol solution, and use N 2 Replace the air in the reaction bottle for 3 times, and then replace the N in the reaction bottle with NO gas 2 3 times. Slowly introduce NO gas under stirring, and react at room temperature for 48h. Close the valve of the NO gas cylinder, pump out the remaining NO gas under reduced pressure, filter, wash the filter cake with 50 mL of ether, and dry in vacuo to obtain a crude product, which is dissolved in 10 mL of anhydrous methanol, filtered three times with a 0.22 μm organic filter membrane, and kept at room temperature Methanol was removed under reduced pressure and dried in vacuo to obtain a white solid powder, m.p.196-199°C, yield 34% [reported yield 26%, Bioorg.Med.Chem, 2007, 15: 6796-6801]. 1 H NMR (300MHz, D 2 O) δ: 1.12(t, J=...

Embodiment 2

[0031] Preparation of Sodium Salt of Pyrrolidinium Azonium Diol

[0032]In a 250mL three-necked flask device, add pyrrolidine (0.02mol), anhydrous ether 100mL, TiO 2 100mg, 6.4mL of 25% sodium methoxide in methanol. use N 2 Replace the air in the reaction device for 3 times, and then replace the N in the reaction device with NO gas 2 3 times. Slowly introduce NO gas under stirring, and react at room temperature for 48h. Close the valve of the NO gas cylinder, pump out the remaining NO gas, filter, wash the filter cake with 100mL ether, and dry it in vacuum. Redissolve in 20mL of anhydrous methanol, filter 3 times through a 0.22 μm organic filter, remove methanol under reduced pressure, and dry in vacuo to obtain a white solid powder, m.p.168-171°C, yield 89.5% [reported yield 54%, J . Med. Chem. 1997, 40(13): 1947-1954]. 1 H NMR (D 2 (2, 300 MHz) δ: 2.99 (m, 4H), 1.68 (m, 4H).

Embodiment 3

[0034] Preparation of piperidinium azonium diol sodium salt

[0035] In a 250mL three-necked flask device, add piperidine (0.03mol), anhydrous ether 150mL, TiO 2 150mg, 9.6mL of 25% sodium methoxide in methanol. use N 2 Replace the air in the reaction device for 3 times, and then replace the N in the reaction device with NO gas 2 3 times. Slowly introduce NO gas under stirring, and react at room temperature for 48h. Close the valve of the NO gas cylinder, pump out the unreacted NO gas, filter, wash the filter cake with 150mL ether, and dry it in vacuum. Redissolve in 30 mL of anhydrous methanol, filter 3 times through a 0.22 μm organic filter, remove methanol under reduced pressure, and dry in vacuo to obtain a white solid powder, m.p.277 ° C, yield 89.4% [yield 70%, J.Am.Chem .Soc.1961, 83:1819-1822]. 1 H NMR (D 2 (2, 300 MHz) δ: 3.10 (m, 4H), 1.53-1.59 (m, 6H). ,

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com