Preparation method of sulfadoxine

A technology based on sulfonamide and aminobenzenesulfonamide bases, which is applied in the field of sulfonamide preparation, can solve problems affecting the color of finished products, decomposition phenomena, corrosion, etc., achieve significant economic and environmental benefits, improve crude product quality and yield, The effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

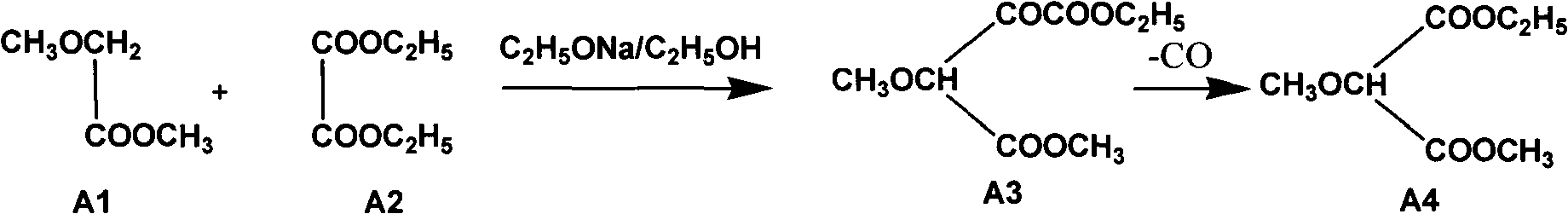

[0047] Embodiment 1 prepares 2-methoxy-methyl ethyl malonate (A4)

[0048] (1) The reaction equation is as follows:

[0049]

[0050] (2) See Table 1 for the feeding ratio.

[0051] Table 1

[0052] raw material name

Feeding amount (kg)

molecular weight

The molar ratio of

175

104

1

A2 (diethyl oxalate)

280

146

1.14

130

68

1.12

[0053] (3) The specific operation process is as follows:

[0054] Dry the reaction kettle (normal batch reaction reaction kettle does not need to be washed), mix methyl methoxyacetate and diethyl oxalate in a mixed ester pot, and cool to below 10°C, add to the reaction kettle, under stirring conditions, Pour the solid sodium ethoxide into the reaction kettle (the package of sodium ethoxide should not be disassembled, and the minimum package of sodium ethoxide should be used as the unit when feed...

Embodiment 2

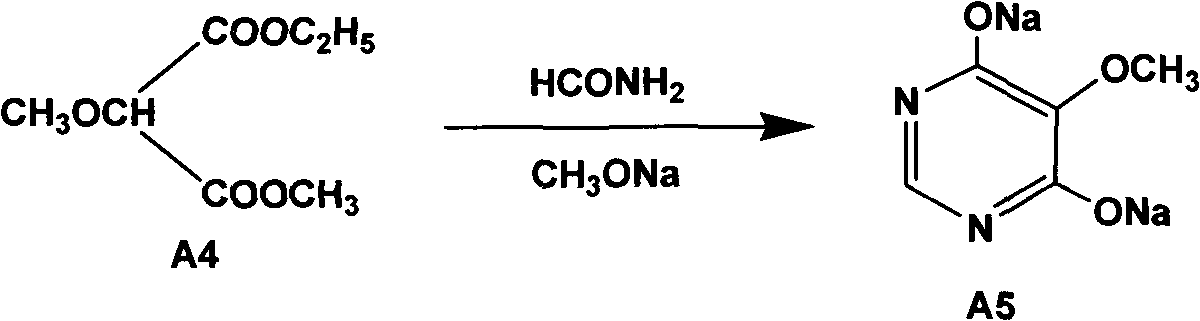

[0057] Embodiment 2 prepares cyclic compound-hydroxyl sodium salt (A5)

[0058] (1) The reaction equation is as follows:

[0059]

[0060] (2) The feeding ratio is shown in Table 2.

[0061] Table 2

[0062] raw material name

Feeding amount (kg)

molecular weight

The molar ratio of

A4 (Gradestone)

240

176

1

186

45

3.37

liquid sodium methoxide

830

54

3.46

[0063] (3) The specific operation process is as follows:

[0064] Dry the reactor first, put in liquid sodium methoxide, stir, heat to 60-68°C, add formamide, then add A4 obtained in step (1) evenly, control the temperature when adding to 65-70°C, and add time for 1-68°C After 1.5 hours, the addition is completed, and the heat preservation reaction is more than 0.5 hours. Recover methanol at room temperature, then recover methanol under reduced pressure until it does not come out, then add 1000L of water, ...

Embodiment 3

[0065] Embodiment 3 prepares chloride (A6)

[0066] (1) The reaction equation is as follows:

[0067]

[0068] (2) The feeding ratio is shown in Table 3.

[0069] table 3

[0070] raw material name

Feeding amount (kg)

molecular weight

The molar ratio of

A5 (the ring compound that embodiment 2 prepares)

240

186

1

Phosphorus oxychloride

825

153

4.17

Trichlorethylene

900

131

/

[0071] (3) The specific operation process is as follows:

[0072] In the reaction pot (covered tightly), press the pre-prepared phosphorus oxychloride. Turn on the reflux and hydrogen chloride gas absorption device, heat to 40°C with steam, turn off the steam to raise the temperature naturally, start to slowly add the cyclic compound-hydroxy sodium salt (A5), and control the adding speed, (pay attention to the sudden temperature phenomenon when adding, About ten to twenty minutes), add the rest ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com