Process for producing melanin, melanin produced by the process, functional film containing the melanin, and process for producing the same

A manufacturing method and technology of melanin, applied in the direction of organic dyes, polarizing elements, etc., can solve problems such as inability to specify structures, and achieve the effects of improving heterogeneity, improving variation, and good dyeing properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

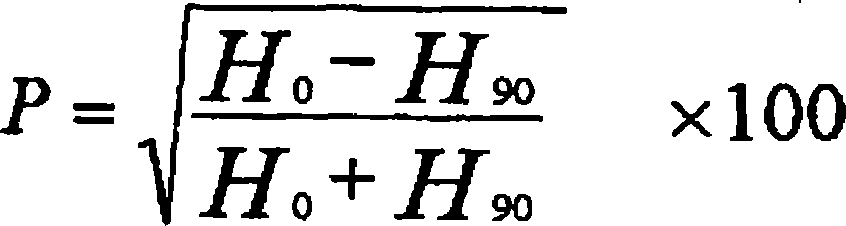

Method used

Image

Examples

Embodiment 1

[0087] In a 1-liter reactor equipped with a stirrer and an overflow, 200 g / L of catechol and 500 g / L of sodium persulfate were supplied at a rate of 2.7 mL / min, respectively. Use 100g / L sodium hydroxide to adjust the pH value to 9.5±0.2, and control the reaction temperature at 35°C±0.1°C. The overflowed reaction solution was adjusted to pH 1 with hydrochloric acid. The precipitated melanin was filtered and washed with a 50 g / L aqueous solution containing sodium sulfate until the pH value after washing reached 6. The washed melanin was dried at 70° C. for 1 day. The obtained melanin was dissolved in an aqueous solution whose pH was adjusted to 8.3 with ammonia water to a concentration of 1.2 g / L. The polarizing film was immersed in the melanin aqueous solution adjusted to 30° C. for 3 minutes in a tense state. Keeping it taut, take out the polarizing film and let it dry.

[0088] The above-mentioned polarizing film was produced according to the method described in Japanese ...

Embodiment 2 and 3

[0091] Under the same conditions as in Example 1, the melanin according to the present invention was produced twice, and polarizing films were produced using the melanin (Examples 2 and 3). Included in Table 1 together with previous results, which were reproducible well.

[0092] [Table 1]

[0093] Table 1

[0094] Example

Embodiment 4

[0096] In the reaction of embodiment 1, except that the concentration is that the catechol of 200g / L is changed into the dopamine (4-(2-aminoethyl)-catechol) that concentration is 139g / L, with implementation The same reaction was carried out in Example 1, and the same polarizing film treatment as in Example 1 was performed with the obtained melanin.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com