AIN crystal and method for growing the same, and AIN crystal substrate

A technology of crystal growth and substrate, applied in the field of AlN crystal substrate and AlN crystal growth, can solve the problems of decreasing the growth rate of AlN crystal and increasing the temperature of AlN crystal growth, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

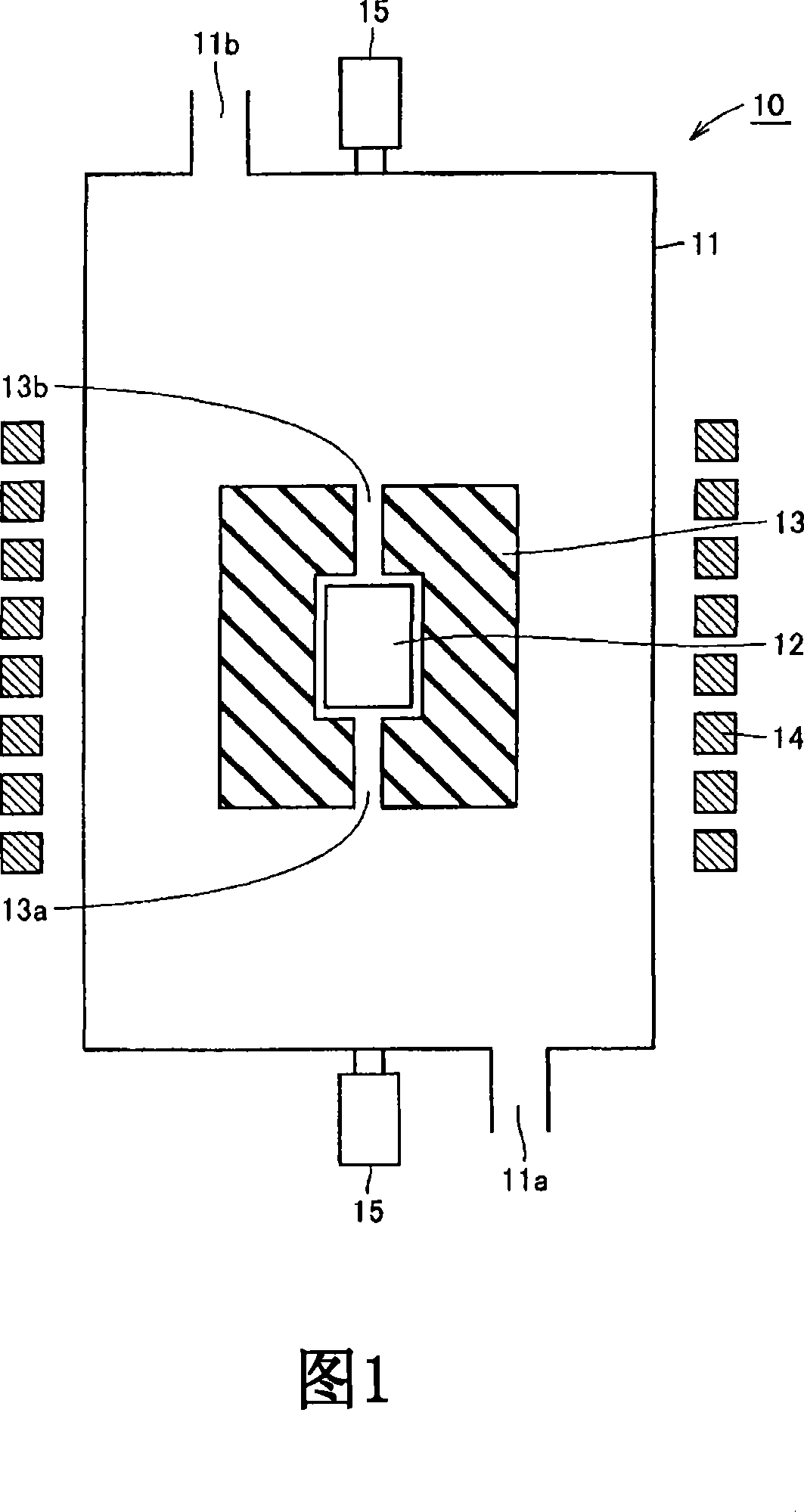

[0034] The present embodiment is characterized in that: referring to FIGS. A carbon-containing gas produced by a reaction between AlN gas sources is supplied to the inside of the crystal growth chamber 24 .

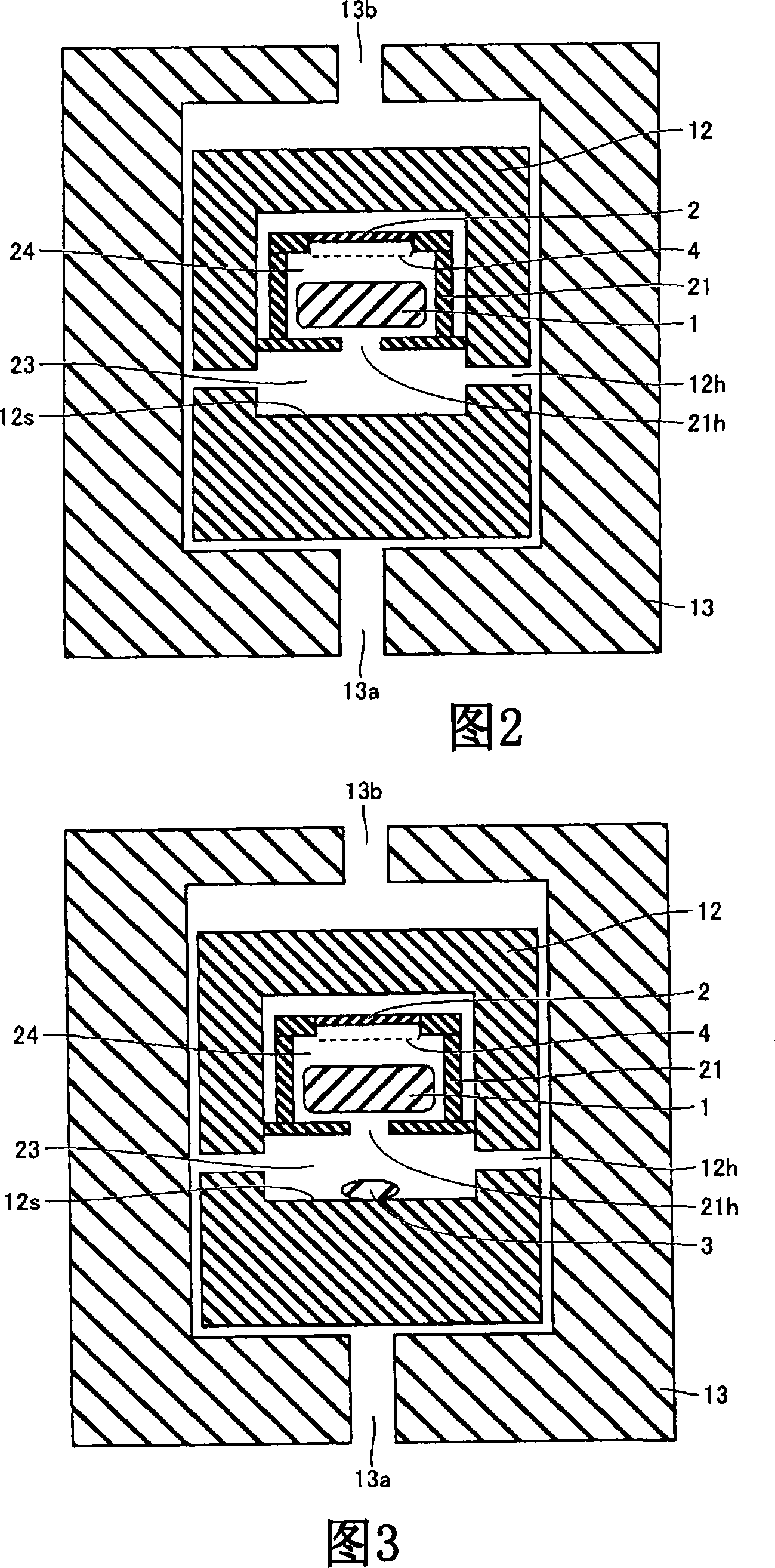

[0035] In the present embodiment, with reference to Fig. 2, the crystal growth chamber 24 with the high temperature resistant material 21 as the wall and the carbon-containing gas production chamber 23 with the high temperature resistant material 21 and the crystal growth vessel 12 as the wall are formed in the crystal growth vessel 12 (graphite crucible) inside. Here, air circulates through crystal growth chamber 24 and carbon-containing gas production chamber 23 via opening portion 21h; Here, the crystal growth chamber 24 communicates with the carbon-containing gas production chamber 23 for ventilation via the opening portion 21h;

[0036] In this embodiment, with reference to FIGS. 1 and 2, the AlN source 1 is placed at one end of the crystal growth chamber 24 where ...

Embodiment approach 2

[0039] The present embodiment is characterized in that: referring to FIGS. 3 CO gas and / or CO gas produced by the reaction between the metal oxide gases produced 2 , is supplied to the inside of the crystal growth chamber 24 as a carbon-containing gas.

[0040] In this embodiment, with reference to Fig. 3, as in Embodiment 1, the crystal growth chamber 24 with the high temperature resistant material 21 as the wall, and the carbon-containing gas production chamber with the high temperature resistant material 21 and the crystal growth vessel 12 as the wall 23, formed in the crystal growth vessel 12 (graphite crucible). Here, air circulates through the crystal growth chamber 24 and the carbon-containing gas production chamber 23 via the opening portion 21h, and circulates through the carbon-containing gas production chamber 23 and the outside of the crystal growth vessel 12 via the opening portions 12h, 13a, 13b. Here, the crystal growth chamber 24 communicates with the carbon-...

Embodiment approach 3

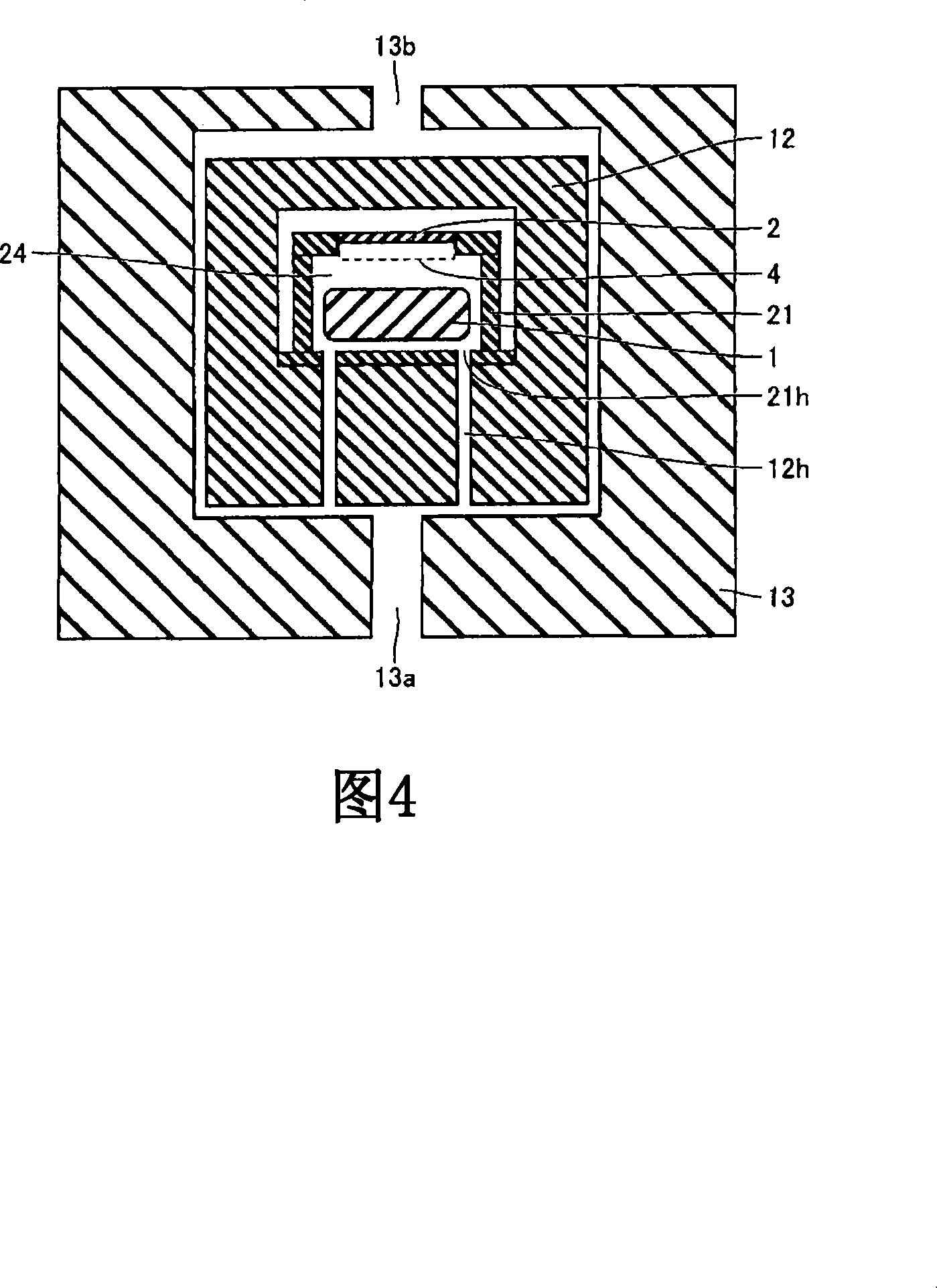

[0045] This embodiment is a mode by which the carbon-containing gas is supplied directly from the outside of the reaction chamber 11 to the inside of the crystal growth chamber 24 in the crystal growth vessel provided in the reaction chamber 11 . Here, in order to control the carbon content in the gas supplied to the inside of the crystal growth chamber 4, a carbon-containing gas is supplied together with a carrier gas. As a carrier gas, use N, which does not react with carbon-containing gases 2 (nitrogen) gas and other gases. In addition, there is no specific limitation on the carbon-containing gas, but from the viewpoint of eliminating regions on the seed substrate 2 where crystals do not grow to efficiently grow large-diameter-span AlN crystals with good crystallinity, it is preferable to use CO gas and / or or CO 2 gas. In this embodiment, referring to FIG. 4 , a crystal growth chamber 24 is formed in a crystal growth vessel 12 (which may not be a graphite crucible) with ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com