Hypergravity purifying method for ammonia nitrogen sewage and hypergravity machine used in the same

A super-heavy machine and super-gravity technology, applied in degassed water/sewage treatment, centrifuged water/sewage treatment, etc., can solve problems such as limited mass transfer efficiency and energy efficiency ratio, threat to biodiversity, ammonia nitrogen pollution, etc. High reduction, improved efficiency, enhanced mass transfer effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

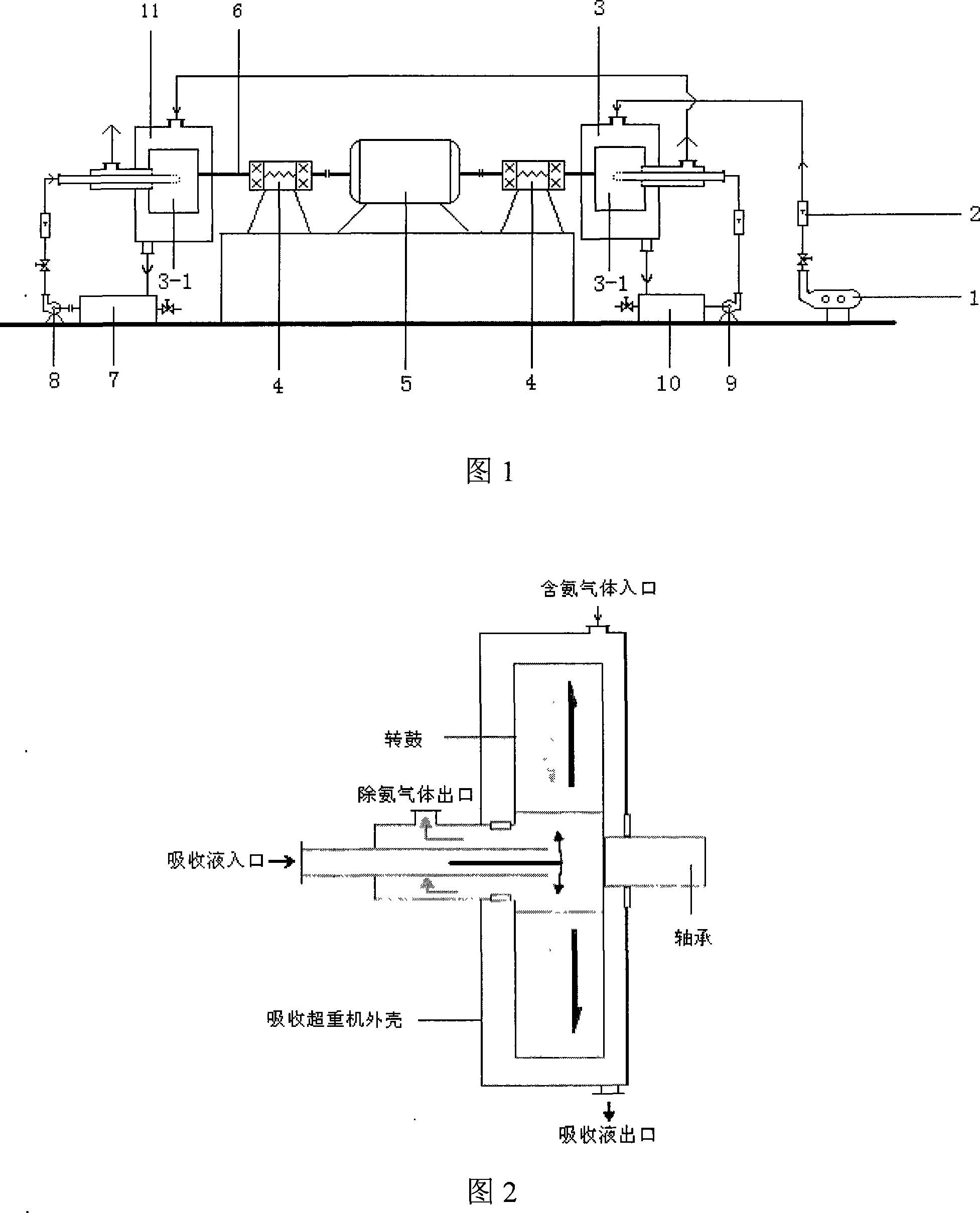

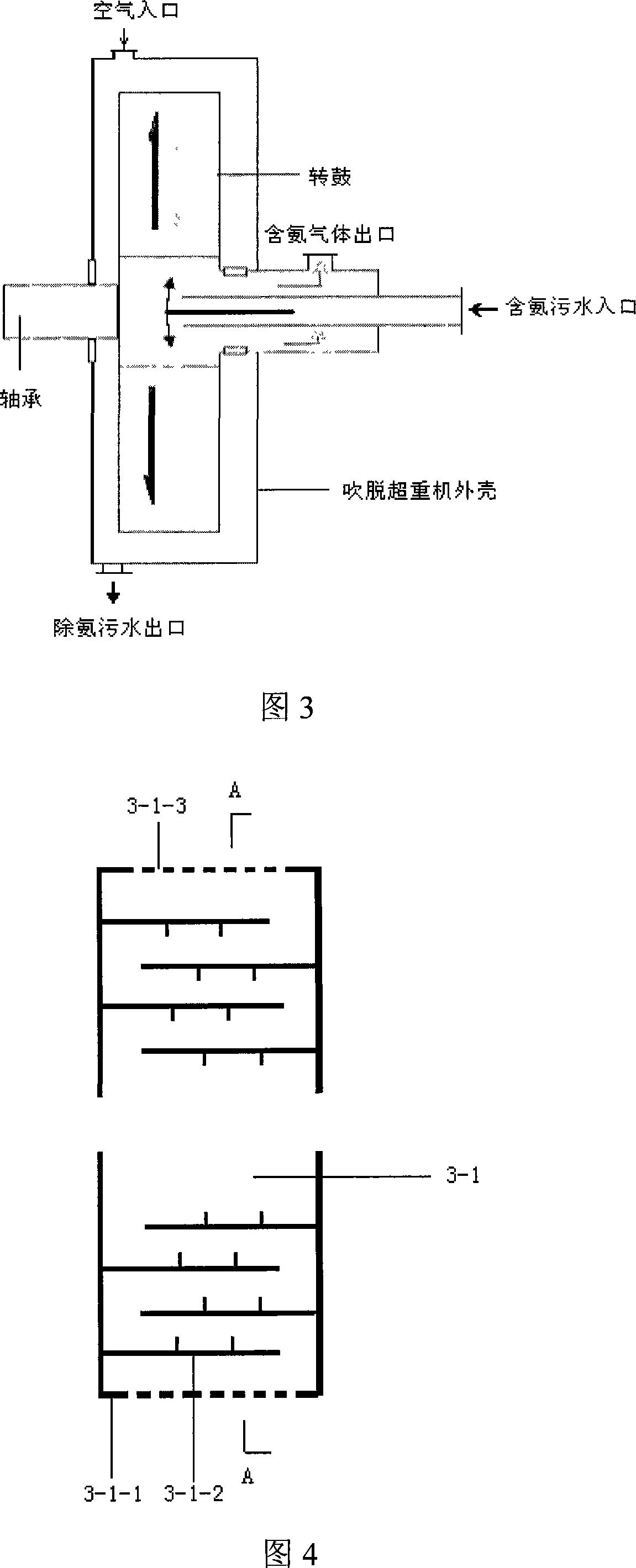

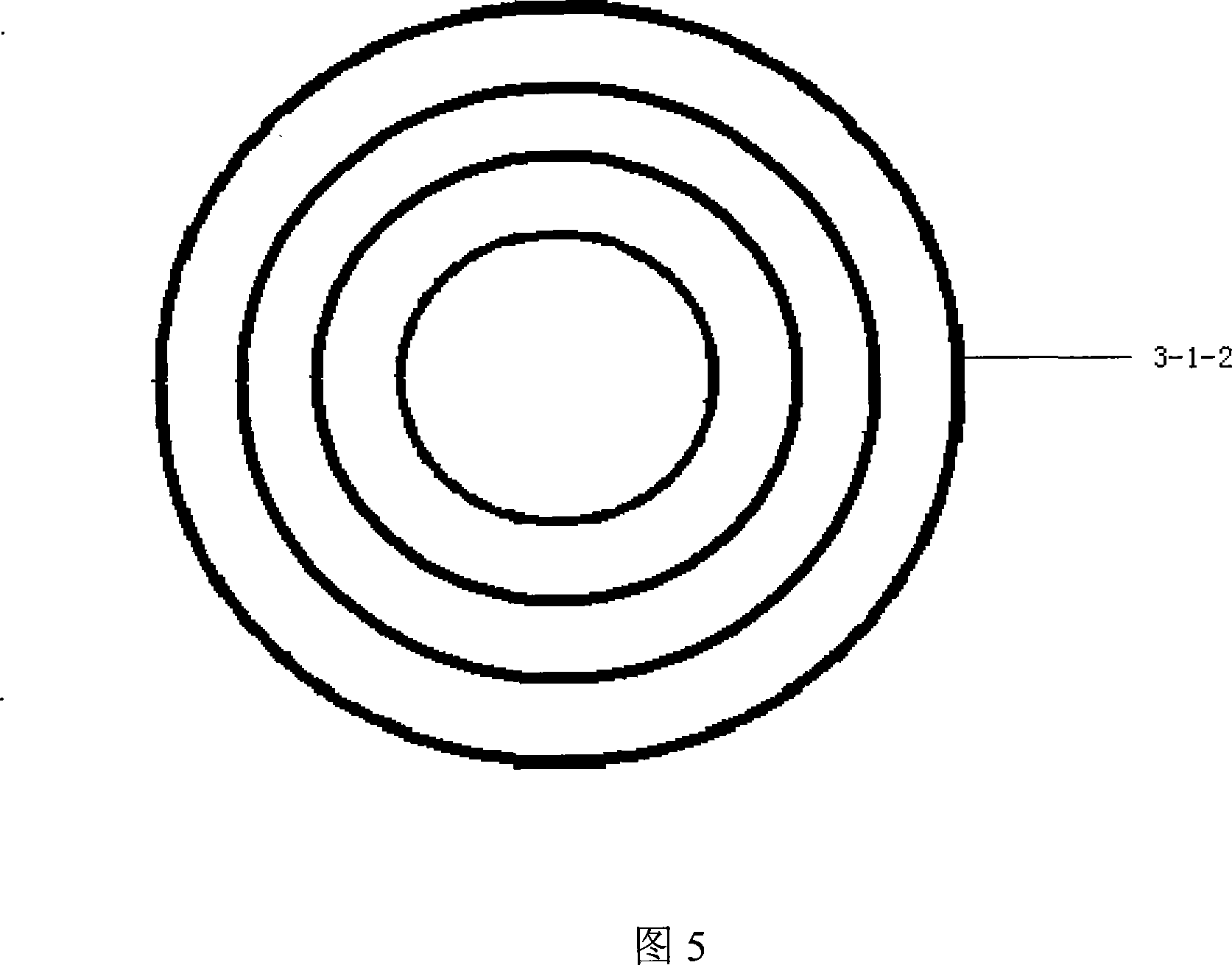

[0024] As shown in Figure 1, and referring to Figure 2 and Figure 3, when using the method of the present invention to purify ammonia nitrogen sewage, at first the sewage pH value is adjusted to 10-11 in the waste water tank 10, and through the water pump 9 and the flow meter 2 The sewage is quantitatively sent to the drum 3-1 in the blowing off overweight machine 3, and at the same time, the Roots blower 1 and the flow meter 2 are used to quantitatively deliver air to the blowing off overweight machine; with the input of sewage, the drum 3-1 At the same time, it rotates under the drive of the motor 5, so that the sewage input into it is thrown out to the outside under the action of centrifugal force until it is thrown out to the drum 3 from the through hole 3-1-3 on the circumferential surface of the drum 3-1. -1 in the inner cavity of the super-heavy machine, and finally discharged from the ammonia removal sewage outlet provided on the outer shell of the super-heavy machine; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com