Motor engine exhaust gas cleaning device

An exhaust purification device and engine technology, applied in exhaust devices, machines/engines, engine components, etc., can solve the problems of reduced effect, poisoning failure, no purification effect, etc., and achieve the effect of excellent characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

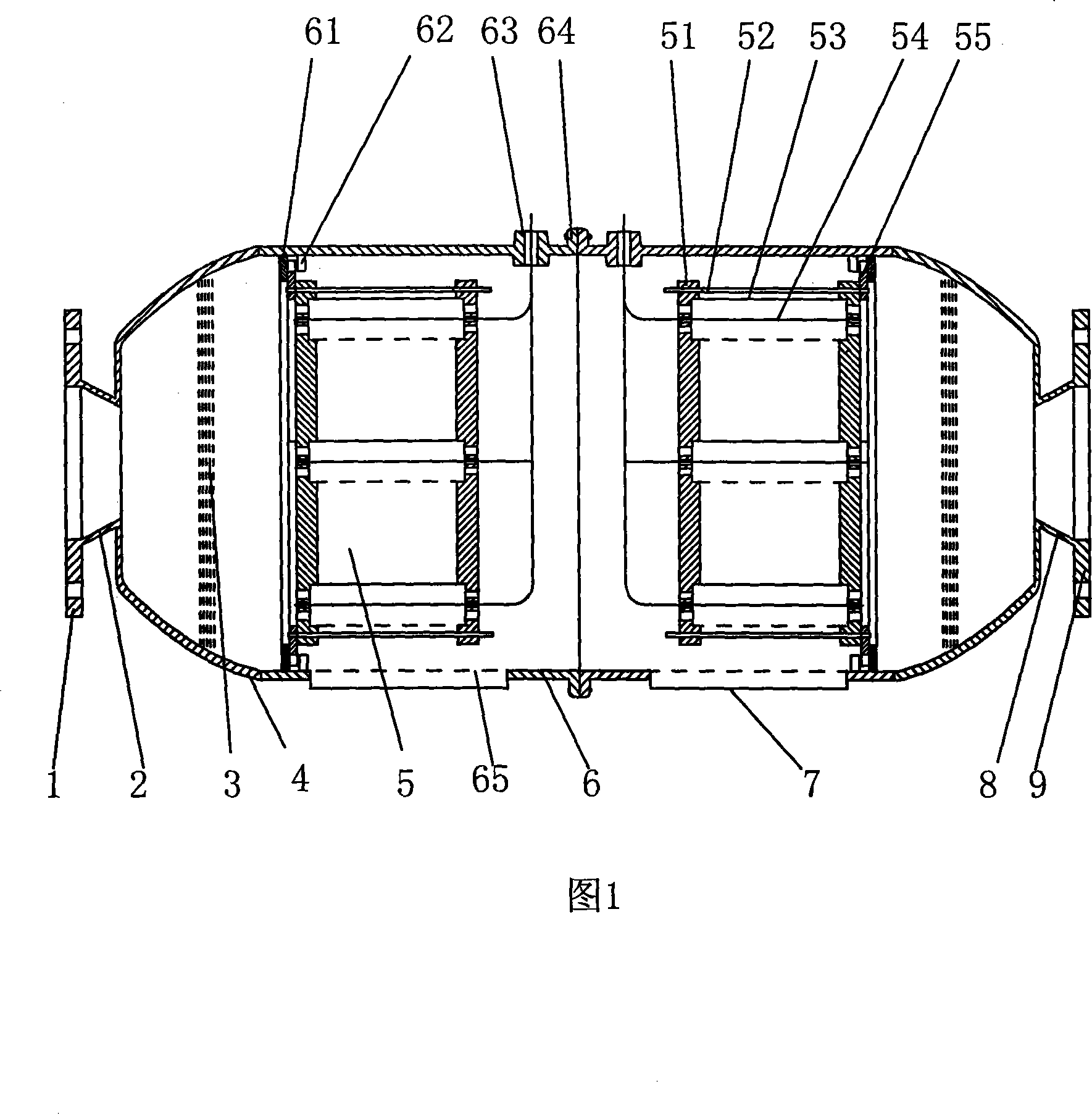

[0039] Embodiment 1: A kind of motor vehicle engine exhaust purification device for Chang'an miniature car.

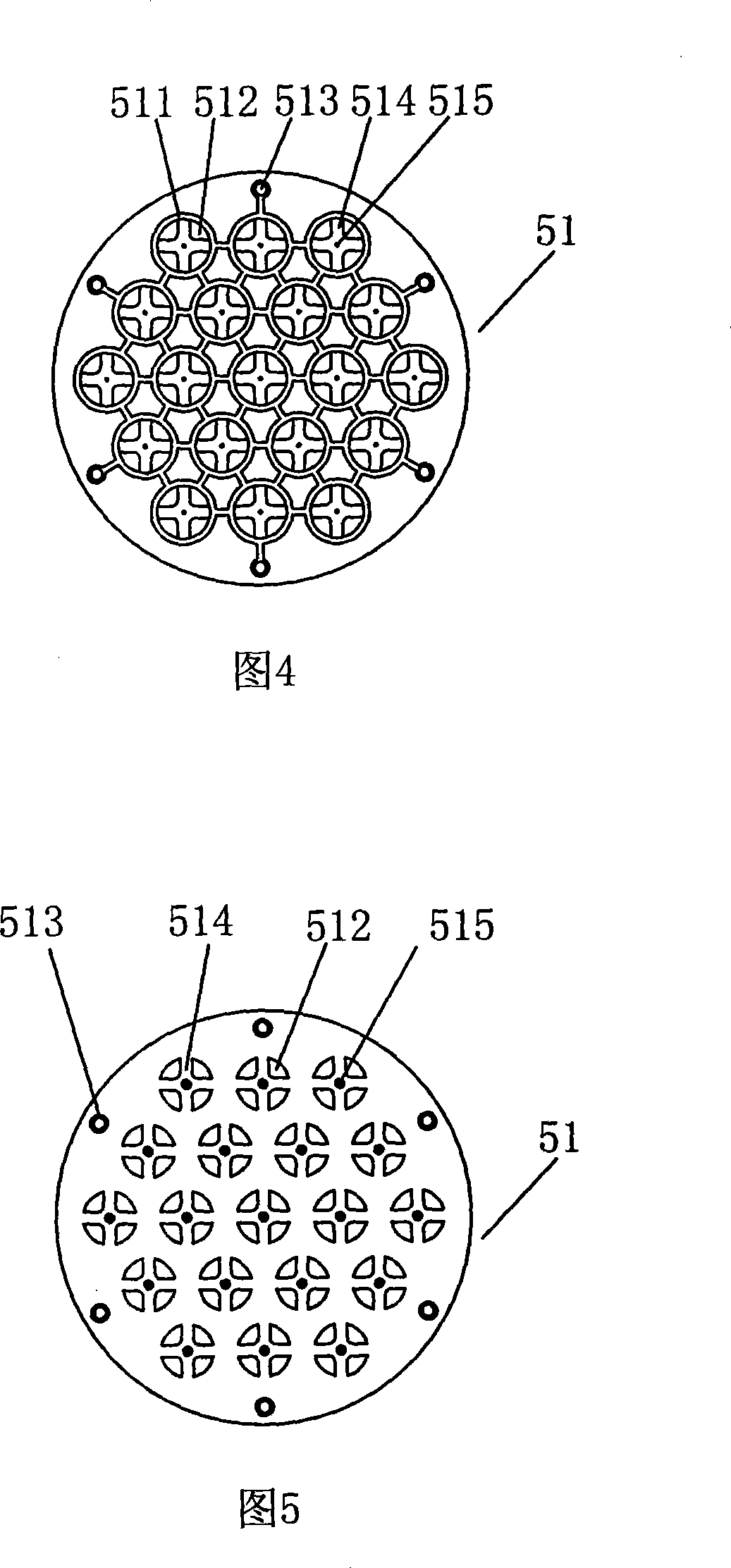

[0040] As shown in Figure 1-11, a motor vehicle engine exhaust purification device, it contains a shell, an air intake pipe 2, an air outlet pipe 8, the shell is a metal shell, and the shell is made of light and heat catalyst to purify the reactor shell 4 Composed of manifold horizontal pulse electrostatic purification reactor shell 6, light and thermal catalyst purification reactor 3 are arranged in light and thermal catalyst purification reactor shell 4, and light and thermal catalyst purification reactor 3 are arranged in manifold horizontal pulse electrostatic purification reactor shell 6. There is a header horizontal pulse electrostatic purification reactor 5, and the light and heat catalyst purification reactor 3 is made of titanium. The header horizontal pulse electrostatic purification reactor 5 is composed of a corona wire 54, an electrode tube 53, and an elect...

Embodiment 2

[0050] Embodiment 2: A kind of motor vehicle engine exhaust purification device for the Ford Focus CAF7201M.

[0051] As shown in Figure 1-11, a motor vehicle engine exhaust purification device, it contains a shell, an air intake pipe 2, an air outlet pipe 8, the shell is a metal shell, and the shell is made of light and heat catalyst to purify the reactor shell 4 Composed of manifold horizontal pulse electrostatic purification reactor shell 6, light and thermal catalyst purification reactor 3 are arranged in light and thermal catalyst purification reactor shell 4, and light and thermal catalyst purification reactor 3 are arranged in manifold horizontal pulse electrostatic purification reactor shell 6. There is a header horizontal pulse electrostatic purification reactor 5, and the light and heat catalyst purification reactor 3 is made of titanium. The header horizontal pulse electrostatic purification reactor 5 is composed of a corona wire 54, an electrode tube 53, and an elec...

Embodiment 3

[0059] Embodiment 3: A motor vehicle engine exhaust purification device for Hongyan truck.

[0060] The basic structure of the motor vehicle engine exhaust purification device of this example is basically the same as that of Embodiment 1, and it is not described in detail. Type pulse electrostatic purification reactor 5, in a set of header horizontal pulse electrostatic purification reactor 5, described electrode tube 53 is 26, each length 160mm, internal diameter is 36mm.

[0061] The Hongyan truck used in this example is a heavy-duty vehicle. After using the vehicle engine exhaust purification device, it has been tested and has a remarkable effect.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com