Nano sheet hydroxyapatite and glutin composite material and preparation

A hydroxyapatite and nano-sheet technology, applied in the field of biomedical materials, can solve the problems of easy agglomeration, difficult to disperse, limit the mechanical properties of hydroxyapatite composite materials, etc. applied effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Add 1.0 g of layered hydroxyapatite powder with an interlayer distance of 3.1 nm into a beaker (see CN101058416 for the preparation method), and add a small amount of deionized water. Stir at room temperature for 3 hours to obtain a uniformly dispersed hydroxyapatite emulsion. Weigh 2 g of gelatin particles to prepare a gelatin transparent solution with a concentration of 6%. The gelatin solution was first added into a three-neck flask, and the temperature was raised to 73° C. using a constant temperature magnetic stirring heating mantle. Under stirring, the above-mentioned hydroxyapatite emulsion was added to the gelatin solution. The reaction was stirred at 73 °C for 4 h. Pour the reaction product into an evaporating dish. Vacuum dry at 70°C for 4h.

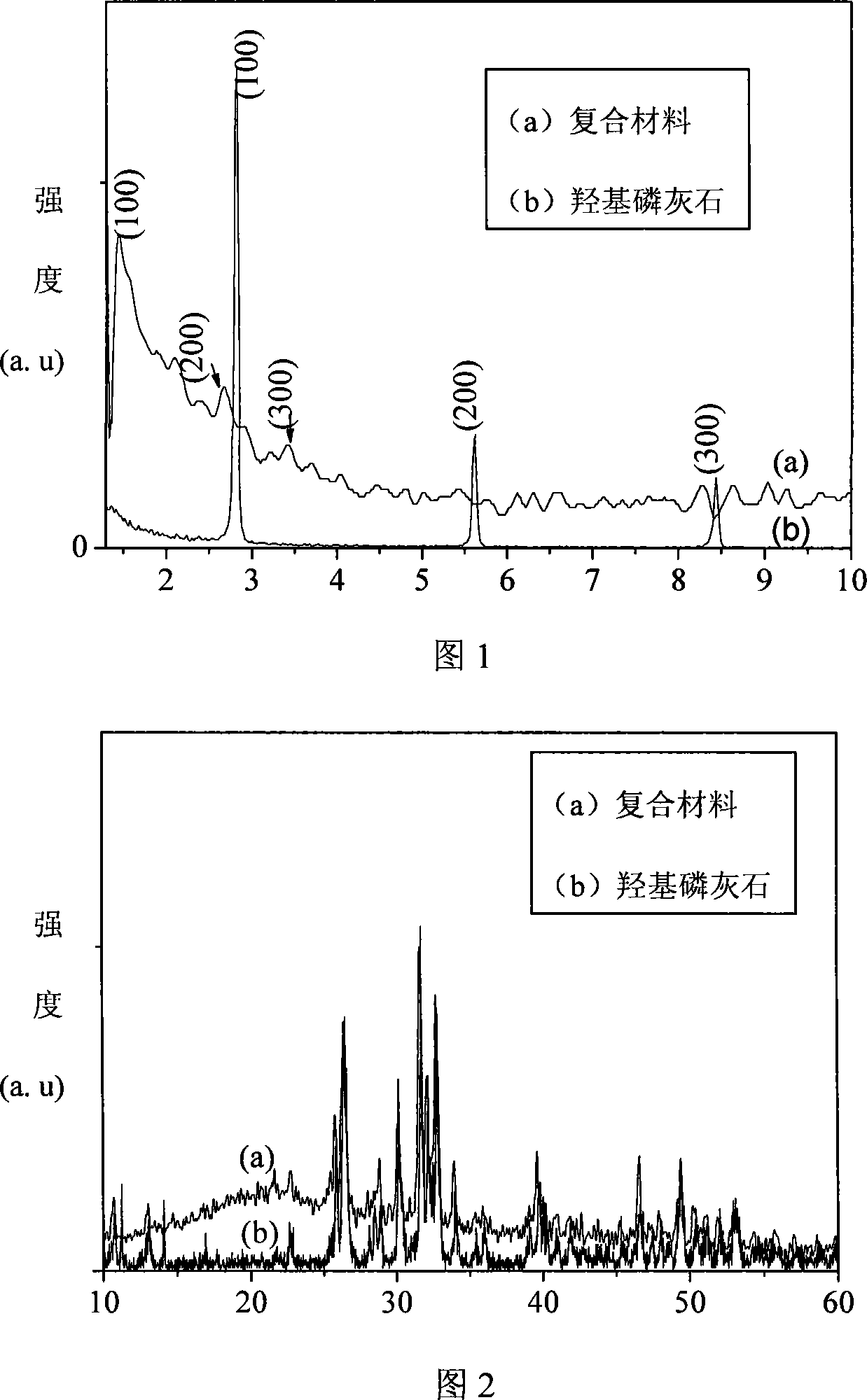

[0018] Grind the obtained product into powder and pass through a 120-mesh sieve. Carry out XRD test, Fig. 1 is X-ray small-angle diffraction pattern, Fig. 2 is X-ray large-angle diffraction pattern.

[0019] Test r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com