Casting parts thermal insulation pit

A technology for pits and castings, applied to furnaces, vertical furnaces, lighting and heating equipment, etc., to achieve the effects of ensuring cooling speed and temperature uniformity, wide application range, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

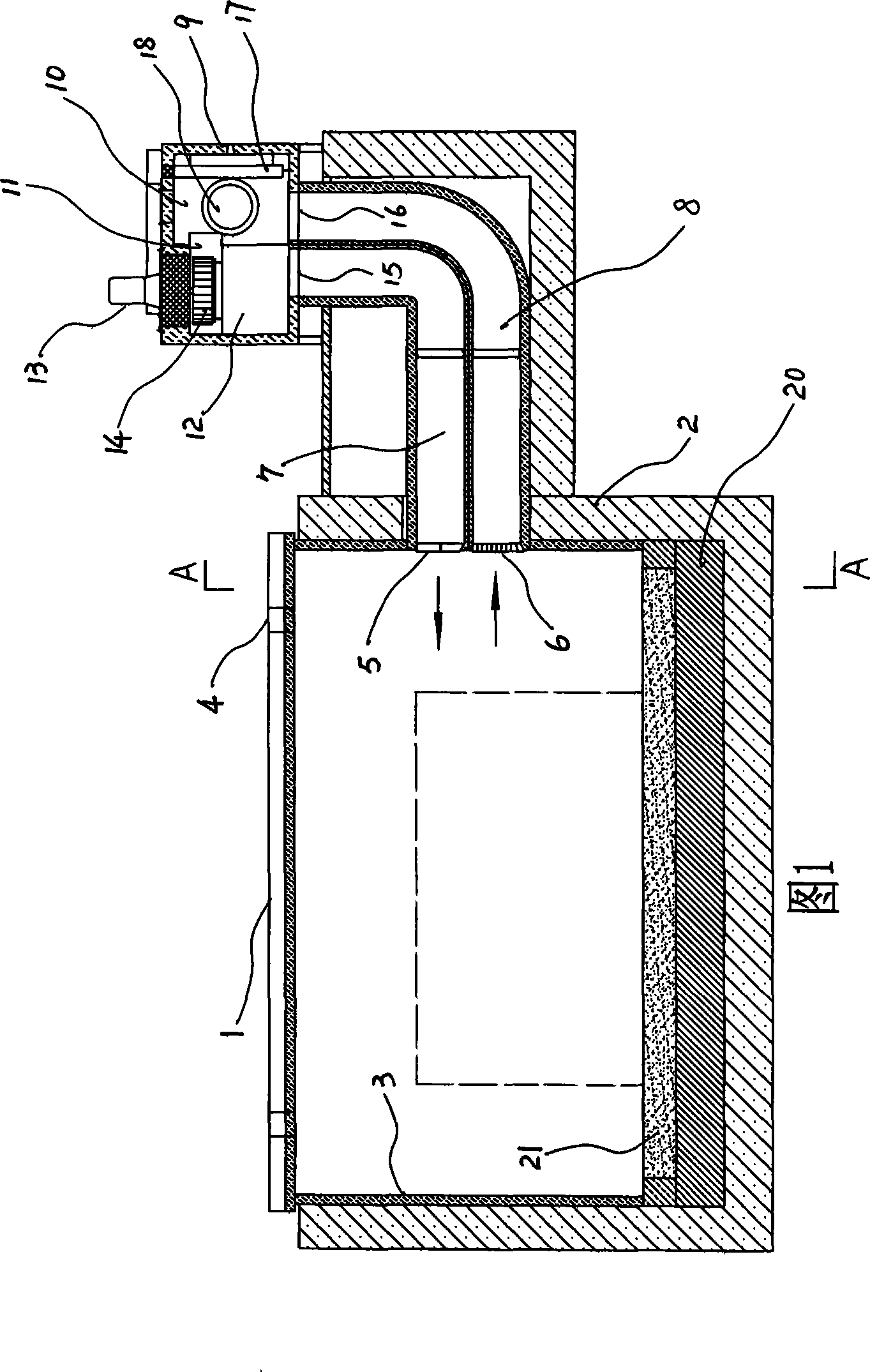

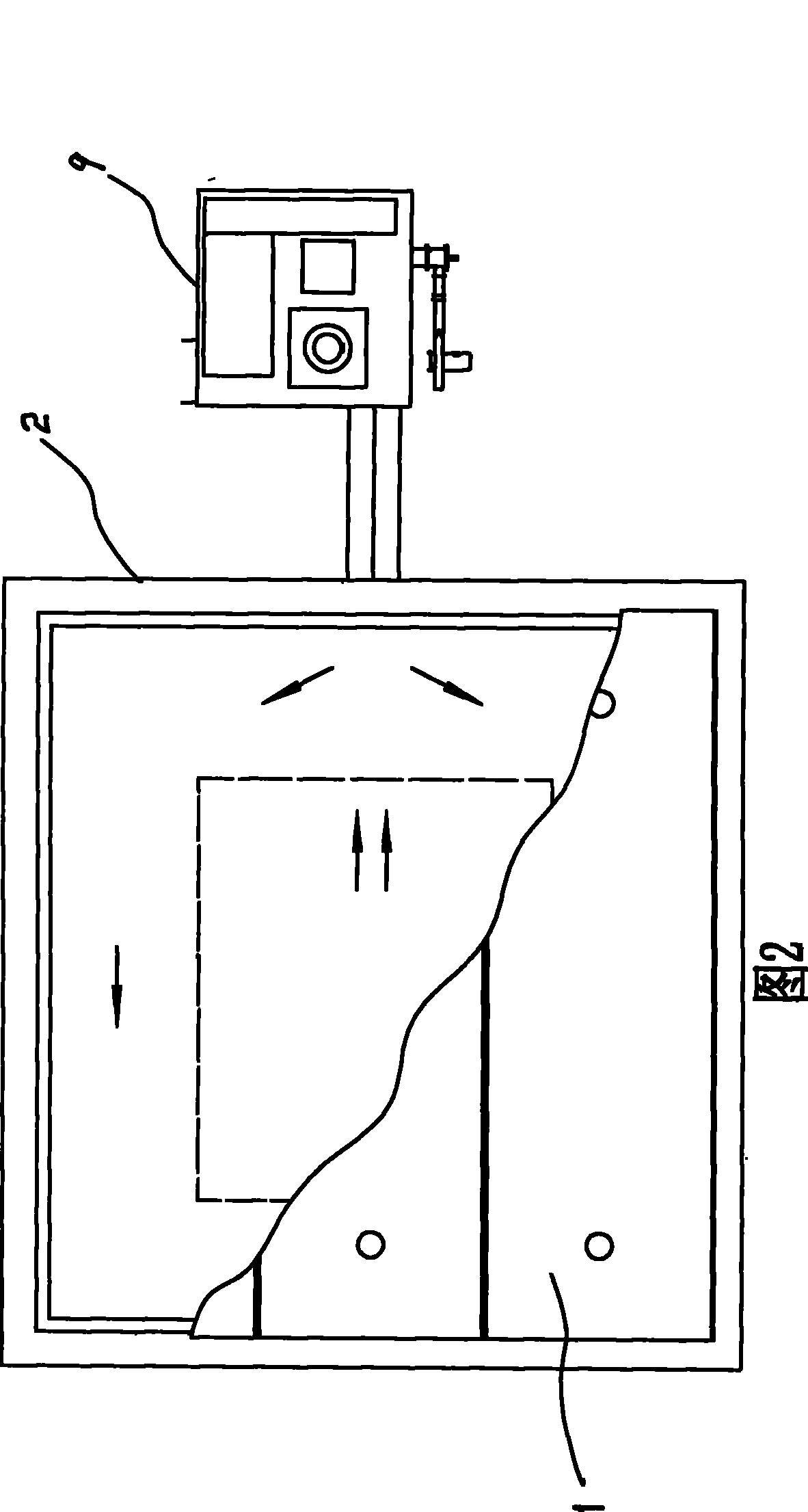

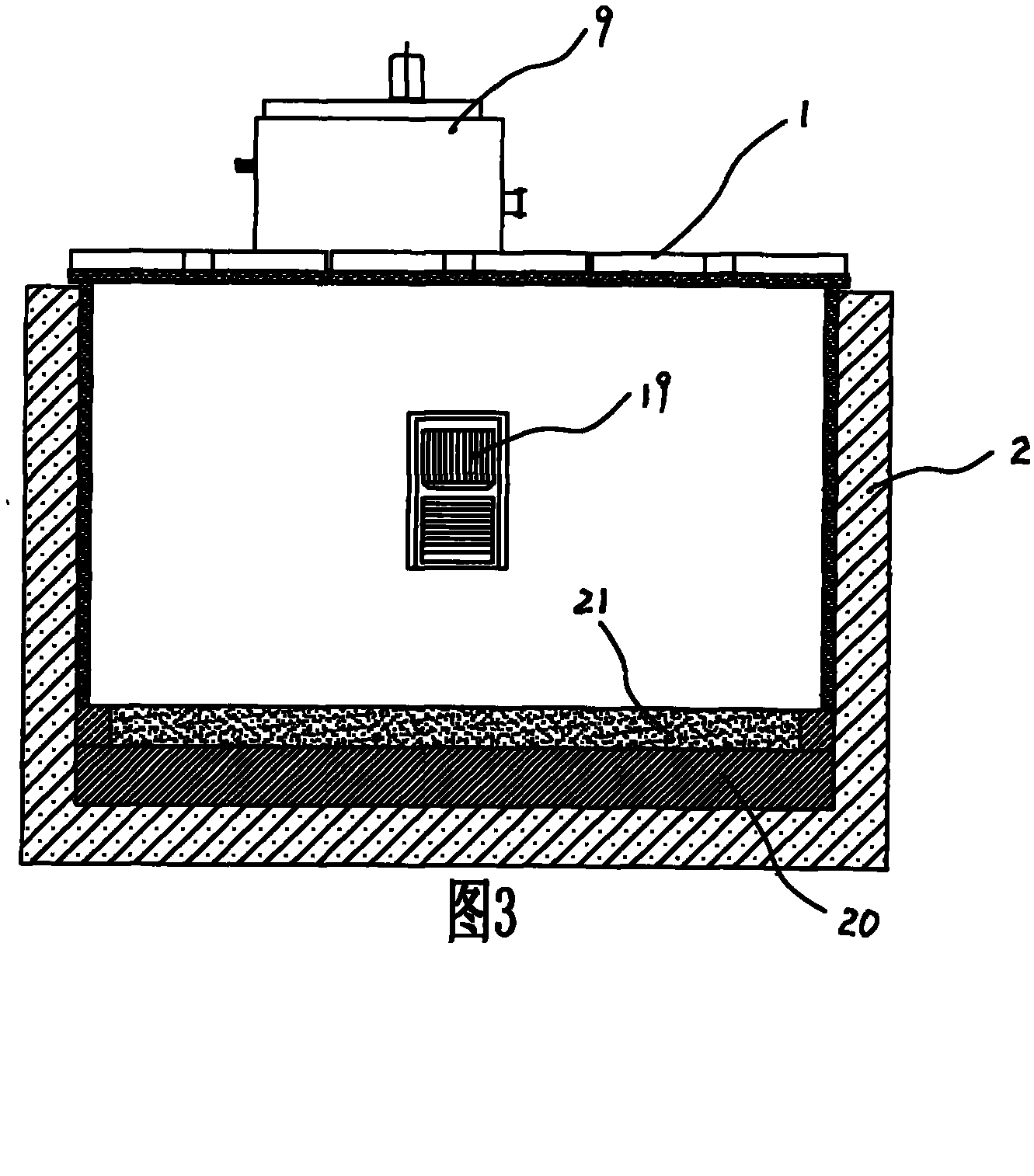

[0015] As shown in Figures 1, 2, and 3, the casting insulation pit according to the present invention includes a pit body 2 built by concrete with a split movable cover plate 1, and on the bottom wall of the pit body 2 A load-bearing heat-insulating layer constructed of heat-insulating floor tiles 20 and a sandy soil layer 21 is laid, and a refractory fiber heat-insulating layer 3 is arranged on the side wall; a plurality of vent holes 4 with covers are opened on the movable cover plate 1, On the side wall of the pit body 2, air supply and return air outlets 5, 6 are provided, and the air supply and return air outlets 5, 6 communicate with the circulating hot air device 9 through the air supply and return air pipes 7, 8. The circulating hot air device 9 is formed by communicating with a negative pressure chamber 10, a circulating air chamber 11 and a positive pressure chamber 12, and the blades 14 of the circulating fan 13 are arranged in the circulating air chamber 11; The ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com