Diesel engine base, engine base frame automatically welding workstation

A technology of automatic welding and machine frame, which is applied in the direction of welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of high energy consumption, workers' health, unfavorable quality control of weldments, etc., achieve reasonable structure and improve welding efficiency , good working performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

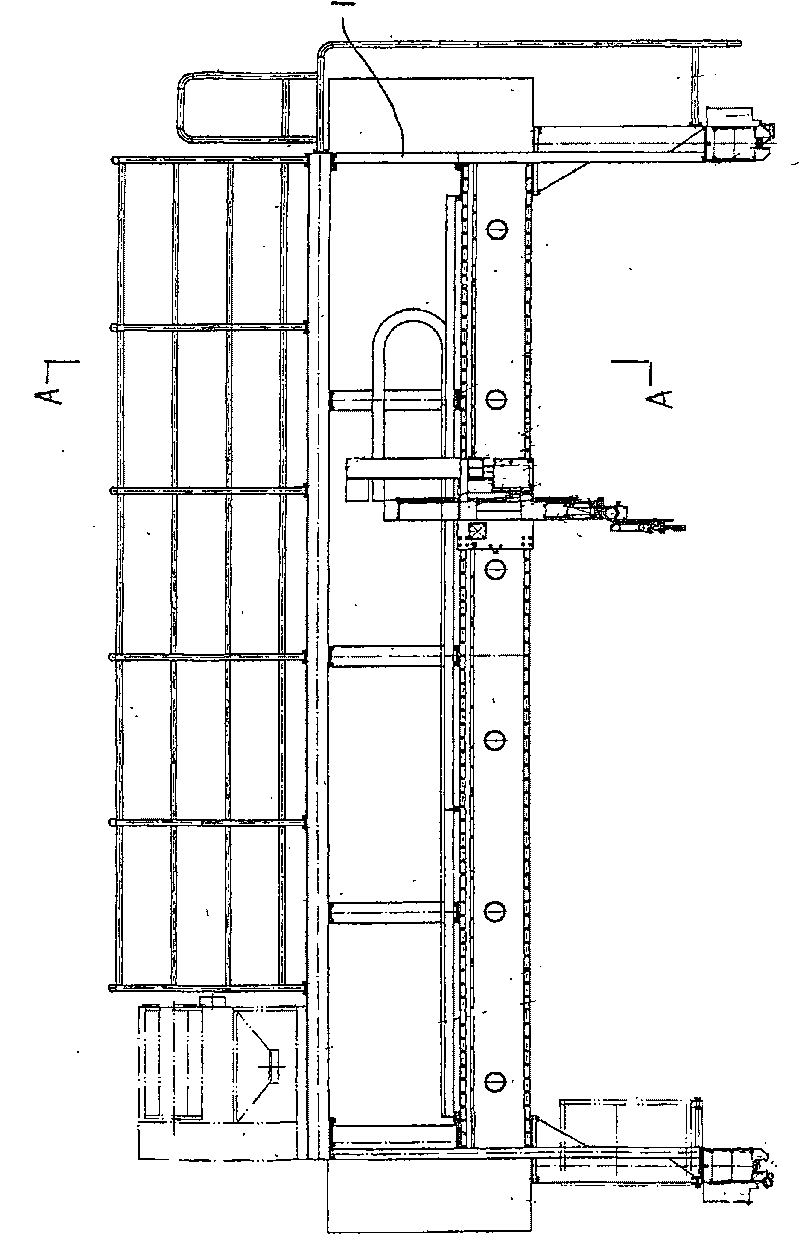

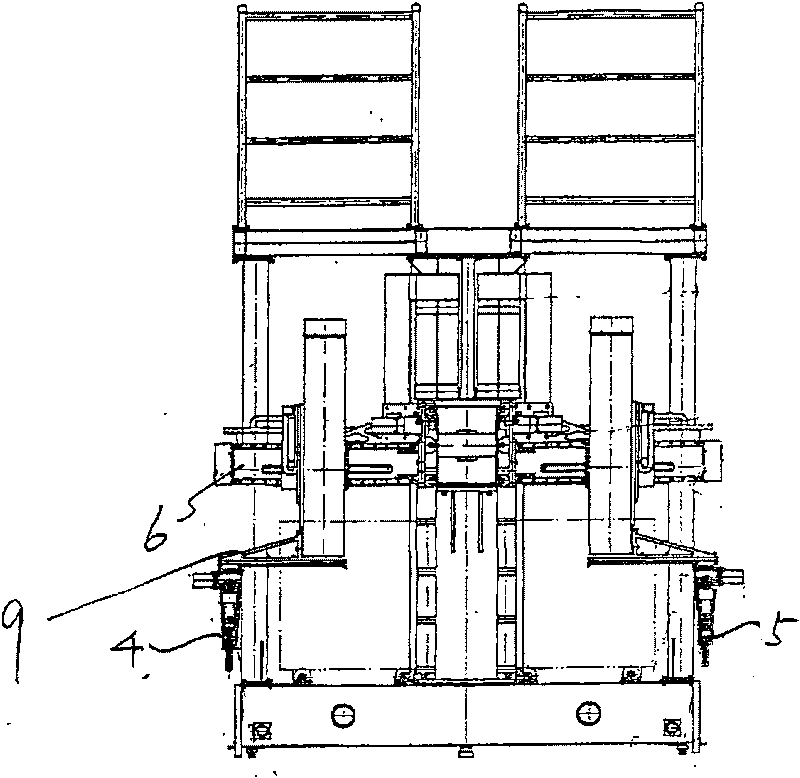

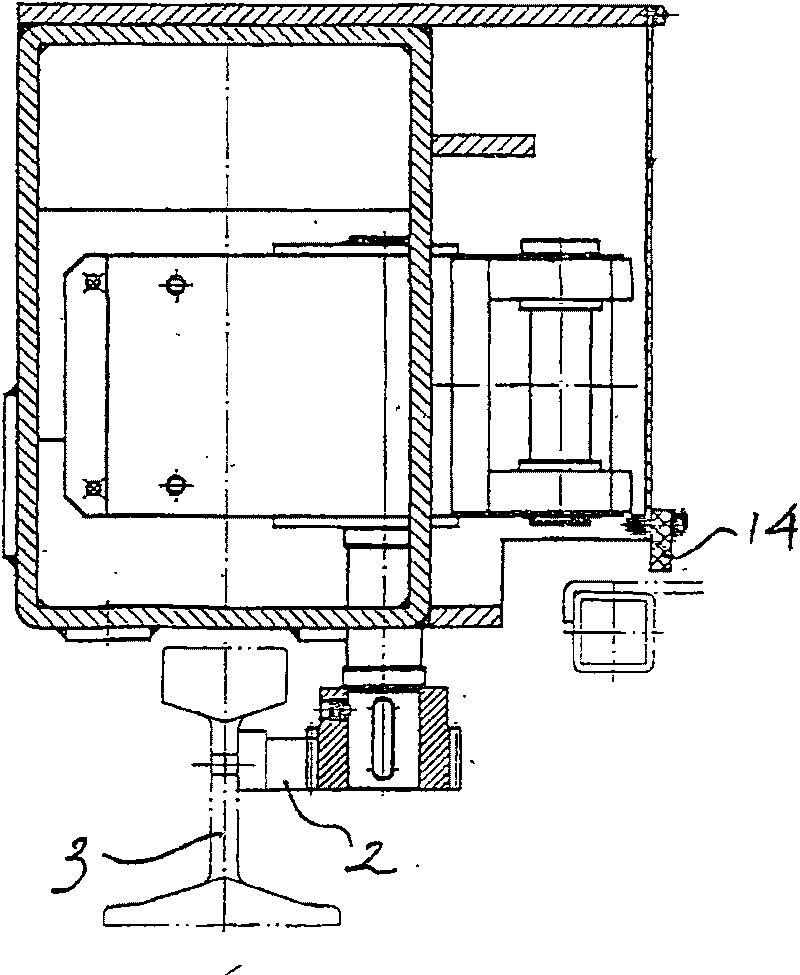

[0014] An automatic welding workstation for diesel engine frame and frame, comprising a door frame 1, which is mounted on a guide rail 3 through a walking mechanism 2, and two sides of the door frame beam are provided with welding torch mechanisms 4, 5 that move on the rail of the beam , Each welding torch mechanism includes a cross arm 6 with a moving rail, a horizontal moving block 7 that can move horizontally along the horizontal arm moving rail is set on the cross arm 6, a longitudinal rail is set on the horizontal moving block 7, a lifting arm 8 and the The vertical guide rail is connected up and down, the lower end of the lifting arm 8 is connected with the triangular supporting welding torch connecting frame 9, the lower part of the triangular supporting welding torch connecting frame 9 is equipped with an oscillator 11 driven by a servo motor 10, and the end of the oscillator 11 is connected to a cooling automatic welding gun 12 And the laser welding seam tracking sensor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com