Water-absorbing polymer structure having great ammonia-binding capacity

A technology of water-absorbing polymers and structures, applied in fertilizer mixtures, absorbent pads, animal repellents, etc., can solve problems such as reduced swelling properties, temperature sensitivity, and low polymer network ionicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

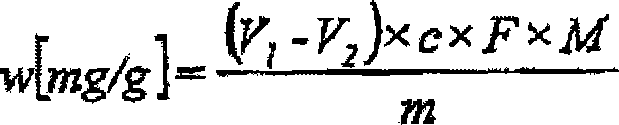

Method used

Image

Examples

Embodiment Construction

[0141] 1. Preparation of untreated water-absorbing polymer structures (process step i))

[0142] From 2,400g of acrylic acid, 1,332.2g of NaOH (50% concentration), 4,057.4g of deionized water, 2.14g of polyethylene glycol-300-diacrylate (active ingredient content of 78.4wt.%), 6.92g Monoallyl polyethylene glycol-450-monoacrylate (active ingredient content is 72.8wt.%) and 65.36g of polyethylene glycol-750-monomethacrylate methyl ether (active ingredient content is 73.4 wt.%) monomer solution composed of nitrogen to remove dissolved oxygen, and cooled to the initial temperature of 4 ° C. After reaching the starting temperature, the initiator solution (2.4 g sodium persulfate in 77.6 g H2O, 0.56 g 30% hydrogen peroxide solution in 15.44 g H2O, and 0.12 g ascorbic acid in 39.88 g H2O) was added. After the final temperature reached about 100°C, the gel thus obtained was pulverized using a meat grinder and dried in a drying oven at 150°C for 2 hours. The dried polymer was coarsel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com