Technique for preparing biological diesel oil by utilizing waste carclazyte

A technology of biodiesel and process method, which is applied in the field of biodiesel preparation, can solve problems such as complex process, large waste liquid discharge, poor reaction mass transfer, etc., and achieve the effects of improving economic benefits, solving environmental problems, and increasing development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0007] The invention adopts chemical engineering principles such as oil extraction and esterification / ester exchange to efficiently recover oil from waste clay and process it into biodiesel.

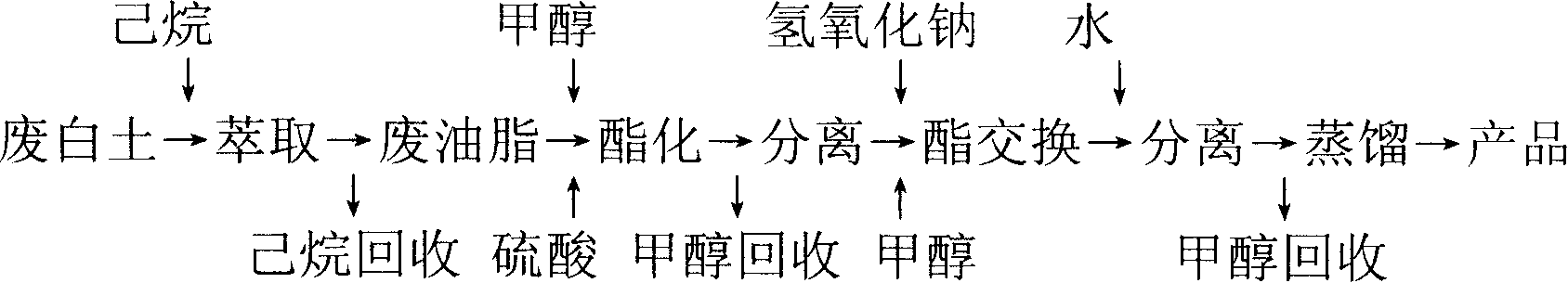

[0008] The flow process of production technique of the present invention sees figure 1 .

[0009] The use of white clay in the oil refining process is for the decolorization of oil. It mainly uses the two processes of physical adsorption and chemical adsorption of white clay to remove pigments and soaps in oil and impurities such as phospholipids and metal derivatives. When white clay absorbs these impurities, it also inevitably absorbs a large amount of oil, which reduces the yield of oil.

[0010] The main chemical composition of the waste clay after decolorization is: SiO 2 、Al 2 o 3 , Fe 2 o 3 , CaO, MgO, Na 2 O, K 2 O, neutral oils, non-hydratable phospholipids, natural pigments, fatty acids and vitamins, etc., generally dark brown semi-solid matter containing oil and other ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com