Method for complexing composite starch sizing agent

A technology of compound starch and sizing agent, applied in the direction of adding water repellent, can solve the problem of difficult to meet the requirements of water repellency, and achieve the effects of excellent water repellency, easy industrialization and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] A compound method for a composite starch sizing agent, comprising the steps of: preparing an aqueous solution of cornstarch with a weight concentration of 10%, heating and gelatinizing in water at 90° C. to obtain a clear cornstarch solution; then adding 10% (accounting for the weight of the starch) percent) of stearic acid (C18 fatty acid), while adjusting the pH to 8, continuing to stir and keep warm at 90°C for at least 30 minutes, so that the fatty acid is fully dissolved, and fully mixed with cornstarch to obtain a composite cornstarch sizing agent.

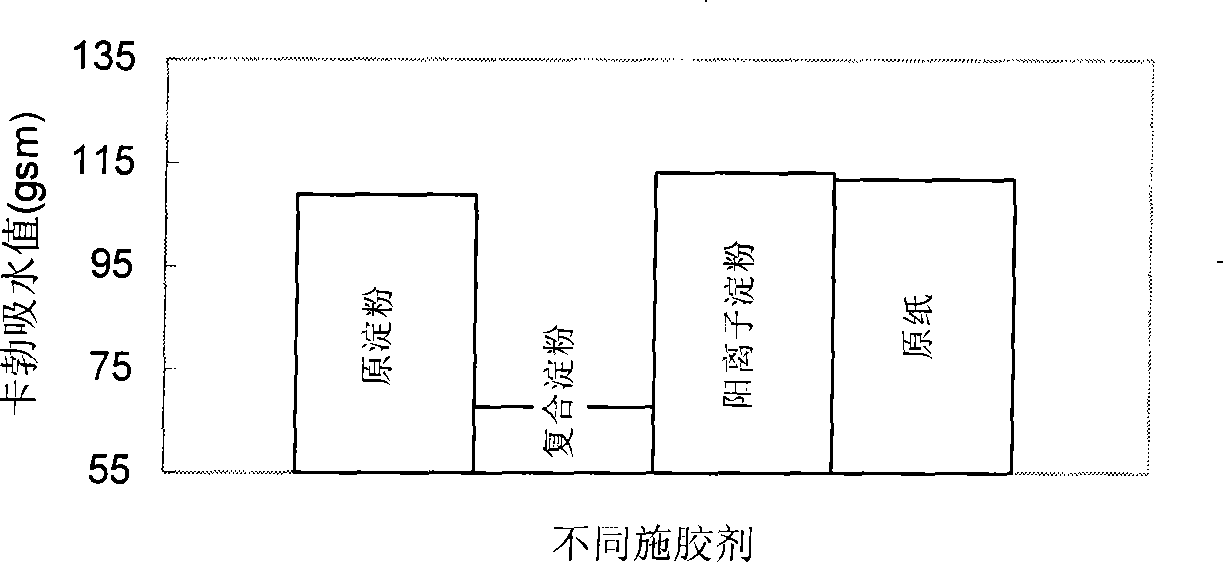

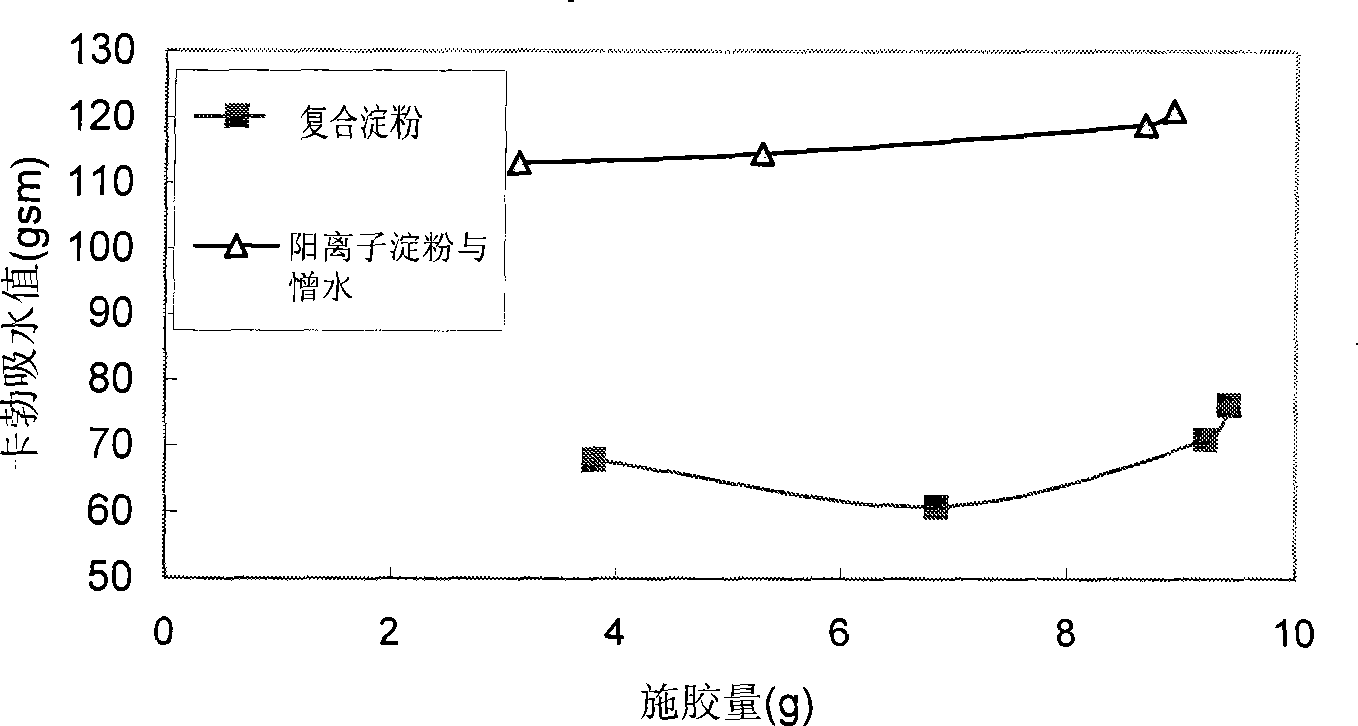

[0017] The above-mentioned composite cornstarch sizing agent 10% concentration (weight concentration) is directly sizing on the base paper of quantitative 100GSM, base paper Cobb (Carber water absorption value, paper sizing degree) water absorption value 1 minute 112GSM, after surface sizing 4GSM, Cobb water absorption value is only 60GSM in 1 minute. After sizing 4GSM on the surface of the original starch (uncompound...

Embodiment 2

[0019] A compound method for a composite starch sizing agent, comprising the steps of: preparing an aqueous tapioca starch solution with a weight concentration of 1%, heating and gelatinizing in water at 100° C. to obtain a clear tapioca starch solution; then adding 1% (accounting for the weight of the starch) percentage) of caprylic acid (C8 fatty acid), while adjusting the pH to 11, continue to stir and keep warm at 100°C for at least 30 minutes, so that the fatty acid is fully dissolved, and fully mixed with tapioca starch to obtain a composite tapioca starch sizing agent.

Embodiment 3

[0021] A compound method of a composite starch sizing agent, comprising the steps of: preparing an aqueous solution of potato starch with a weight concentration of 20%, heating and gelatinizing in water at 95° C. to obtain a clear potato starch solution; then adding 40% (accounting for the weight of the starch) percent) of palmitic acid (C12 fatty acid), adjust the pH to 9 at the same time, continue to stir and keep warm at 95°C for at least 30 minutes, so that the fatty acid is fully dissolved, and fully mixed with potato starch to obtain a composite potato starch sizing agent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com