Pulse type ultraluminescence method sulphur ¿Cmeasuring dedicated quartz tube

A fluorescence method, pulsed technology, applied in fluorescence/phosphorescence, test sample preparation, material excitation analysis, etc., can solve the problems of small sample injection volume, short residence time, affecting the accuracy of sulfur measurement, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

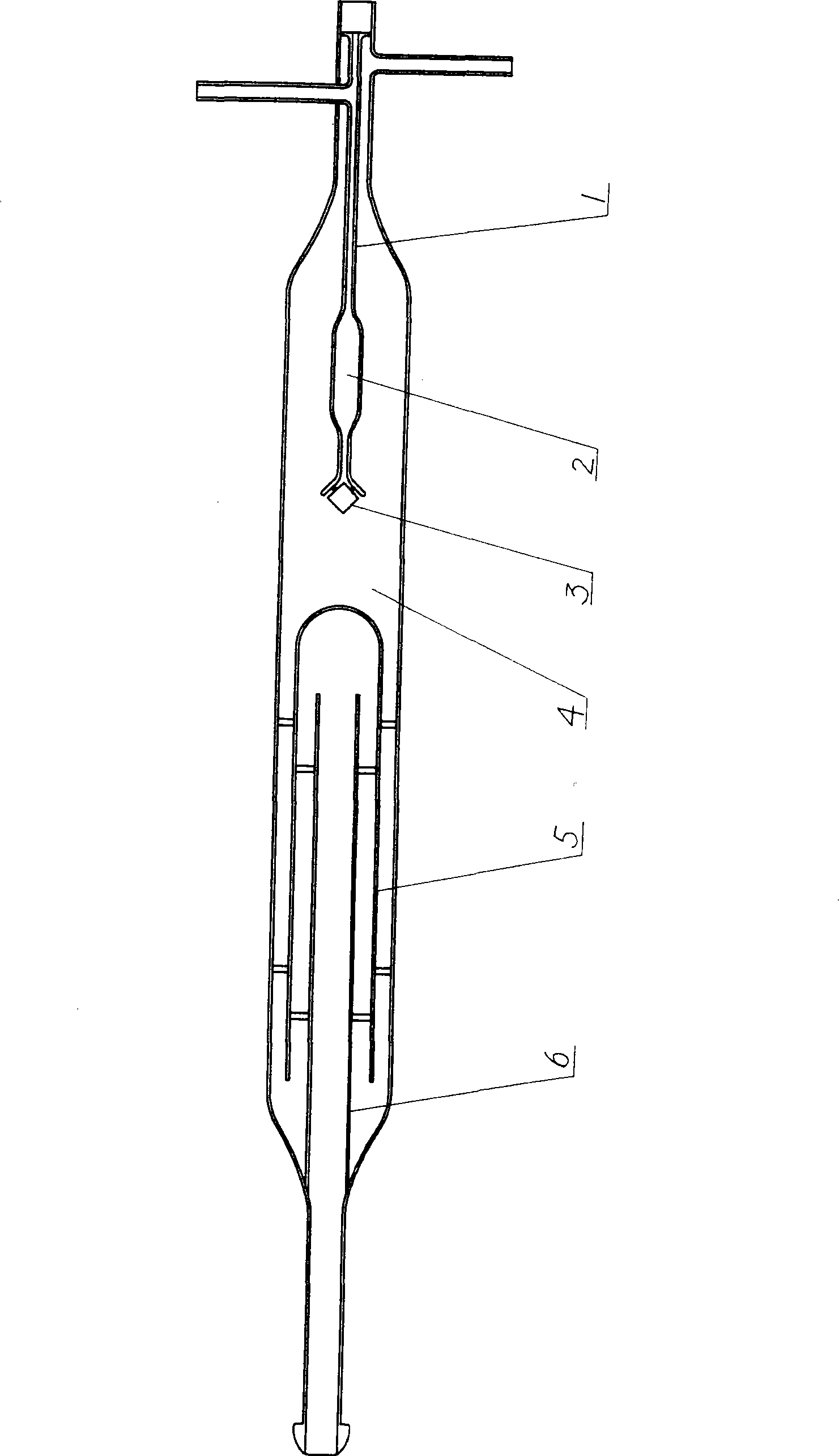

[0008] Referring to the attached picture, the special quartz tube for sulfur measurement by pulsed ultraviolet fluorescence method is carefully fired from high-quality quartz glass. The middle part of the quartz tube is the combustion chamber 4, and the two ends of the combustion chamber are respectively equipped with a sample inlet tube 1 and a sample outlet tube 6, and there are oxygen and carrier gas inlets. The vaporization chamber 2 in the combustion chamber is provided with a buffer tube 5 coaxial with the combustion chamber near the sample outlet tube. The buffer tube is closed at one end facing the sample tube and opened at the other end. In the tube, there are gaps between the inner and outer walls of the buffer tube, the outer wall of the sample tube, and the inner wall of the combustion chamber. The outlet of the vaporization chamber is trumpet-shaped, with a tapered stopper 3 in the middle, forming a tapered annular channel.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com