Extremely-high concentration multi-species heavy metal waste liquid treatment method and apparatus

A waste liquid treatment and heavy metal technology, which is applied in the field of waste liquid treatment, waste water and waste liquid treatment, can solve the problems of difficulty in reaching the standard and large limitations, and achieve the effects of simple operation procedures, reduced operating costs, and good effluent quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

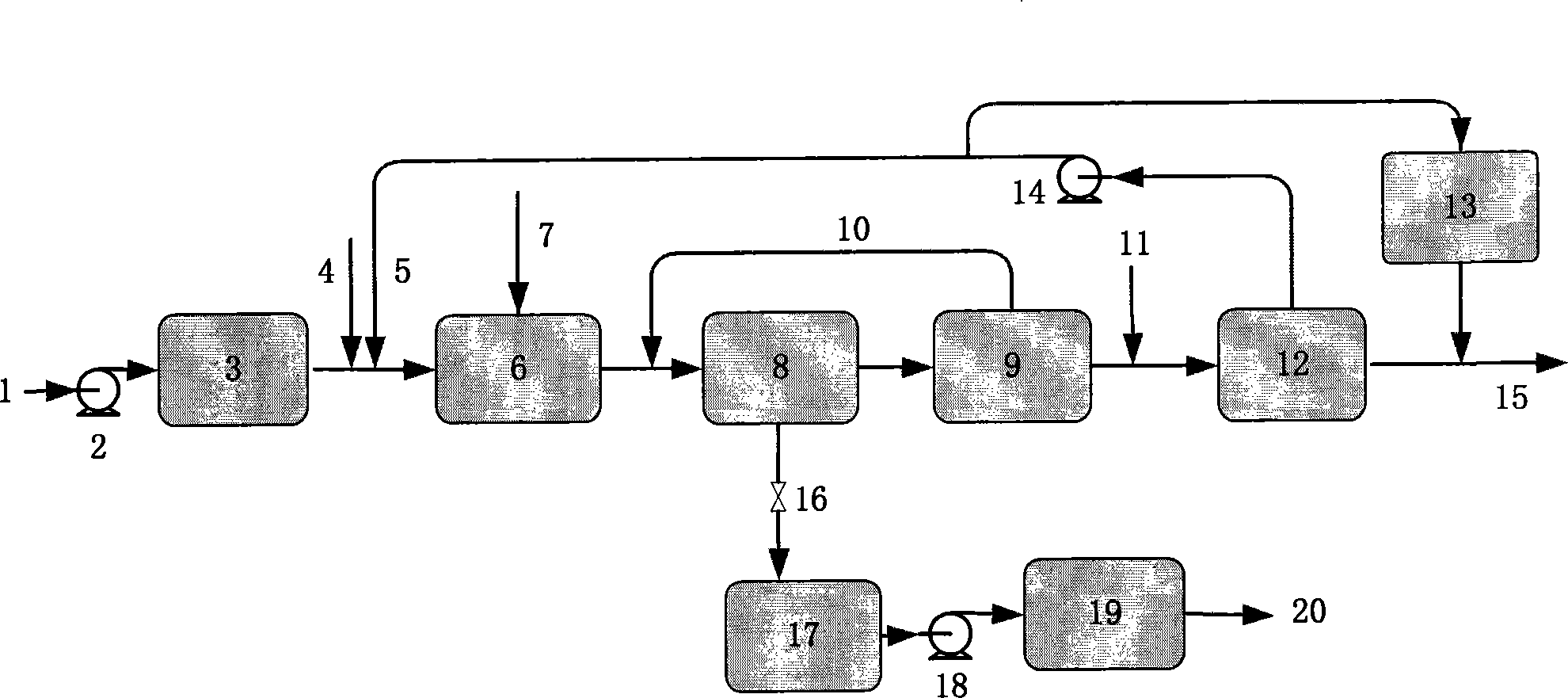

Method used

Image

Examples

Embodiment 1

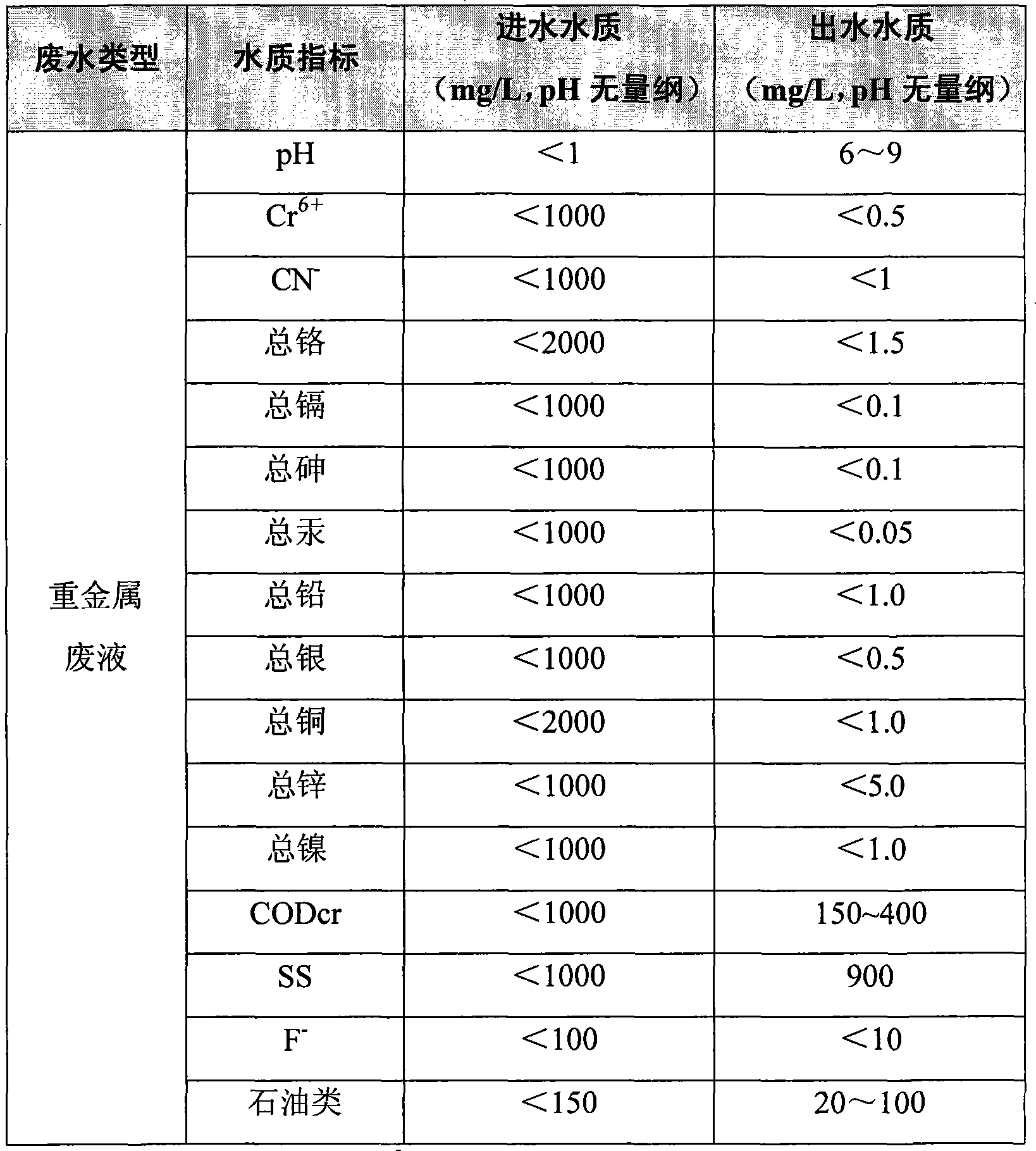

[0025] Embodiment 1: In the physical and chemical workshop of Beijing Dangerous Wastewater Disposal Center, heavy metal waste liquid mixtures from different factories, electroplating plants and laboratories are used to treat the waste water by the method and device of the present invention, with a treatment capacity of 4500t / y ( 15.0t / d), the specific influent water quality and effluent water quality are shown in Table 1.

[0026] Table 1 Influent and effluent water quality of heavy metal waste liquid

[0027]

Embodiment 2

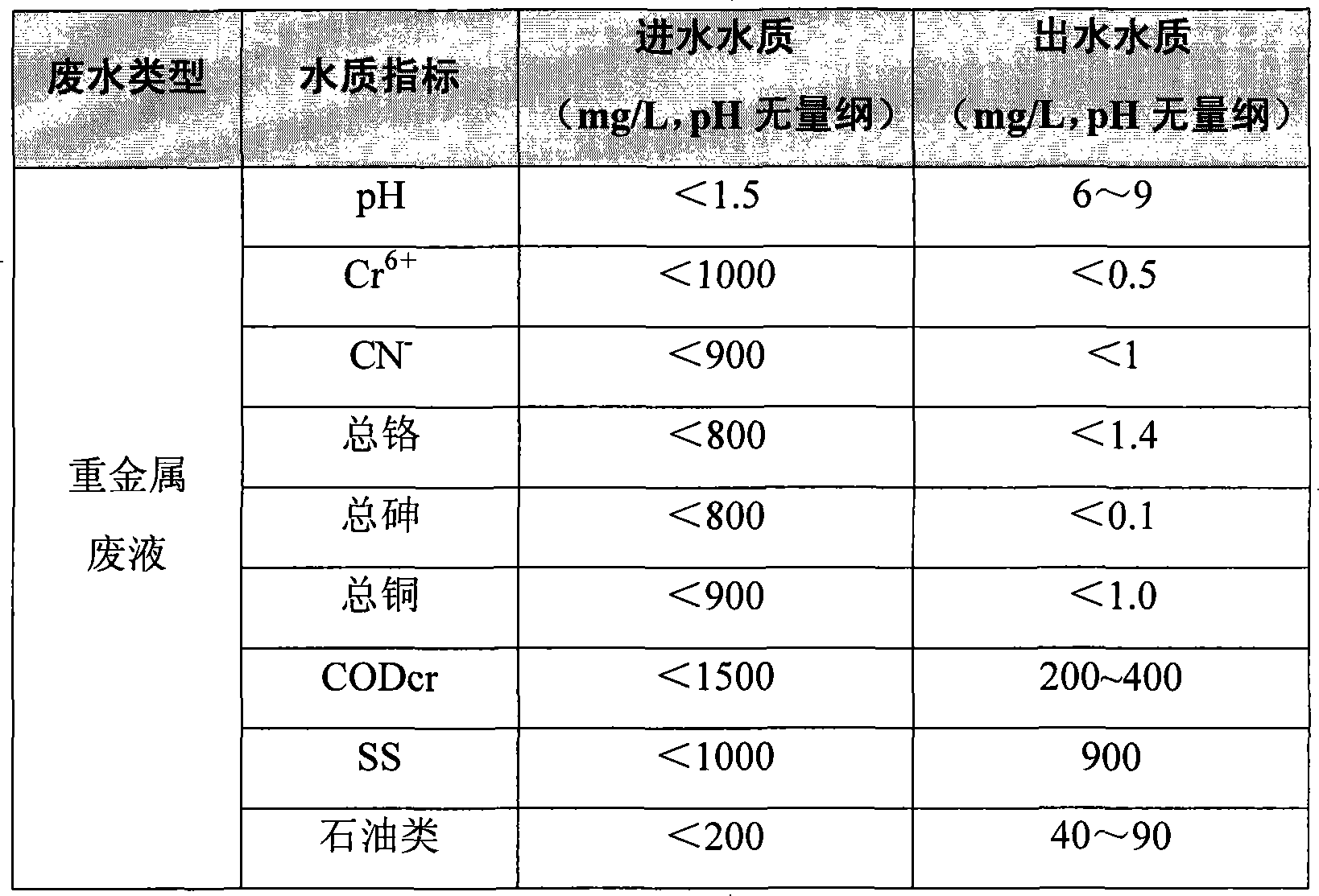

[0028] Example 2: The heavy metal waste liquid from a certain chemical plant is treated with the method and device of the present invention, the treatment capacity is 30.0t / d, and the device runs stably for 1 month. The specific influent water quality and effluent water quality are as follows Table 2 shows.

[0029] 2 Influent and effluent water quality of heavy metal waste liquid

[0030]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com