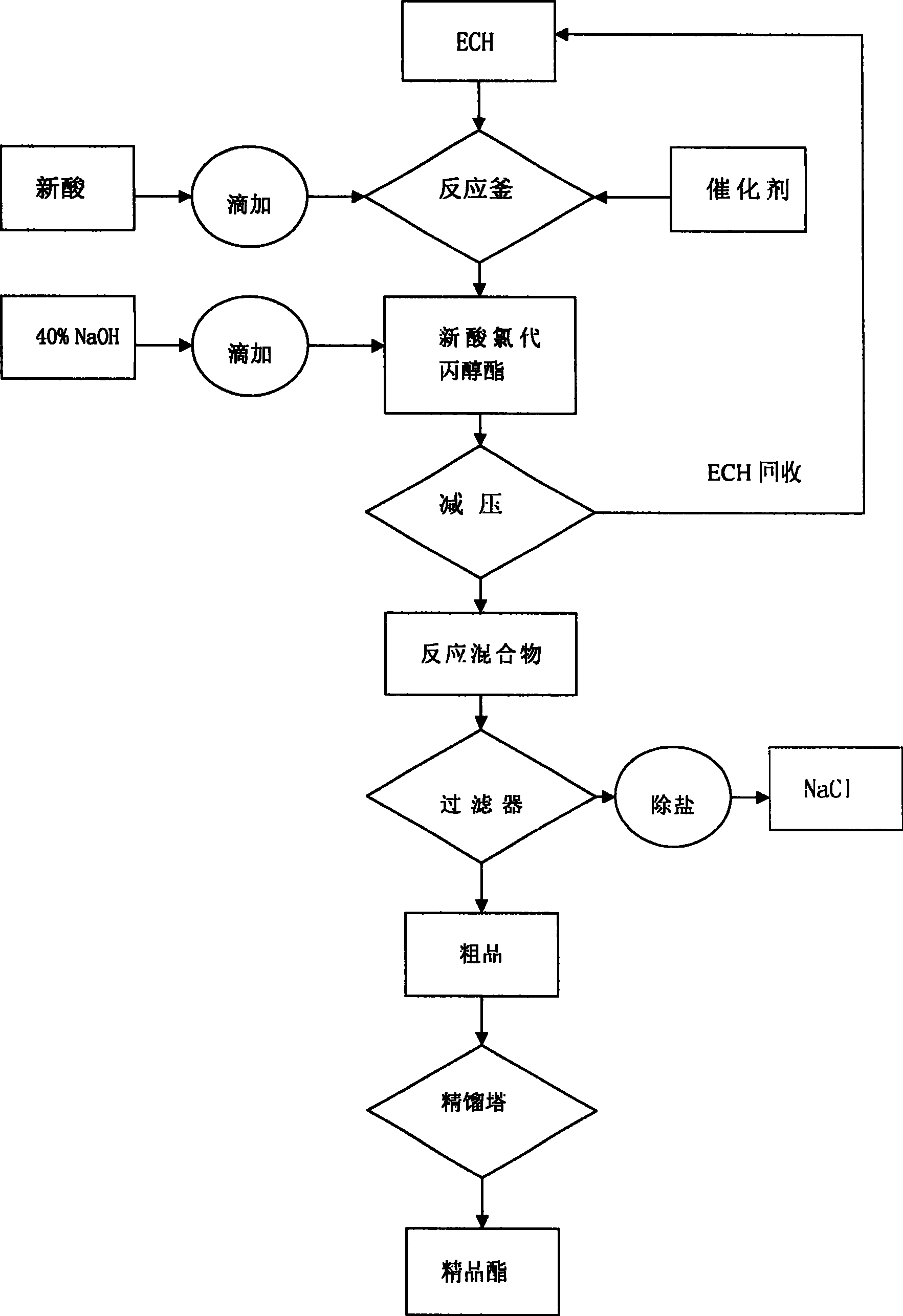

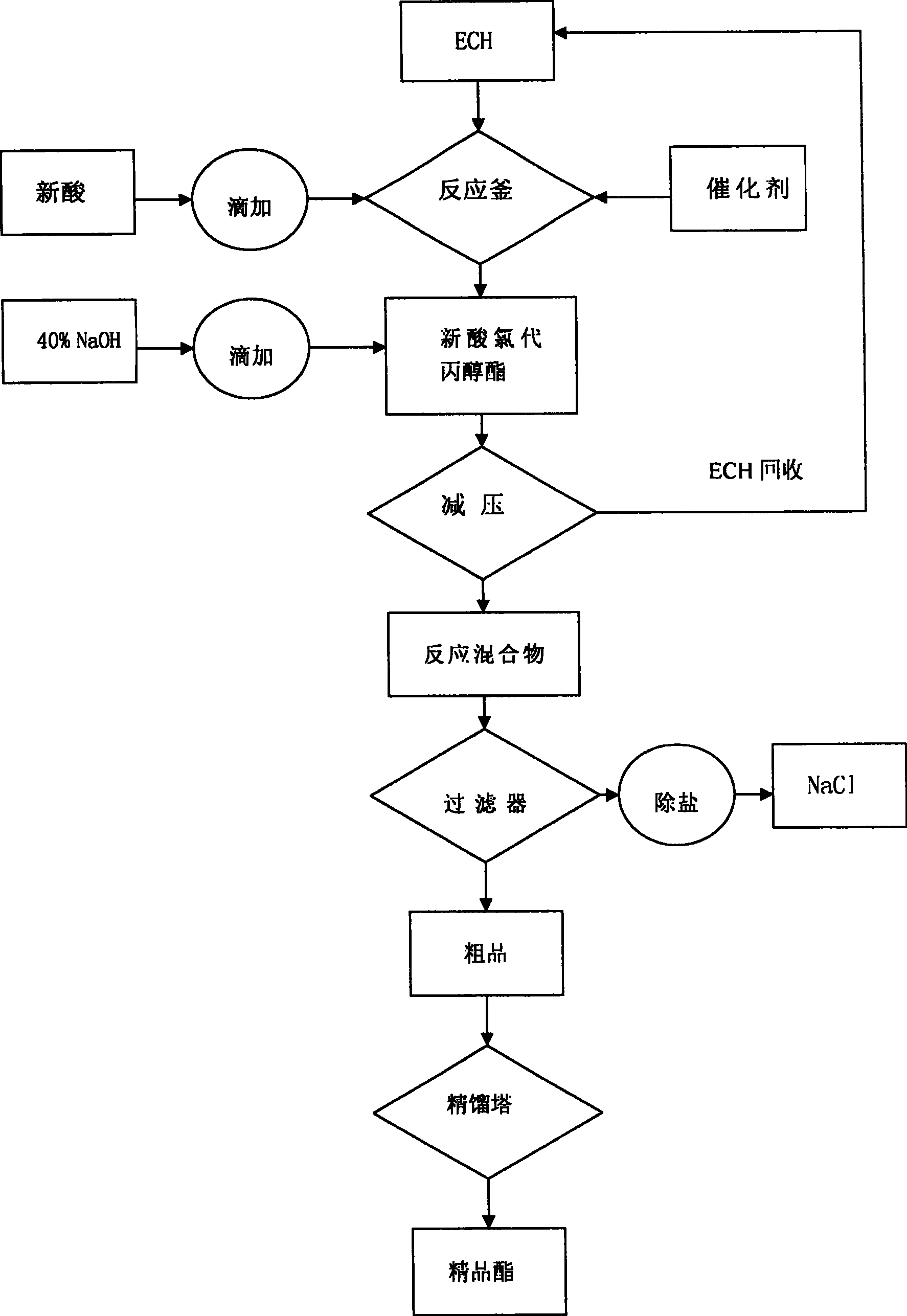

Process for producing tertiary carbonic acid glycidyl ester

A technology of glycidyl ester and tertiary carbonic acid, which is applied in the field of preparation of organic compound glyceride, can solve problems such as impact on product quality and yield, lack of reaction monitoring methods, unstable product quality, etc., and achieve good product quality and simplified operation , the effect of reducing the ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Preparation

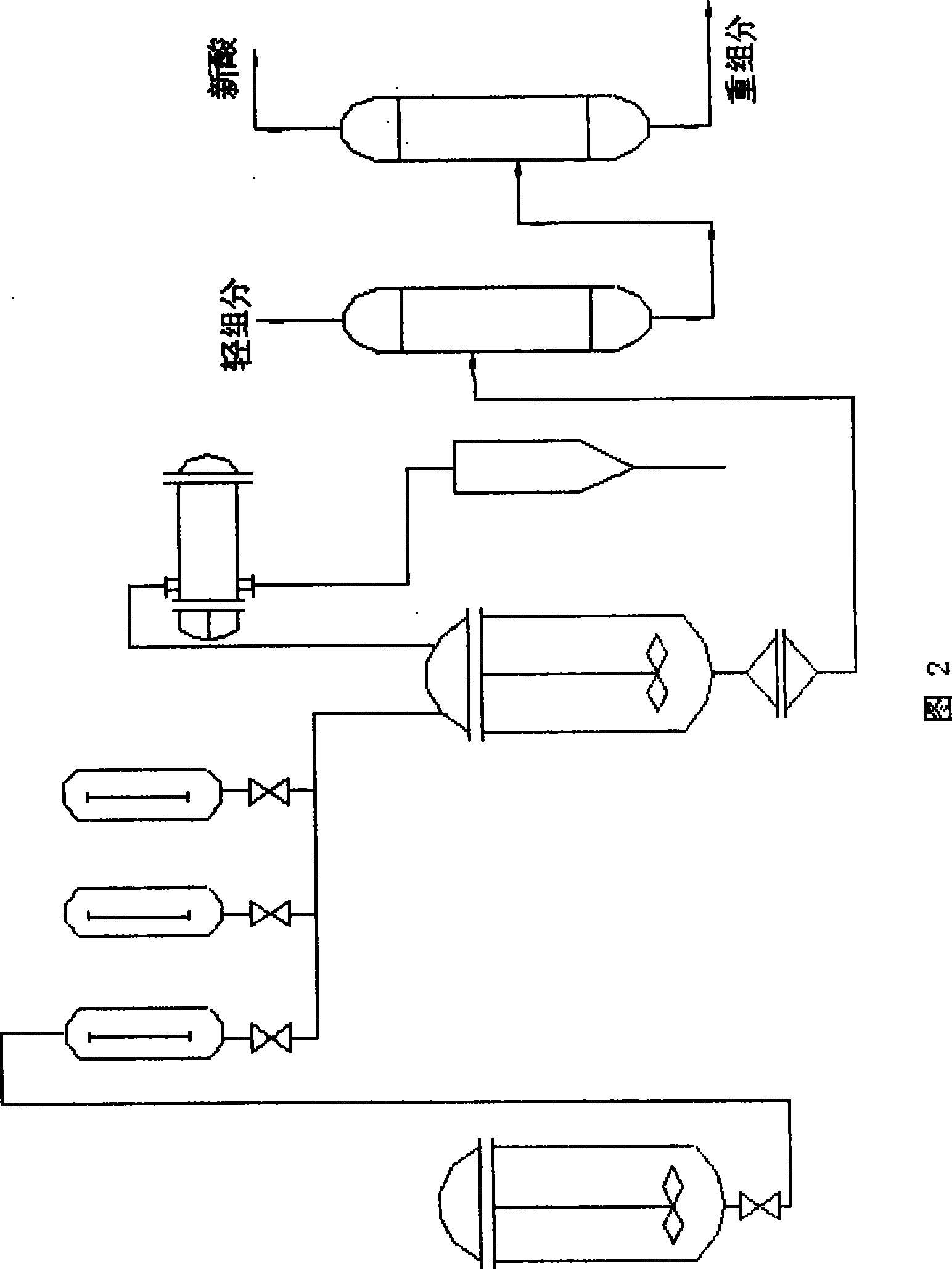

[0035] Major equipment:

[0036] A 1-liter four-neck flask, a mechanical stirrer, a 1-liter temperature-regulating electric heating mantle, a water jet vacuum pump, a rotary vane vacuum pump, a packed rectification column, and several ordinary glass instruments.

[0037] main ingreadient:

[0038] Tertiary carbonic acid C10 (self-made), epichlorohydrin (industrial product), sodium hydroxide (industrial product), catalyst (self-made).

[0039] In a 1-liter four-necked flask equipped with mechanical stirring, after heating 152.6g (1.65mol) of epichlorohydrin and 2.6g of catalyst to 90°C, 258g (1.5mol) of neodecanoic acid was added dropwise, and the rate of addition was controlled so that the temperature Keeping at 90°C, the dropwise addition is completed in about half an hour, and the esterification reaction is completed after the reaction is continued for half an hour. (By measuring the acid value <0.1).

[0040] Contain 66g (1.65mol) 40%NaOH solution t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com