Method for processing vancomycin fermentation waste slag with solid-state fermentation

A technology for solid-state fermentation and fermentation waste residue, which is used in the removal of solid waste, fungi, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Example 1 , the acquisition of yeast seed liquid

[0019] Prepare the seed medium according to the following formula:

[0020] Malt extract powder 8.0%; Yeast powder 0.1%; K 2 HPO 4 0.1%; urea 0.1%; the rest is water; pH6.0.

[0021] After the culture medium was subpackaged and sterilized, various yeasts were added as shown in Table 1, and cultured with shaking at 30°C for 24 hours to obtain yeast seed liquid.

[0022] Table 1

[0023]

Embodiment 2~12

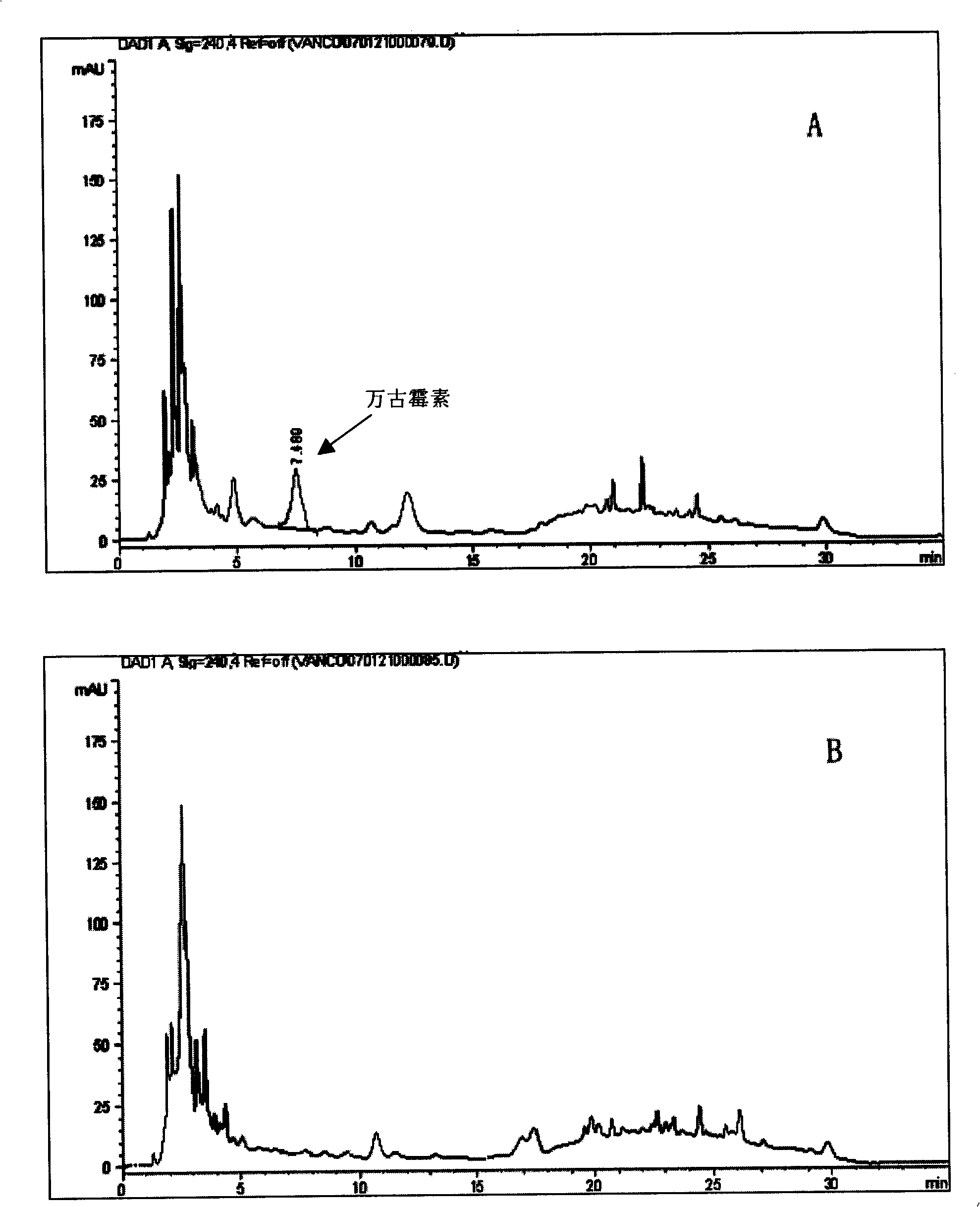

[0024] Embodiment 2~12 , Solid-state fermentation treatment of vancomycin fermentation waste residue

[0025] Take the vancomycin fermentation waste residue, prepare it into a solid medium with an initial water content of ≤80%, and then put it in an oven at 100°C for about 5 minutes for disinfection; then insert the yeast seed solution according to the inoculation amount of about 10% , under the condition of 20-40° C., and cultured statically for 10 hours to 7 days, see Table 2 for details. (Note: Although the conditions and inoculation amount of the above disinfection treatment have been clearly defined, for those skilled in the art, it can be determined according to the actual situation, such as the amount of waste residue, the initial water content of the culture medium and the bacteria in the seed solution. Appropriate adjustments for concentration, etc., are obvious).

[0026] Among them, turn once 12 hours after inoculation, turn again after 24 hours, and turn once ev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com