Method for building over loading railway road-bed on salting ground

A technology for railway subgrade and saline soil, applied in soil protection, roads, roads, etc., can solve problems such as low cost, and achieve the effects of low cost, reduced engineering cost, and shortened construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

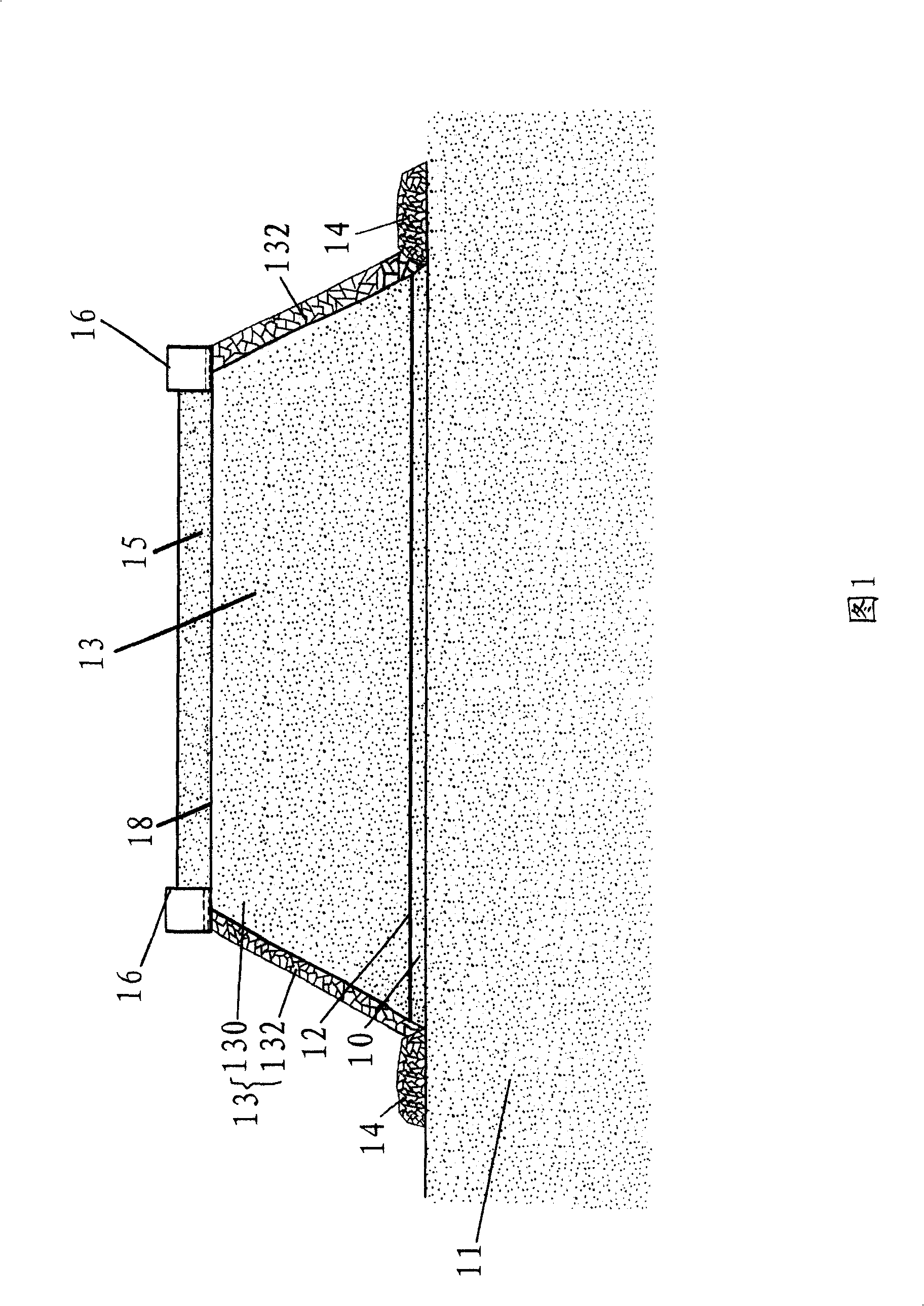

[0022] Please refer to Fig. 1, the method for building heavy-duty railway embankment 1 in saline soil zone of the present invention comprises the following steps:

[0023] First, reinforce the soft soil of foundation 11:

[0024] The saline soil zone is mostly soft soil. Due to the low strength, high compressibility and large void ratio of the soft soil, its foundation stability coefficient and post-construction settlement value cannot meet the construction requirements, so it is necessary to take reinforcement measures for it.

[0025] The specific reinforcement measures are mainly to apply bagged sand wells (not shown), that is, sandbags are inserted into the conduits so that they can be inserted into the foundation 11 along with the conduits, and then the conduits are pulled out to form bagged sand wells. Those skilled in the art can understand that the diameter, layout, number of sand wells, etc. of the bagged sand wells need to be selected according to different topograph...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com