Harmlessness toilet tools

A technology for toilets and drying drums, which can be used in home appliances, sludge treatment through temperature control, sanitary equipment, etc. It can solve the problems of not being able to throw feces and slurry, unfavorable deodorization, and high failure rate of toilets, so as to prevent adhesion Blind zone, ensuring reliability, and improving thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

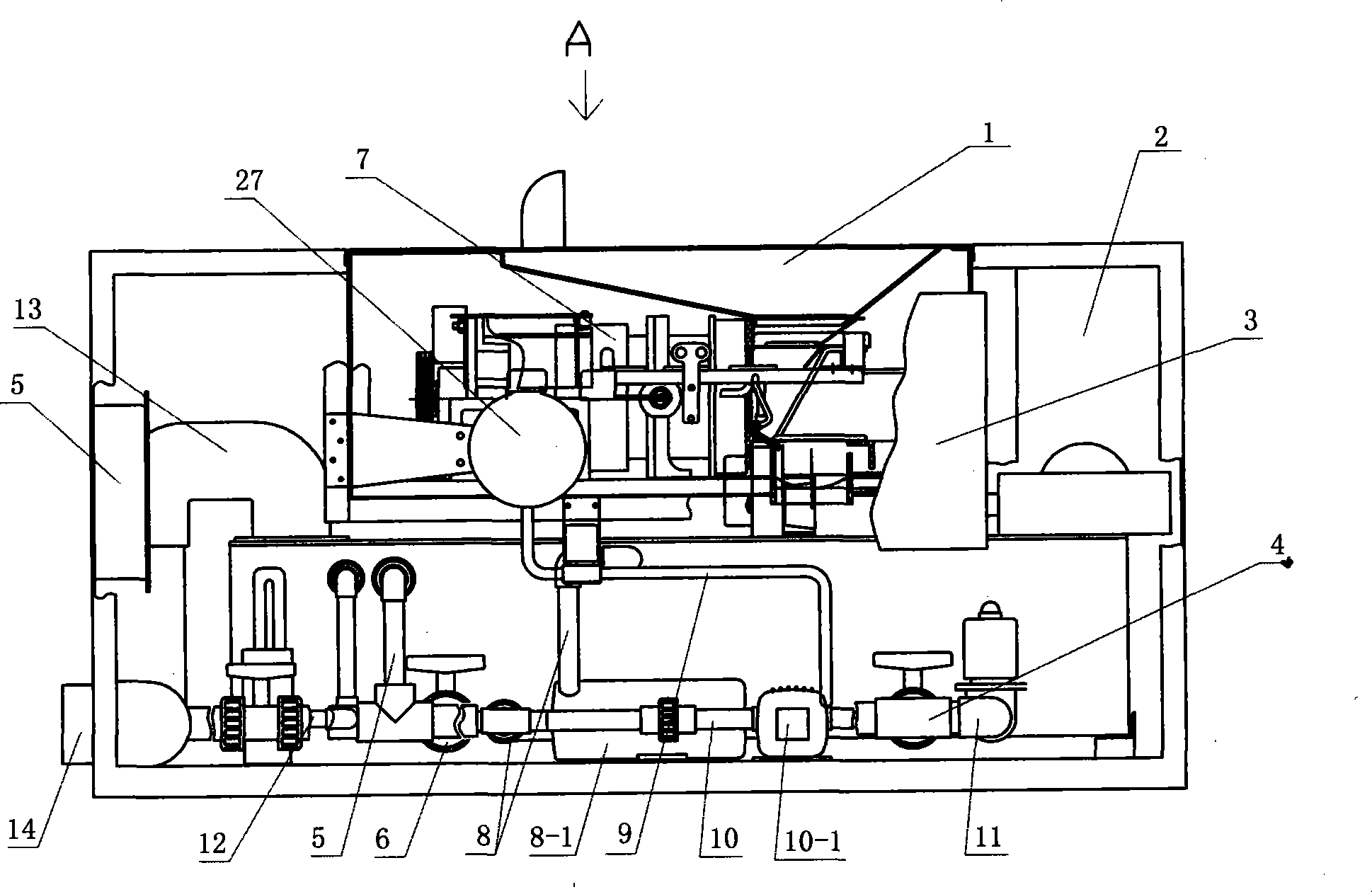

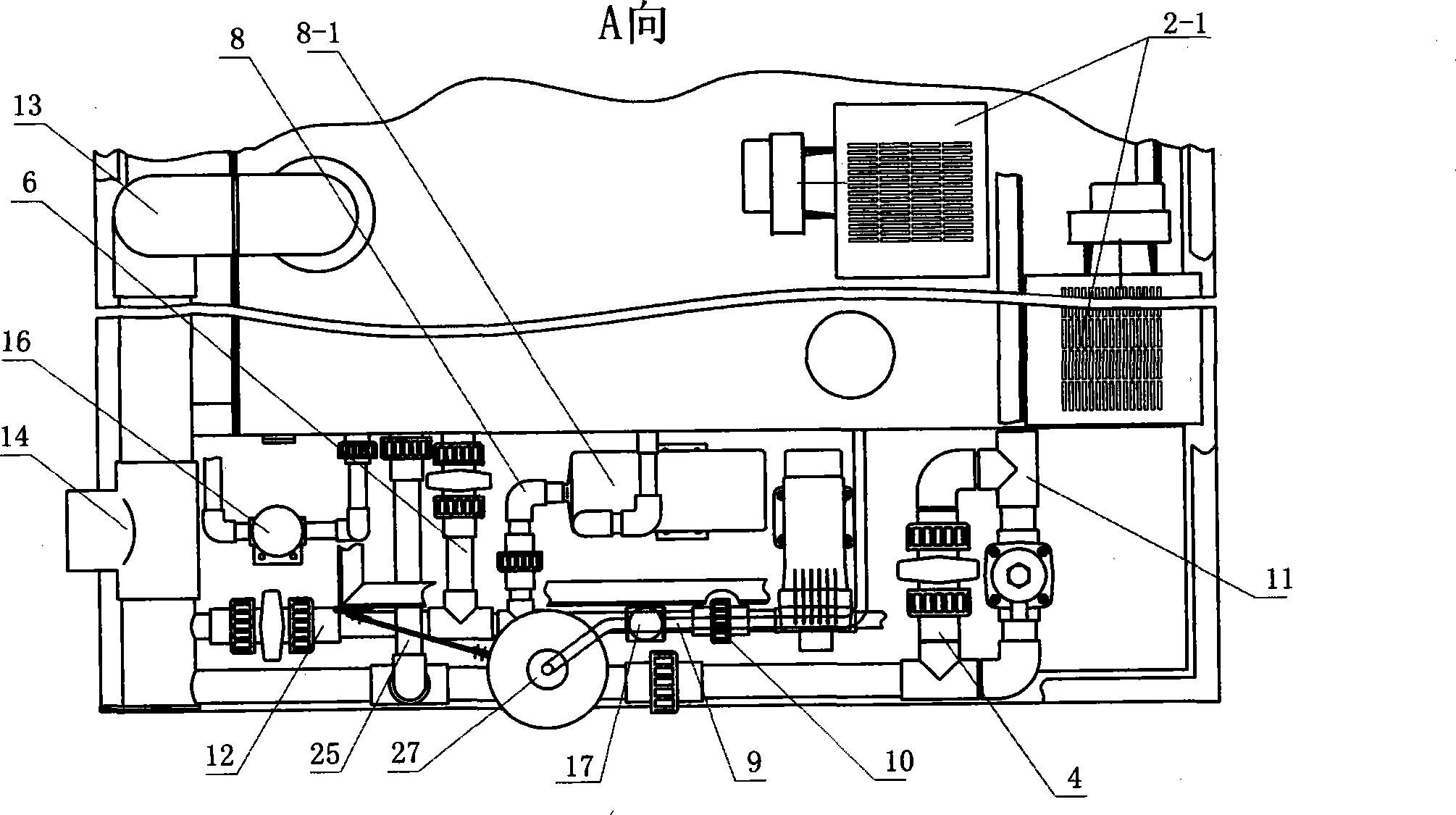

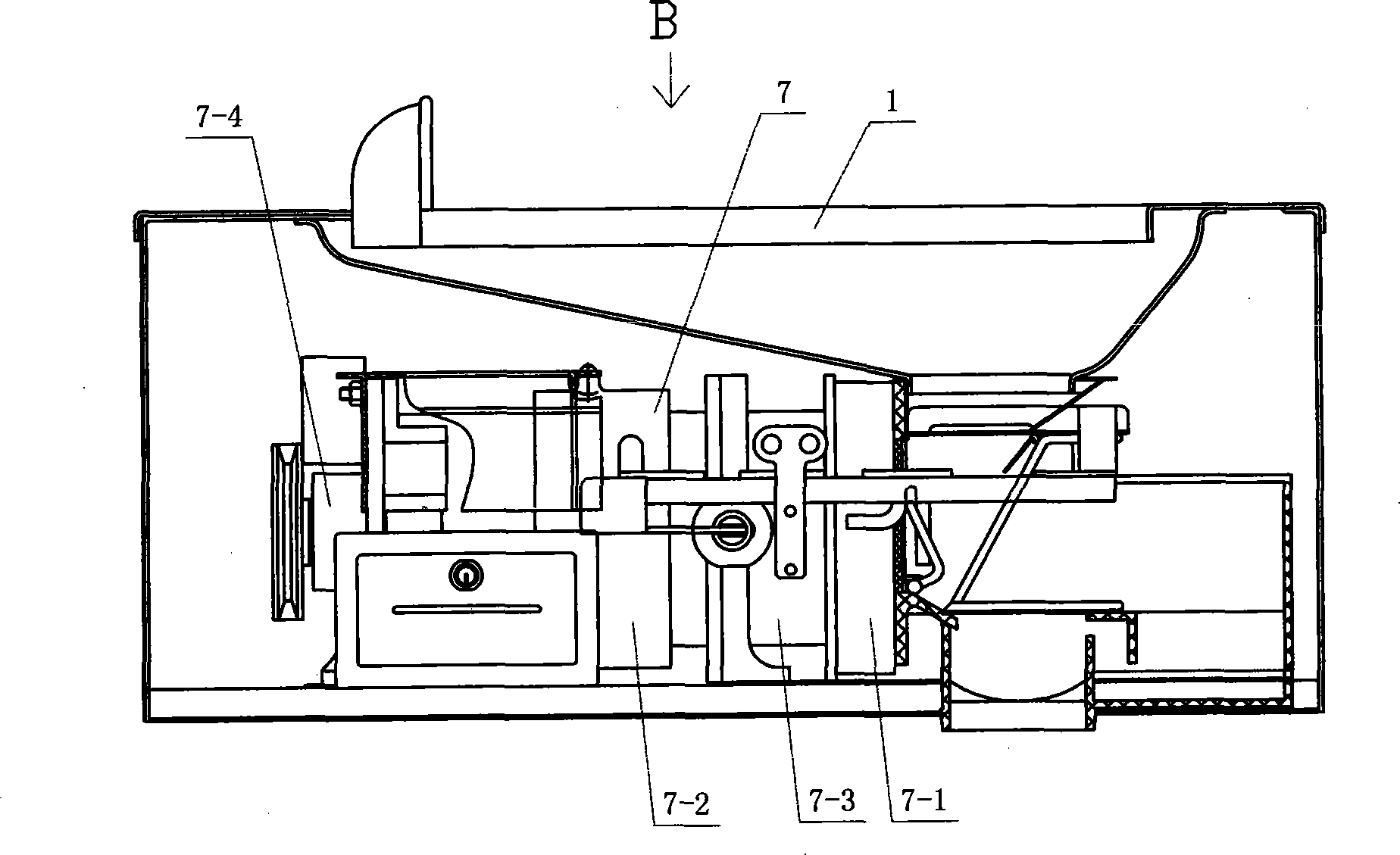

[0035] See Figure 1-4, the harmless toilet of the present embodiment includes: a toilet 1, a feces treatment system 7 located below the toilet 1 and connected to the toilet 1, used to deodorize the odor generated by the feces treatment system 7 The deodorization system 2 of treatment, the water circulation treatment system 4 that cleans and recycles the urine, the water used to clean the toilet 1 and the water participating in the deodorization treatment, and the excrement treatment system 7 for controlling, deodorization The electronic control system 3 of the odor system 2 and the water circulation treatment system 4 working automatically.

[0036] The deodorizing system 2 includes an ozone generator 2-1.

[0037] See Figure 1-4 , the water circulation treatment system 4 has a sealed water tank, which is divided into a sedimentation tank and two cooling tanks, a gap is provided on the upper part of the partition between the two cooling tanks, and a gap is provided on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com