Thermal sublimation digital image ribbon and method for making same

A dye-sublimation and imaging technology, applied in the direction of ink ribbon, printing, ink, etc., to achieve the effect of low cost, clear image and vivid color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

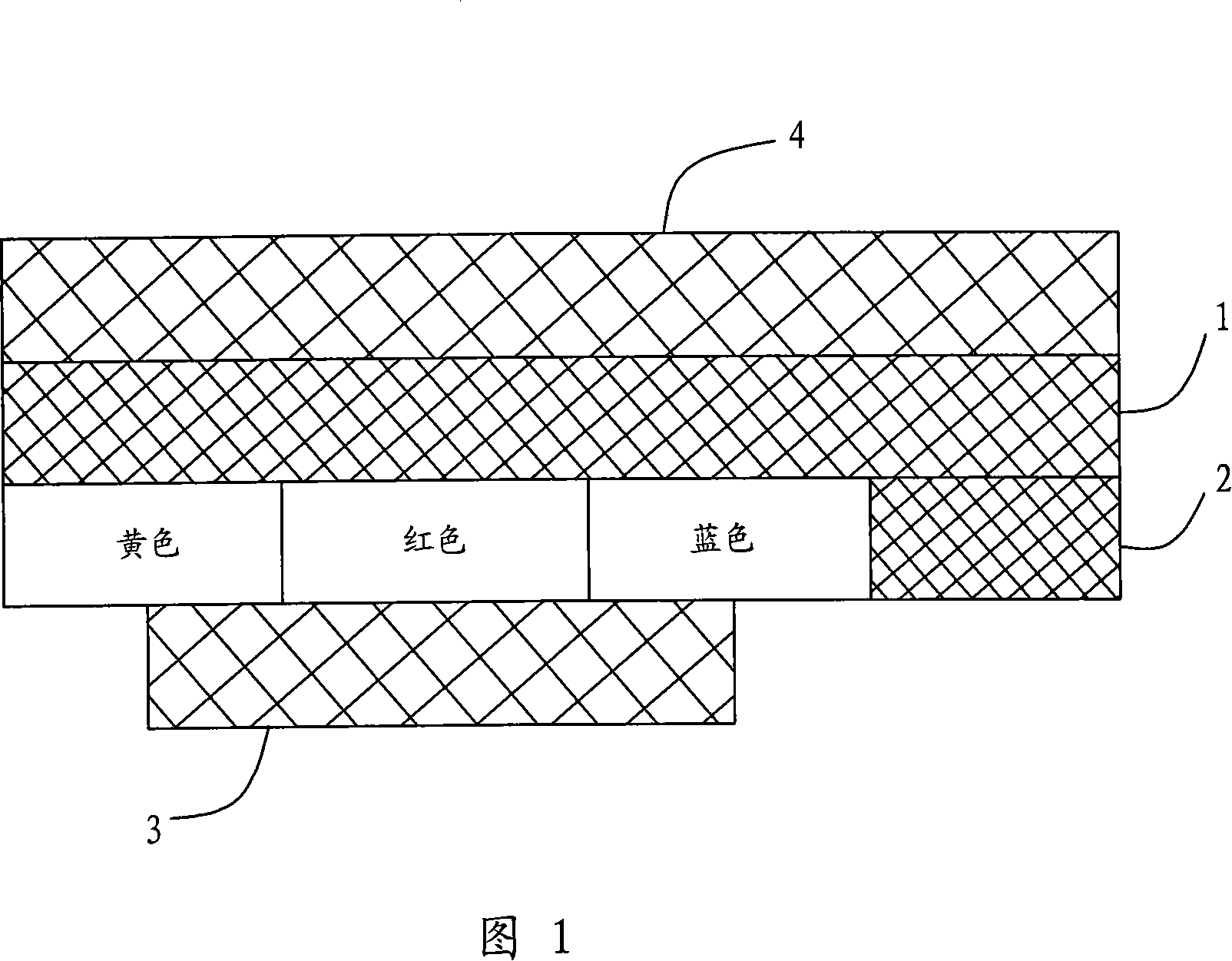

Embodiment 1

[0033] Dissolve and mix 10 parts of polymer dispersant and 60 parts of environmentally friendly solvent for high-speed dispersion, then put in 5 parts of grinding aid, 10 parts of acrylic resin and 15 parts of sublimation dye yellow 86 for high-speed dispersion, and then carry out high-speed dispersion. Nanoscale grinding to obtain a yellow slurry for the ink layer. Use a gravure coater to coat the thermoplastic resin and ink slurry on one side of the polyester film as the base tape according to the process requirements, and coat the polyester modified silicone resin on the other side of the polyester film to obtain a sublimation digital image ribbon.

Embodiment 2

[0035] Dissolve and mix 8 parts of polymer dispersants and 60 parts of environmentally friendly solvents for high-speed dispersion, and then add 7 parts of grinding aids, 10 parts of acrylic resin and 15 parts of sublimation dye red 180 to carry out high-speed dispersion. Grade grinding to obtain the red slurry of the ink layer. Use a gravure coater to coat the thermoplastic resin and ink slurry on one side of the polyester film as the base tape according to the process requirements, and coat the polyester modified silicone resin on the other side of the polyester film to obtain a sublimation digital image ribbon.

Embodiment 3

[0037] Dissolve and mix 12 parts of polymer dispersant and 58 parts of environmentally friendly solvent for high-speed dispersion, then add 5 parts of grinding aid, 10 parts of acrylic resin and 15 parts of sublimation dye blue 199 for high-speed dispersion. Grinding to obtain the blue slurry of the ink layer. Use a gravure coater to coat the thermoplastic resin and ink slurry on one side of the polyester film as the base tape according to the process requirements, and coat the polyester modified silicone resin on the other side of the polyester film to obtain a sublimation digital image ribbon.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com