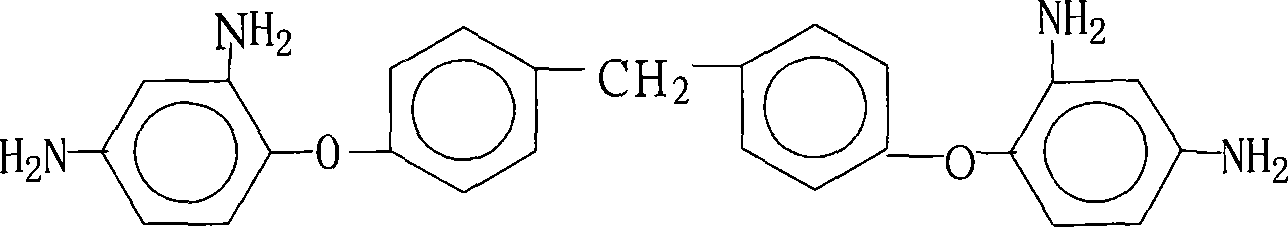

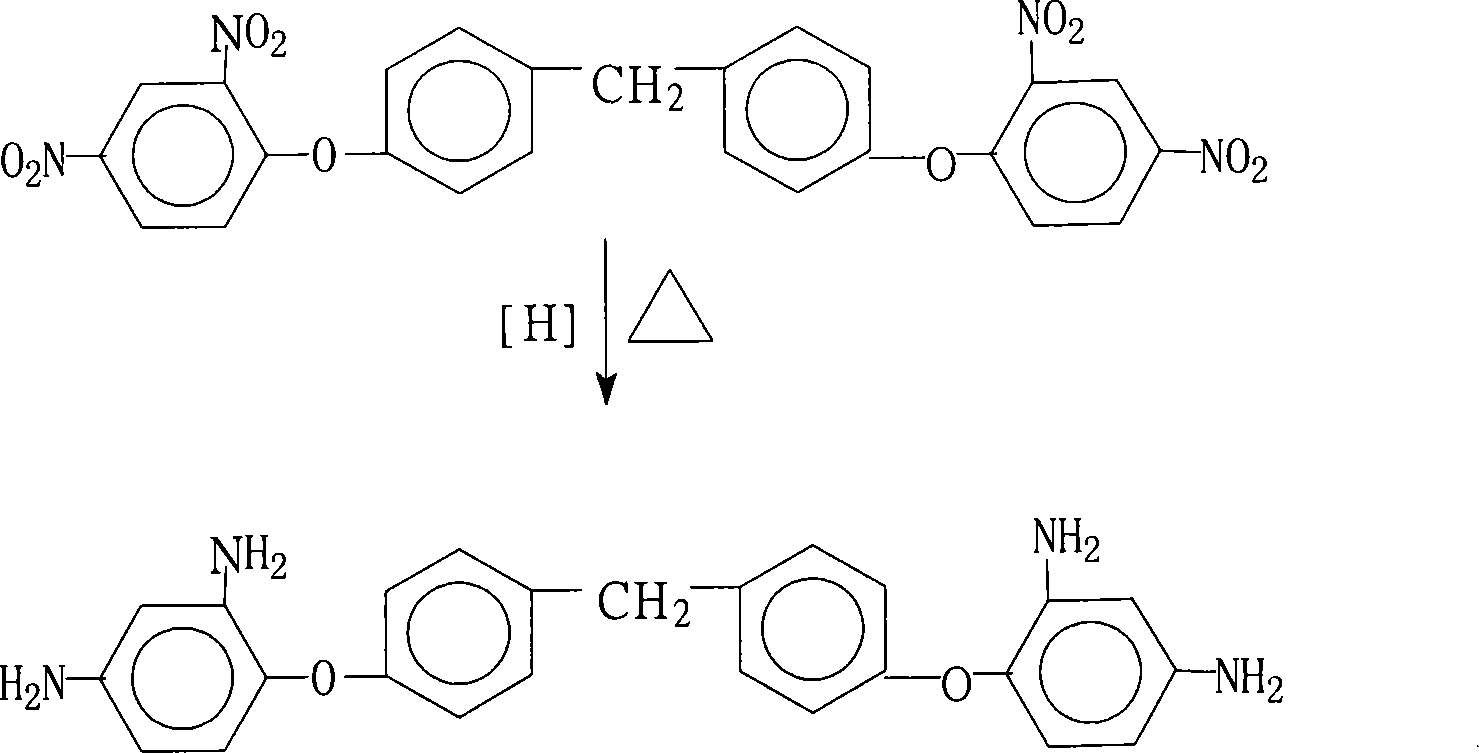

Method for preparing 4,4-di(2,4-diamino phenoxy) diphenylmethane

A technology of diaminophenoxy and dinitrophenoxy, applied in 4 fields, can solve the problems such as no patents, literature reports and the like in the preparation method, and achieve the effects of convenient source of raw materials, less three wastes, and obvious energy saving and consumption reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] 53.2 grams (0.1 mole) of 4,4'-bis(2,4-dinitrophenoxy)diphenylmethane, 0.5 gram of palladium mass percentage is 15% palladium / carbon, 800 milliliters of ethanol and 1600 ml of ethylene glycol are added In the reaction flask, stir, heat up to 60° C., and start to add dropwise a hydrazine hydrate solution with a mass concentration of 60% (the molecular weight of hydrazine hydrate is 50.06), totaling 250.0 grams (solution weight). After the dropwise addition of hydrazine hydrate was completed, the stirring reaction was continued for 5 hours at a temperature range of 80°C to 90°C, cooled slightly, filtered while hot, cooling the mother liquor, adding pure water, the crystallized product was precipitated, filtered, and vacuum-dried to obtain 38.9 grams of 4 , 4'-bis(2,4-diaminophenoxy)diphenylmethane crystals with a purity of 99.8%, according to the actual obtained 4,4'-bis(2,4-diaminophenoxy)diphenylmethane The amount and the theoretical amount (41.2 g), the calculated yield...

Embodiment 2

[0029] 53.2 grams (0.1 moles) of 4,4'-bis(2,4-dinitrophenoxy)diphenylmethane, 10.0 grams of palladium mass percentage is 1% palladium / carbon, 100ml ethylene glycol and 2000ml ethanol are added to the reaction In the bottle, stir, heat up to 60° C., start to add dropwise a mass concentration of 85% hydrazine hydrate solution, a total of 294.1 grams (solution weight). After the dropwise addition of hydrazine hydrate was completed, the stirring reaction was continued within the temperature range of 80°C to 90°C for 3.5 hours, cooled slightly, filtered while hot, cooled mother liquor, added pure water, precipitated crystalline product, filtered, and vacuum-dried to obtain 37.6 grams of 4 , 4'-bis(2,4-diaminophenoxy)diphenylmethane crystals with a purity of 99.7%, according to the actual obtained 4,4'-bis(2,4-diaminophenoxy)diphenylmethane The amount and the theoretical amount (41.2 grams), the calculated yield of 4,4'-bis(2,4-diaminophenoxy)diphenylmethane was 91.2%.

Embodiment 3

[0031] 53.2 grams (0.1 moles) of 4,4'-bis(2,4-dinitrophenoxy)diphenylmethane, 5.0 grams of palladium mass percent palladium / carbon 200 milliliters of ethanol and 1000 milliliters of 2-methoxy Add base ethanol in the reaction flask, stir, heat up to 60° C., and start to add dropwise a hydrazine hydrate solution with a mass concentration of 80%, totaling 260.0 grams (solution weight). After the dropwise addition of hydrazine hydrate is completed, continue stirring and reacting for 1 hour at a temperature range of 80°C to 90°C, cool slightly, filter while hot, cool the mother liquor, add pure water, precipitate a crystalline product, filter, and vacuum dry to obtain 32.2 grams of 4 , 4'-bis(2,4-diaminophenoxy)diphenylmethane crystals with a purity of 99.4%, according to the actual obtained 4,4'-bis(2,4-diaminophenoxy)diphenylmethane The amount and the theoretical amount (41.2 grams), the calculated yield of 4,4'-bis(2,4-diaminophenoxy)diphenylmethane was 78.2%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com