Method for making aluminum foil adhesive tape

A production method and adhesive tape technology, applied in the direction of adhesives, film/sheet adhesives, etc., can solve the problems of high production cost, large amount of raw materials, and restrictions on the high temperature resistance of adhesive tapes, so as to ensure high temperature resistance performance, shorten the production process, and save raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

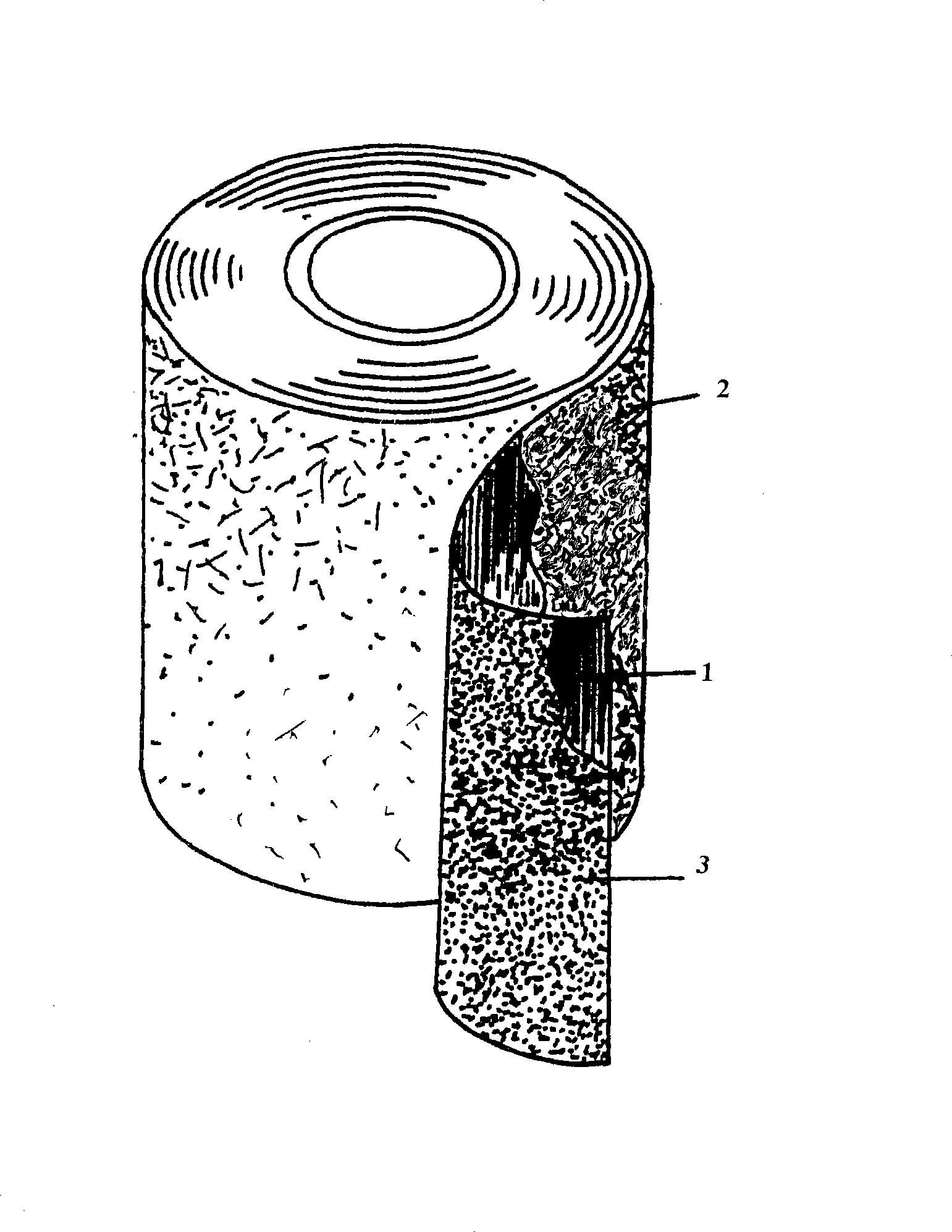

[0022] A). Select high-quality aluminum foil substrate 1;

[0023] B). Use a coating machine to coat the surface of one side of the aluminum foil substrate 1 with silicone oil, and while coating, it is dried in an oven at a temperature of 90°C, so that the surface of one side of the aluminum foil substrate 1 forms silicone oil. Layer 2, wherein: silicone oil is composed of 1 part of dibutylene dilaurate, 2 parts of ethyl orthosilicate, 9 parts of silicone oil, 20 parts of silicone rubber, 60 parts of polyethylene resin, 120 parts of acetone and 600 parts of toluene are organic silicone oil that is uniformly stirred by manual or mechanical stirring at normal temperature and pressure. The yellow resin used as silicone oil is preferably 107 yellow resin produced by China Shanghai Resin Research Institute. Described silicone rubber is commercially available trade mark and is 107 silicone rubbers;

[0024] C). Place it at room temperature for 48 hours after winding out of the dryi...

Embodiment 2

[0028] A). Select high-quality aluminum foil substrate 1;

[0029] B). Use a coating machine to coat the surface of one side of the aluminum foil substrate 1 with silicone oil, and while coating, it is dried in an oven at a temperature of 115°C, so that the surface of one side of the aluminum foil substrate 1 forms silicone oil. Layer 2, wherein: silicone oil is composed of: 1 part of dibutylene dilaurate, 1.5 parts of ethyl orthosilicate, 11 parts of silicone oil or yellow resin, 25 parts of silicone rubber, 65 parts of polyethylene resin, 130 parts of acetone and 650 parts of toluene are organic silicone oil that is uniformly stirred by manual or mechanical stirring at normal temperature and pressure. The yellow resin used as silicone oil is preferably 107 yellow resin produced by China Shanghai Resin Research Institute. Described silicone rubber is commercially available trade mark and is 107 silicone rubbers;

[0030] C). Place it at room temperature for 50 hours after wi...

Embodiment 3

[0034] A). Select high-quality aluminum foil substrate 1;

[0035] B). Use a coating machine to coat the surface of one side of the aluminum foil substrate 1 with silicone oil, and while coating, it is dried in an oven at a temperature of 125°C, so that the surface of one side of the aluminum foil substrate 1 forms silicone oil. Layer 2, wherein: silicone oil is composed of 1 part of dibutylene dilaurate, 1.8 parts of ethyl orthosilicate, 12 parts of silicone oil or yellow resin, 28 parts of silicone rubber, and 68 parts of polyvinyl chloride resin. 145 parts of acetone and 700 parts of toluene are uniformly stirred by hand or mechanically under normal temperature and pressure. The yellow resin used as the silicone oil is preferably 107 yellow resin produced by the Shanghai Resin Research Institute of China. , the silicone rubber is a commercially available brand of 107 silicone rubber;

[0036] C). Place it at room temperature for 64 hours after winding out of the drying tun...

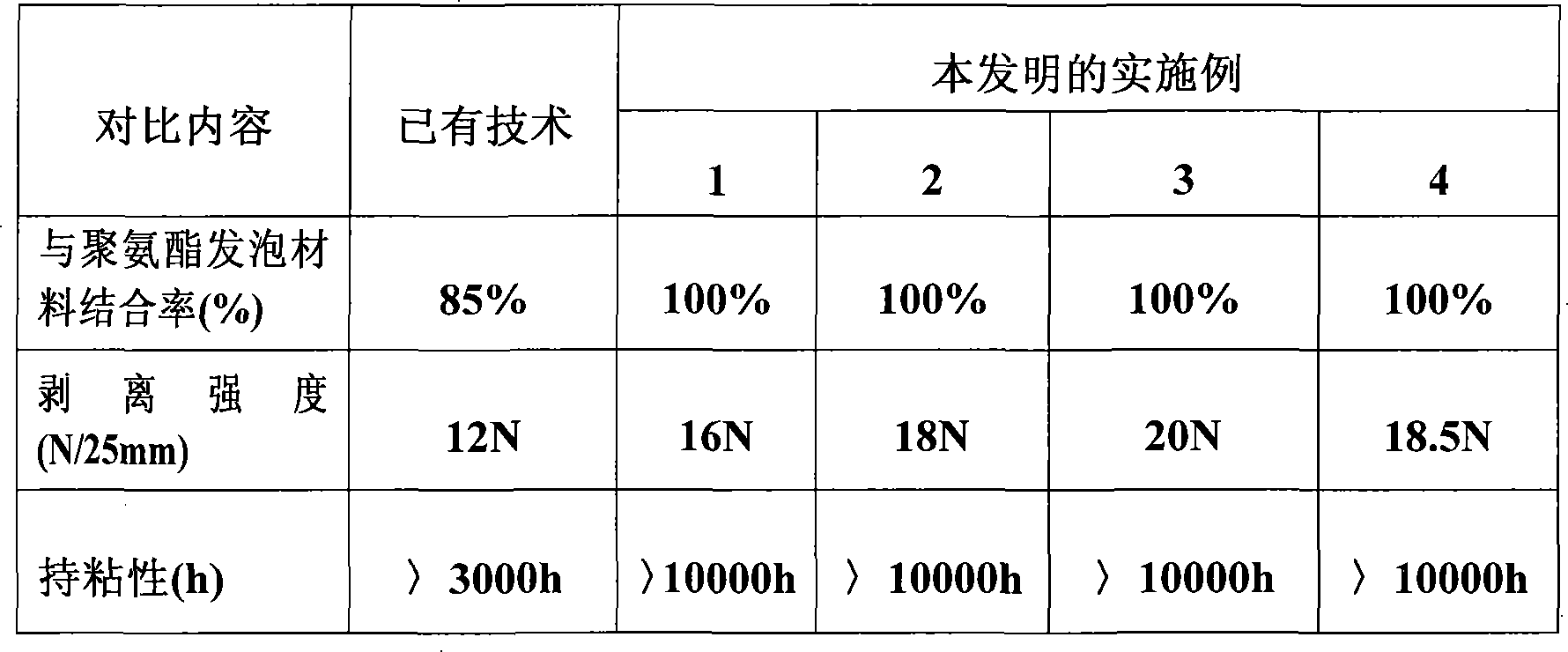

PUM

| Property | Measurement | Unit |

|---|---|---|

| peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com