Catalytic conversion deoxidation method of coal-bed gas

A catalytic conversion and coal bed gas technology, applied in the field of deoxidation, can solve the problems of low cooling efficiency, lower energy utilization rate, and difficulty in using by-product steam, and achieve the effect of increasing heat and improving cooling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

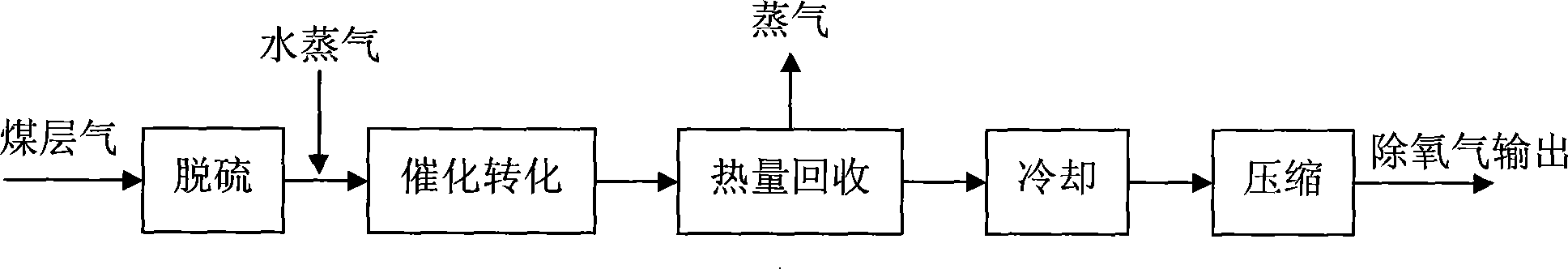

[0023] The technical process of the coal bed gas catalytic conversion deoxidation method in this embodiment is as follows figure 1 Shown:

[0024] After desulfurizing raw coalbed methane 100NM3, add a small amount of water vapor to make H 2 O / CH 4 (molar ratio, the same below)=0.3, pass in the deoxidation reactor, in SiO 2 In the presence of a Ni-based catalyst as a carrier, a catalytic conversion deoxygenation reaction is carried out;

[0025] The pressure of the deoxidation reaction is 0.60MPa, and the inlet temperature of the deoxidation reactor is 400°C.

[0026] The composition (vol%) of raw coal bed gas is: CH 4 50%, O 2 10%, N 2 40%.

[0027] The gas outlet temperature after the reaction was 650°C.

[0028] The dry gas composition (vol%) after the reaction is: CH 4 25.73%, N 2 31.30%, H 2 29.57%, CO 8.37%, CO 2 5.03%.

[0029] The gas volume after reaction is 127.8Nm 3 , the calorific value of the mixed gas (higher calorific value, the same below) 1...

Embodiment 2

[0033] The technical process of the coal bed gas catalytic conversion deoxidation method in this embodiment is as follows figure 1 Shown:

[0034] After desulfurizing raw coalbed methane 100NM3, add a small amount of water vapor to make H 2 O / CH 4 (molar ratio, the same below)=0.2, pass in the deoxidation reactor, in Al 2 o 3 In the presence of a Ni-based catalyst as a carrier, a catalytic conversion deoxygenation reaction is carried out;

[0035] The pressure of the deoxidation reaction is 0.45MPa, and the inlet temperature of the deoxidation reactor is 400°C.

[0036] The composition (vol%) of raw coal bed gas is: CH 4 40%, O 2 12%, N 2 48%.

[0037] The gas outlet temperature after the reaction was 693°C.

[0038] The dry gas composition (vol%) after the reaction is: CH 4 14.66%, N 2 36.70%, H 2 32.72%, CO 12.64%, CO 2 3.28%.

[0039] The gas volume after reaction is 130.9Nm 3 , the calorific value of the outlet gas is 11.60MJ / Nm 3 .

[0040] The coo...

Embodiment 3

[0043] The technical process of the coal bed gas catalytic conversion deoxidation method in this embodiment is as follows figure 1 Shown:

[0044] After desulfurizing raw coalbed methane 100NM3, add a small amount of water vapor to make H 2 O / CH 4 (molar ratio, the same below)=0.5, pass in the deoxidation reactor, in Al 2 o 3 In the presence of a Ni-based catalyst as a carrier, a catalytic conversion deoxygenation reaction is carried out;

[0045] The pressure of the deoxidation reaction is 0.6MPa, and the inlet temperature of the deoxidation reactor is 400°C.

[0046] The composition (vol%) of raw coal bed gas is: CH 4 50%, O 2 10%, N 2 40%.

[0047] The gas outlet temperature after the reaction was 632.6°C.

[0048] The dry gas composition (vol%) after the reaction is: CH 4 24.93%, N 2 30.47%, H 2 31.45%, CO 6.72%, CO 26.63%.

[0049] The gas volume after reaction is 131.3Nm 3 , the calorific value of the mixed gas (high calorific value, the same below) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com