Polyurethane heat-preserving composition board and manufacturing method

A production method, polyurethane technology, applied in thermal insulation, chemical instruments and methods, synthetic resin layered products, etc., can solve the problems of safety impact, shedding, heavy weight, etc., and achieve good bearing capacity, good decorative effect, and light weight Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

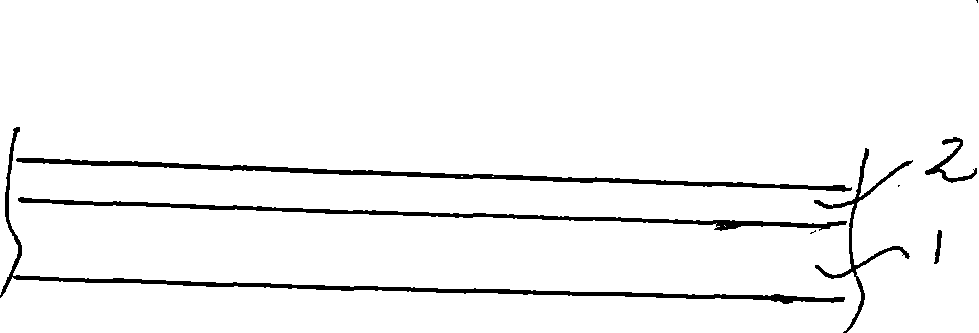

[0023] A polyurethane thermal insulation composite board is produced according to the following process: various conventional raw materials are prepared according to conventional ratios, the mold is closed, and then pouring and foaming are performed by a pouring machine. A high-density and high-hardness self-skinned polyurethane rigid foam board 1 is obtained, and its hardness is Shore 70D. Then apply polyurethane adhesive on its non-skinning side, and stick the low-density polyurethane rigid foam plastic plate 2 on its surface immediately. After the adhesive is cured, the polyurethane insulation composite board can be obtained.

Embodiment 2

[0025] A polyurethane thermal insulation composite board is produced according to the following process: various conventional raw materials are prepared according to conventional ratios, the mold is closed, and then pouring and foaming are performed by a pouring machine. A high-density and high-hardness self-skinned polyurethane rigid foam plastic plate is obtained, and its hardness is Shore 70D. Then use it as a bottom plate, put it into another mold, and perform foaming of conventional low-density polyurethane board on its non-skinning side to obtain a polyurethane thermal insulation composite board.

Embodiment 3

[0027] A polyurethane thermal insulation composite board, which is produced according to the following process: various conventional raw materials are prepared according to conventional ratios, and glass fiber or nano-calcium carbonate is added in an amount of 4-8% of the total weight of all the above-mentioned raw materials (minimum Preferably 6%) short glass fibers or nanometer calcium carbonate as reinforcing material, close the mold, and then use a pouring machine to pour and foam. A high-density and high-hardness self-skinned polyurethane rigid foam plastic plate is obtained, and its hardness is Shore 70D. Then use it as a bottom plate, put it into another mold, and perform foaming of conventional low-density polyurethane board on its non-skinning side to obtain a polyurethane thermal insulation composite board.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com