Thermal drive deforming transmission electric mirror grid and one-dimensional nano material deforming method

A technology of transmission electron microscopy and nanomaterials, which is applied in the direction of circuits, discharge tubes, electrical components, etc., can solve the problems of application limitations, poor controllability, and poor controllability of curling, and achieve the effects of simple structure, convenient installation, and reliable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

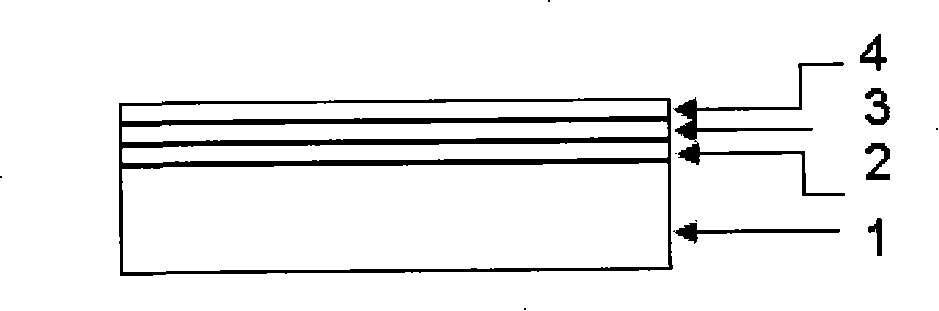

[0025] Using the conventional physical evaporation coating process to make thermally driven deformable transmission electron microscope grids, such as figure 1 As shown, a support film (2) (carbon film) is laid on the skeleton (1) (copper mesh), and a metal film A (3) and a metal film B (4) are vapor-deposited on the upper surface of the support film (2) in sequence; Wherein, the metal film A (3) is made of Mn72Ni10Cu18 alloy, the metal film B (4) is made of Ni36Fe64 alloy, the thickness of the metal film A (3) is 30nm, and the thickness of the metal film B (4) is 30nm.

[0026] Deformation of one-dimensional nanomaterials using thermally driven deformable TEM grids:

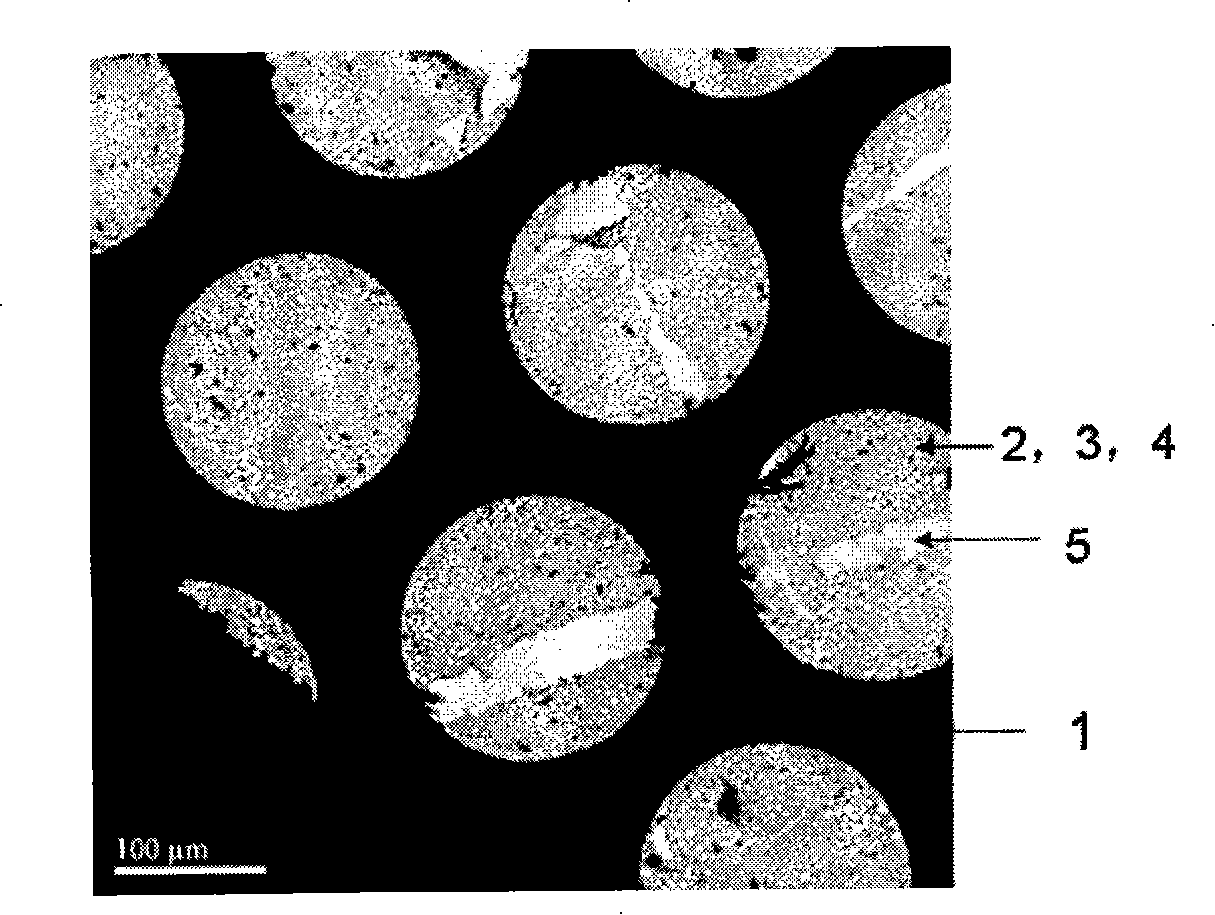

[0027] 1) Prefabricate some microcracks (5) on the metal films A (3) and B (4) of the grid with a blade, such as figure 2 As shown, the black area is the skeleton (1) (copper mesh), the gray round hole area is the support film (2) (carbon film), metal film A (3) and metal film B (4), and the blank area is the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com